Deep treatment method of gold hydrometallurgy cyanide-containing wastewater

A technology of hydrometallurgy and advanced treatment, applied in the field of metallurgy, can solve the problems of low recycling rate, high cost, long process flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

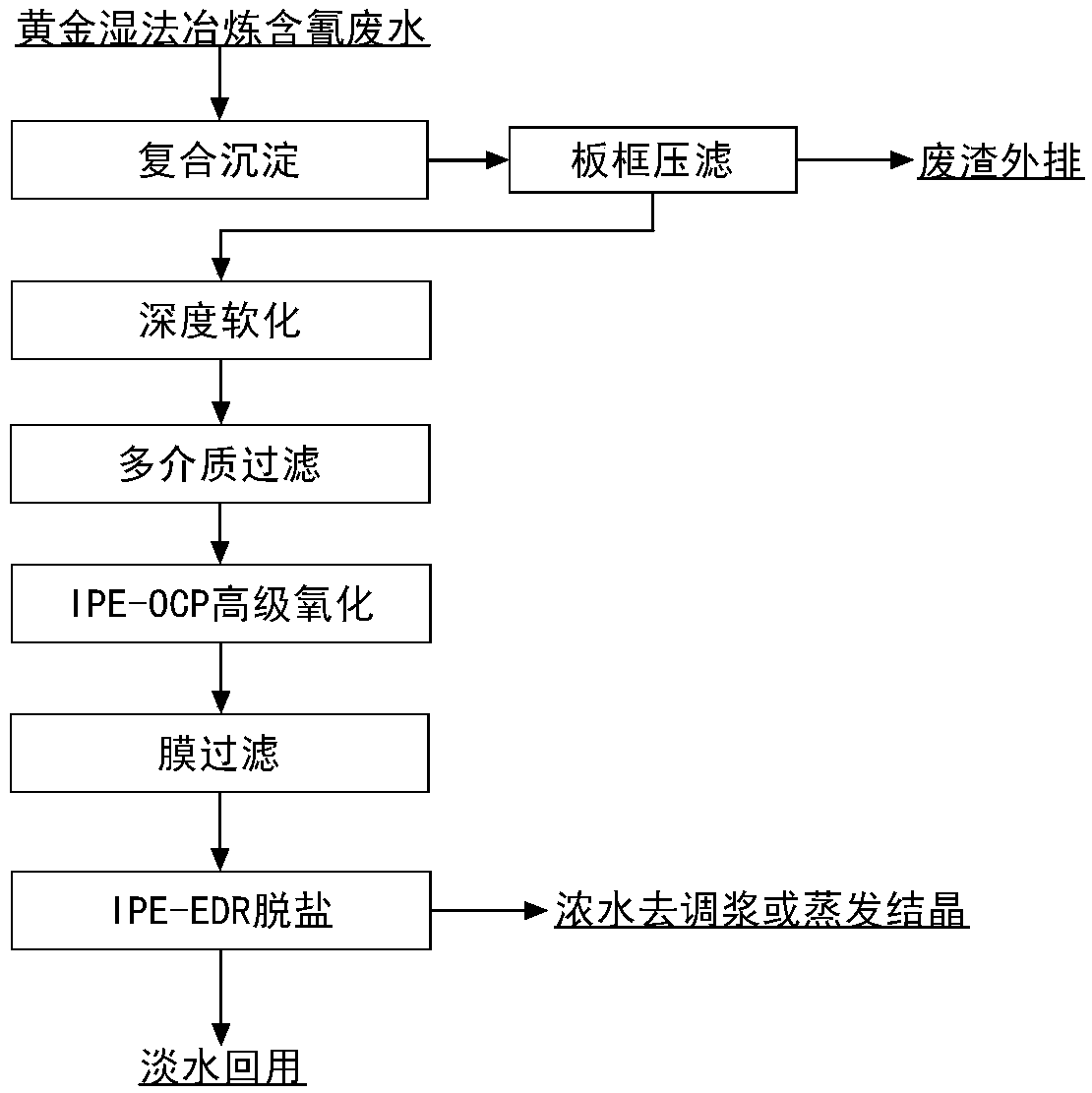

Method used

Image

Examples

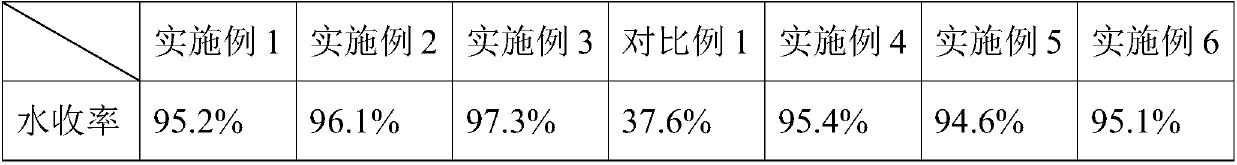

Embodiment 1

[0052] A method for advanced treatment of cyanide-containing wastewater from gold hydrometallurgy, the steps are as follows:

[0053] (1) Take the low-concentration cyanide-containing wastewater after the gold hydrometallurgy cyanide-containing wastewater is pretreated by the lime neutralization method, the total cyanide concentration is reduced to 10mg / L, the concentration of soluble salt is 65g / L, and the COD content is 650mg / L , the content of ammonia nitrogen is 70mg / L, and the content of heavy metal elements is 10mg / L; a composite precipitant is added to the wastewater, and the composite precipitant includes a chemical precipitant, an inorganic flocculant, an organic flocculant, and a chemical precipitant with a mass ratio of 1:1:0.01. The precipitant includes sodium sulfide and quicklime; the inorganic flocculant is aluminum sulfate; the organic flocculant is an organic polymer flocculant; the ratio of the quality of the composite precipitant to the volume of low-concentr...

Embodiment 2

[0058] A method for advanced treatment of cyanide-containing wastewater from gold hydrometallurgy, the steps are as follows:

[0059] (1) Treat gold hydrometallurgy cyanide-containing wastewater through SO 2- Low-concentration cyanide-containing wastewater after pretreatment by air method (total cyanide concentration is reduced to 0.5mg / L, soluble salt concentration is 90g / L, COD content is 300mg / L, ammonia nitrogen content is 30mg / L, heavy metal element content 100mg / L), the composite precipitant includes chemical precipitant, inorganic flocculant, organic flocculant and active aluminum with a mass ratio of 1:50:0.5, and the chemical precipitant includes ammonium sulfide and calcium hydroxide; The inorganic flocculant is ferric chloride; the organic flocculant is a microbial flocculant; the ratio of the quality of the composite precipitant to the volume of low-concentration cyanide-containing wastewater is 5.0 g / L, and the waste residue is filtered out after the precipitation...

Embodiment 3

[0064] A method for advanced treatment of cyanide-containing wastewater from gold hydrometallurgy, the steps are as follows:

[0065] (1) Low-concentration cyanide-containing wastewater (total cyanide 5mg / L, soluble salt concentration of 40g / L, COD content of 100mg / L) obtained after pretreatment of gold hydrometallurgy cyanide-containing wastewater by acidification volatilization-alkali absorption method L, the content of ammonia nitrogen is 120mg / L, and the content of heavy metal elements is 50mg / L) by adding a composite precipitant. The composite precipitant includes a chemical precipitant, an inorganic flocculant, an organic flocculant and an active Aluminum, chemical precipitants include ferrous sulfide and calcium carbide slag; inorganic flocculants are polyferric sulfate; organic flocculants are organic polymer flocculants and microbial flocculants; the ratio of the mass of composite precipitants to the volume of low-concentration cyanide-containing wastewater It is 2g / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com