Purification cup

A water cup and liner technology, applied in the field of water treatment, can solve the problems of poor purification effect, more than 8.5, and high water power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

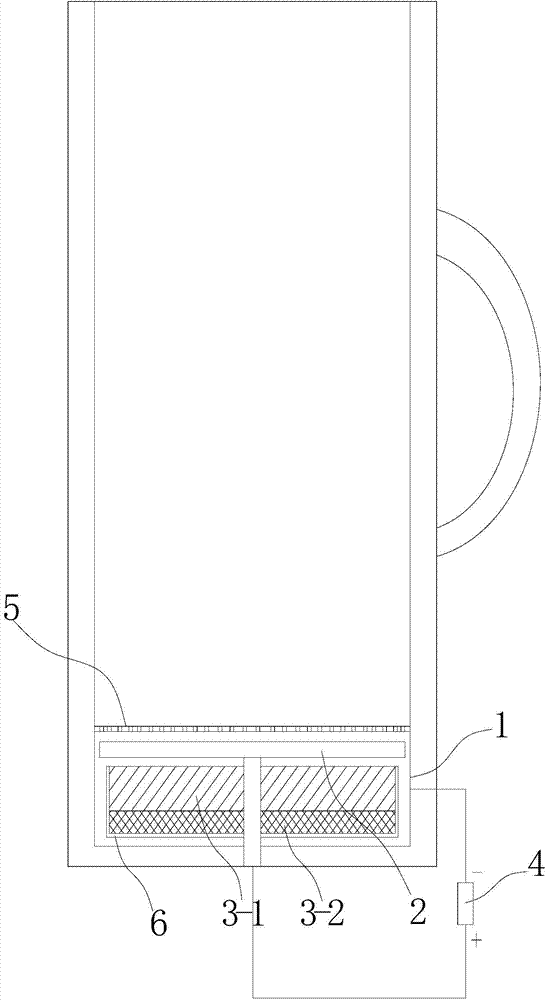

[0022] The purified water cup of present embodiment sees figure 1 , including an inner pot 1 with a water filling port and a pouring port on the top and a power supply 4, the inner pot 1 is made of stainless steel and directly serves as a cathode electrode, and the power source 4 uses a 24V asymmetrical alternating pulse electrolysis power supply.

[0023] An anode 2 is arranged at the inner bottom of the liner 1 , and a porous hydrophobic plate 5 is arranged on the anode 2 . The anode is an inert electrode that is sprayed with platinum group oxide on a titanium plate, and the anode 2 and the liner 1 (that is, the cathode) are respectively connected to the positive and negative electrodes of the power supply 4 .

[0024] Near the anode electrode 2 in the liner 1, there are secondary filter layers with conductivity from low to high in the direction of water flow, which are activated carbon fiber filter membrane 3-1 and ultrafiltration membrane 3-2 respectively. The secondary f...

Embodiment 2

[0031] The purified water cup of this embodiment is basically the same as the first embodiment, the difference is: 1) the inner tank 1 is not directly used as the cathode electrode, but the cathode electrode surrounding the inner wall of the inner tank 1 is separately set in the inner tank 1; 2) in the inner tank 1 The joint surface of activated carbon fiber filter membrane 3-1 and ultrafiltration membrane 3-2 is coated with bamboo charcoal with a thickness of 2 mm that has been treated with nano-activation and uniform mesopore modification as the third filter layer. The fineness of bamboo charcoal is about 60-80 mesh .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com