Rapid treating method for rare earth radioactive wastewater

A radioactive wastewater and rare earth technology, which is applied in the rapid treatment of rare earth radioactive wastewater, uranium radioactive wastewater, and thorium-containing fields, can solve the problems of low removal rate, easy generation of dirt, short service life, etc., and achieve good application prospects and strong adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

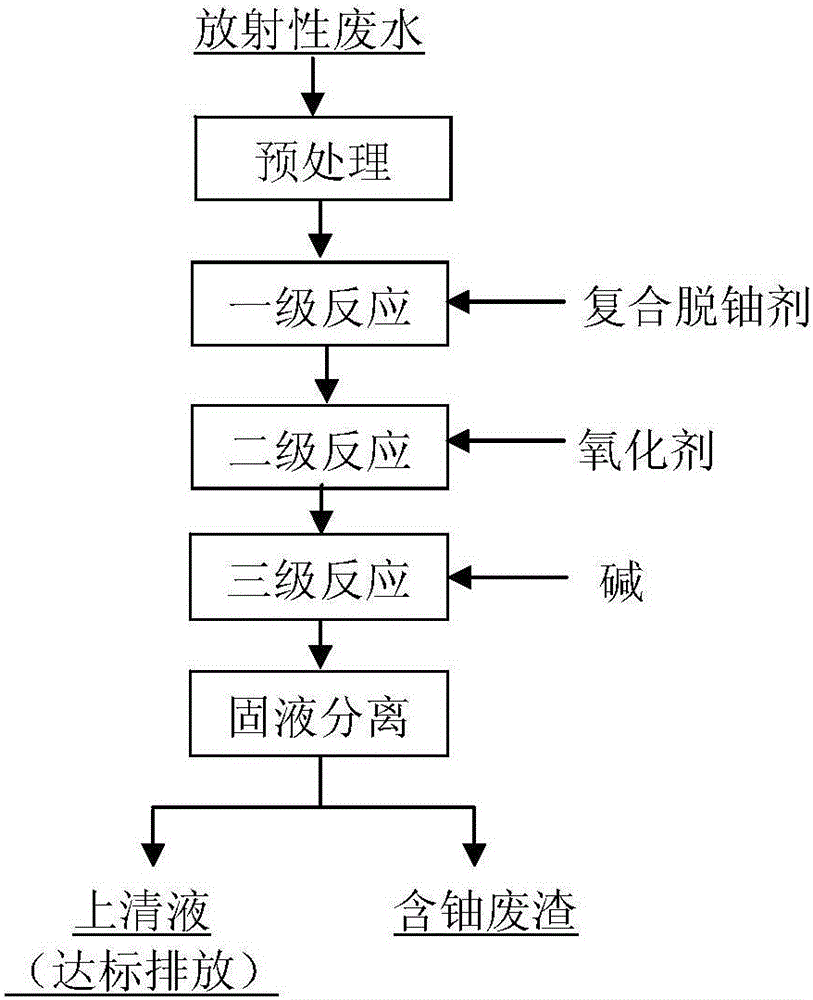

Method used

Image

Examples

Embodiment 1

[0030] Preparation of composite deuranium agent:

[0031] a, the polyferric sulfate (Fe 2 (OH)n(SO 4 ) 3~n / 2 ) m , ferric chloride (FeCl 3 ·6H 2 O), ferrous nitrate (Fe(NO 3 ) 2 ·6H 2 O), ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O), ferrous perchlorate (Fe(ClO 4 ) 2 ), potassium ferrate (K 2 FeO 4 ), polyaluminum sulfate [Al 2 (OH)m(SO 4 ) 3- ] n , aluminum sulfate (Al 2 (SO 4 ) 3 ), aluminum chloride (AlCl 3 ) one or more dissolved, the mass fraction is controlled at 30-40%, the temperature is controlled at 20-40°C, and the reaction is stirred for 2 hours;

[0032] b. Obtaining the product according to step a and adding 2 to 5% hydrogen peroxide (27% by mass) and 1 to 5% concentrated sulfuric acid (50% by mass), reacted for 2 to 4 hours. The supernatant is the composite deuranium agent.

