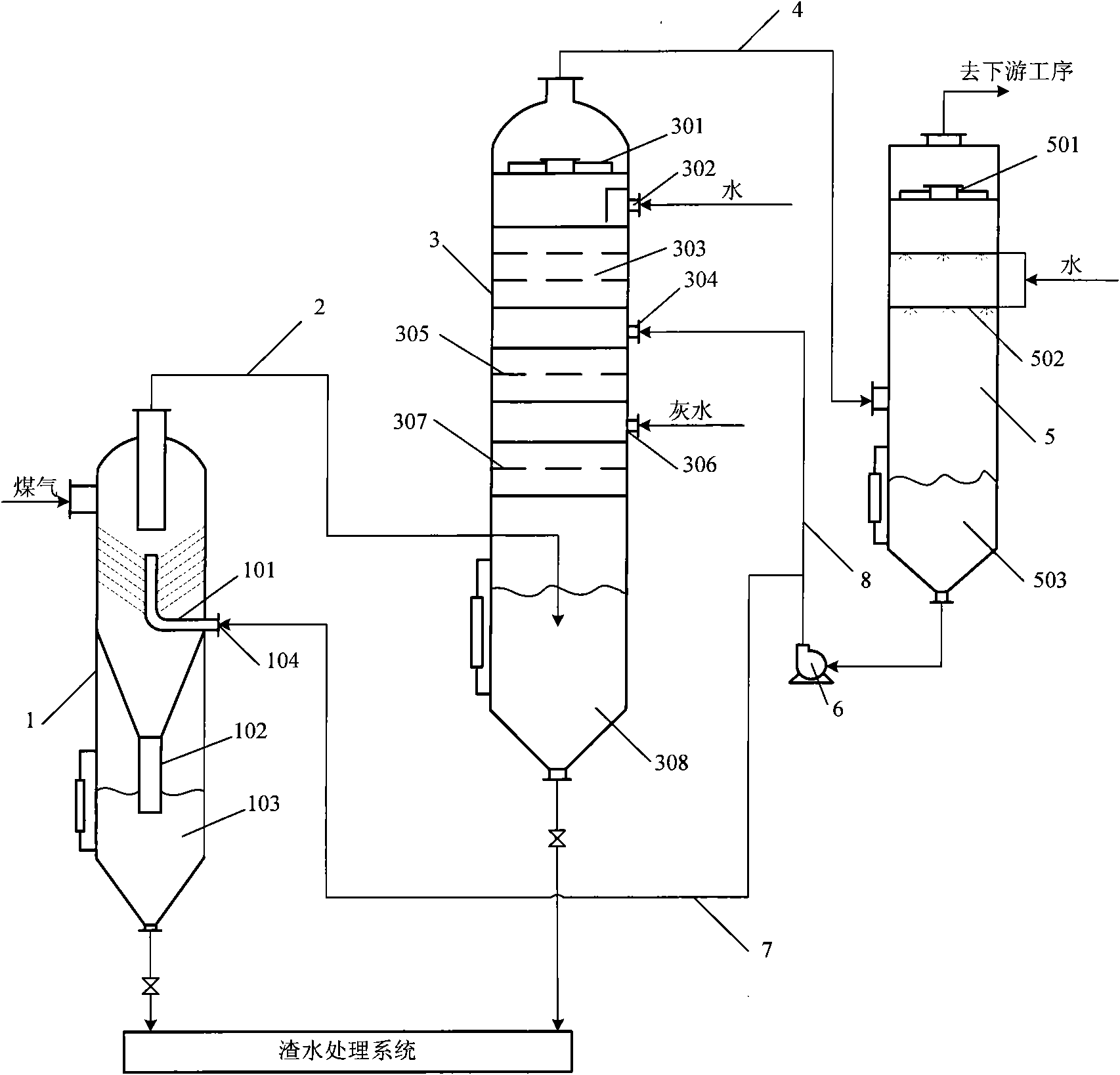

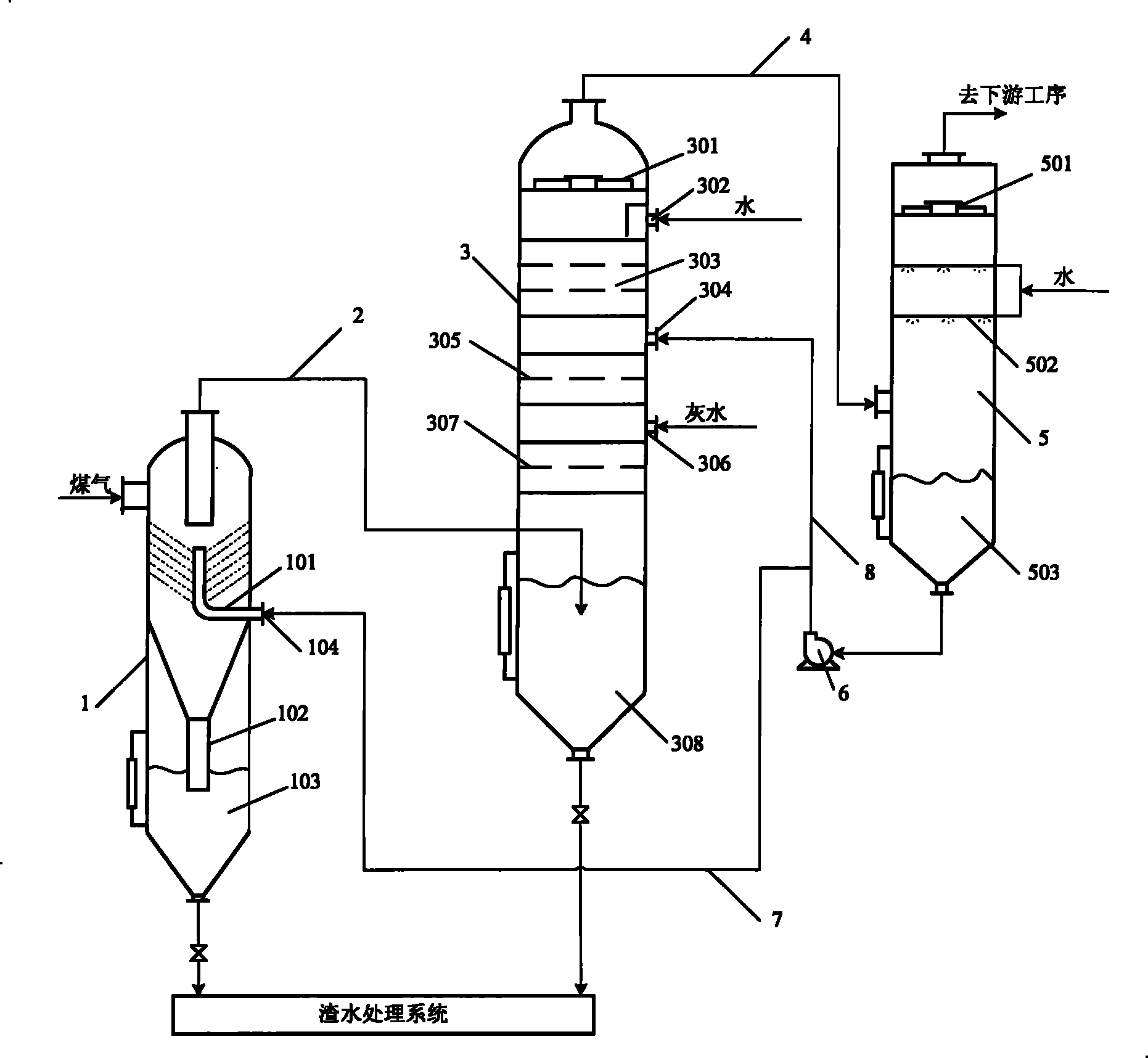

Coal gas purifying device

A purification device and gas technology, applied in the direction of combustible gas purification, combustible gas purification/transformation, and production of combustible gas, etc. The effect of convenient maintenance, high flexibility in operation and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The chilled pulverized coal pressurized gasification device with a daily processing capacity of 1,000 tons of coal has a gasification pressure of 4.0MPa and a gasification temperature of 1550°C. 73000Nm 3 / h, wet base flow rate is 187500Nm 3 / h, the ash content in dry gas is 7g / Nm 3 . The gas pressure entering the cyclone scrubber is 3.98MPa, the temperature of the circulating gray water is 190°C, and the water volume is 30t / h. The gas is mixed with gray water, and the steam condenses in a small amount of wet gas. The gas enters from the inlet of the cyclone scrubber 1, and under the wetting of the spray water and the centrifugal force, 95% of the gray water containing slag enters the lower liquid storage tank 103 through the downcomer 102 along the inner wall of the cyclone scrubber 3, and the slag water flows from the storage tank. The bottom of the liquid tank 103 is discharged into the slag water treatment system, and the wet gas that removes most of the ash ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com