Process for removing thallium through microelectrolysis treatment of thallium-containing heavy metal wastewater

A technology of micro-electrolysis and heavy metals, which is applied in water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effect of high thallium removal efficiency, simple operation, and strong resistance to heavy metal impact loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

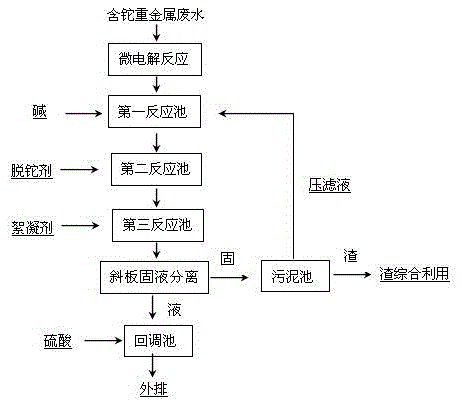

[0020] The invention relates to a process for removing thallium by micro-electrolysis of thallium-containing heavy metal wastewater, which takes thallium-containing heavy metal wastewater as the treatment object, and ensures that thallium and heavy metal elements are discharged up to the standard through micro-electrolysis, neutralization coagulation, and advanced treatment of thallium-removing agents. Including micro-electrolysis part, neutralization coagulation part and sulfuric acid callback part:

[0021] (1) Micro-electrolysis part: The thallium-containing wastewater enters the filler pool evenly through the water distribution device, and the monovalent thallium ions in the wastewater are reduced to thallium simple substances through the reduction of highly active micro-electrolysis fillers and the electrochemical action generated by the micro-battery . Then, through the adsorption of the pores in the highly active micro-electrolytic filler, the simple substance of thalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com