Embodiment 2

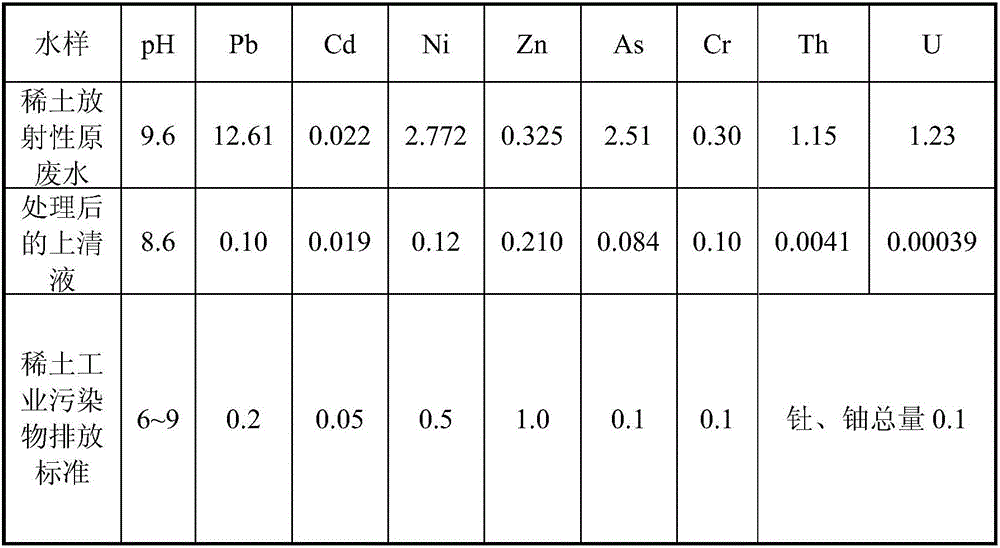

[0034] The radioactive wastewater discharged by a rare earth processing enterprise contains uranium concentration of 3.24mg / L, COD of 445mg / L, and pH value of 10.4. Dilute sulfuric acid is added to the wastewater for pretreatment, and the pH is adjusted to about 3.0, according to 1.2kg / m 3 Add the compound deuranizing agent in an appropriate amount, stir and react for 10 minutes, according to 1.0kg / m 3Add oxidant, oxidize for 20 minutes, then add sodium hydroxide solution to adjust to pH = 9.0, react for 15 minutes, let stand for 10 minutes, take supernatant to analyze and detect uranium, the concentration of uranium in the test water is <0.087mg / L, lower than the discharge limit of 0.1 mg / L for the total amount of thorium and uranium in the "Discharge Standards for Rare Earth Industrial Pollutants" (GB26451-2011).

Embodiment 3

[0036] Take 10L of radioactive wastewater, the concentration of thorium in the wastewater is 0.8mg / L, the concentration of uranium is 2.1mg / L, pH 7.3, COD 322.4mg / L, add 1.0L of compound deuranium agent to the wastewater and react for 10min, then add 10mL of oxidant Carry out oxidation reaction 20min, then add Ca(OH) 2 The solution was adjusted to pH=9.0, and the reaction time was 10 minutes, then 2 mL of flocculant PAM (mass fraction 0.1%) was added, stirred for 1 minute, and left to stand for solid-liquid separation. The supernatant was taken for analysis and detection of thorium and uranium. After analysis and testing, the concentration of thorium in the effluent water is 0.01mg / L, the concentration of uranium is 0.005mg / L, and the total amount of thorium and uranium is 0.015mg / L, which is lower than the "Rare Earth Industrial Pollutant Discharge Standard" (GB26451~2011) Thorium and uranium total discharge limit of 0.1mg / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com