Energy-saving dust removing and intelligent regulation synergetic white smoke removing system and energy-saving dust removing and intelligent regulation synergetic white smoke removing method

A technology for coal-fired power plants and temperature adjustment systems, which is applied in chemical instruments and methods, separation methods, and the use of liquid separation agents, etc. It can solve the problem of large temperature influence on the effect of white mist removal, high operation and maintenance costs, and the effect of white smoke removal. Poor and other problems, to achieve the effect of reducing water loss, reducing energy consumption, and good energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

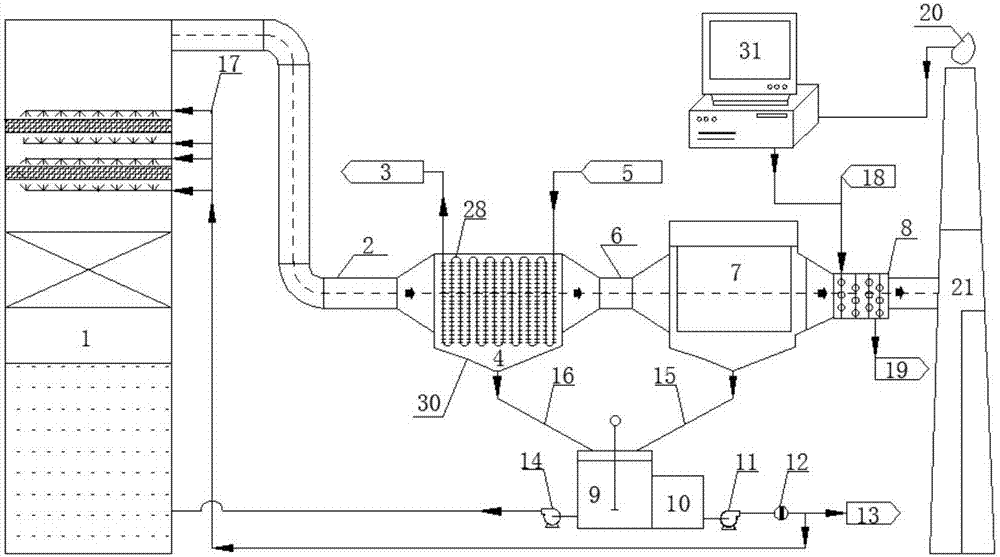

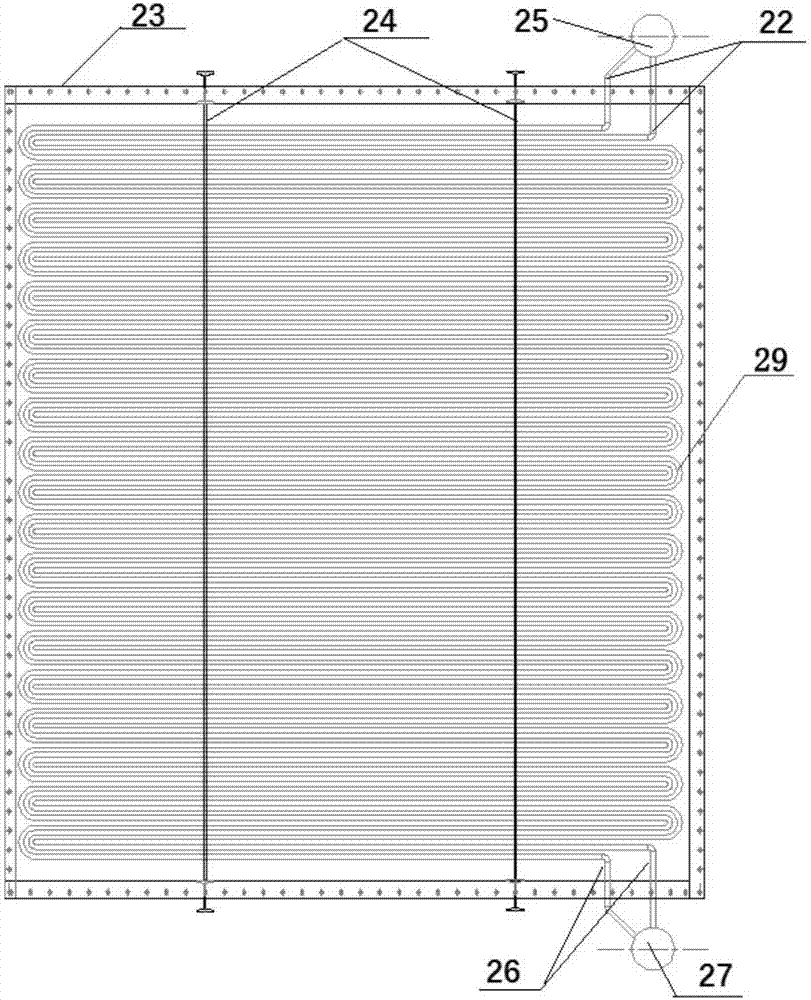

[0035] refer to figure 1 , figure 2 , a coal-fired power plant energy-saving, dust removal and synergistic intelligent regulation and control whitening system, the whitening system includes a desulfurization tower 1, a flue gas phase change coalescer 4, a wet electrostatic multi-extractor 7, and a flue gas heating and whitening device 8 And an intelligent temperature adjustment system 31, the desulfurization tower 1 communicates with the flue gas phase-change coalescer 4 through the outlet flue 2 of the desulfurization tower, and the flue gas phase-change coalescer 4 passes through the outlet flue of the flue gas phase-change coalescer 6 communicates with the wet electrostatic multi-extractor 7, and the wet electrostatic multi-extractor 7 communicates with the flue gas heating and whitening device 8, and the flue gas heating and whitening device 8 communicates with the chimney 21, and the intelligent adjustment The temperature system 31 is connected with the external air mon...

Embodiment 2

[0042] refer to figure 1 , figure 2 , a coal-fired power plant energy-saving dust removal synergistic intelligent regulation and control whitening method, using the whitening system described in embodiment 1, comprising the following steps:

[0043] (1) The saturated wet flue gas processed by the desulfurization tower 1 enters the flue gas phase change condenser 4 through the outlet flue 2 of the desulfurization tower;

[0044] (2) The saturated wet flue gas passes through the flue gas phase change condenser 4, and the industrial water of the power plant is used as a cold source to reduce the temperature of the flue gas by 1 to 3°C. Due to the temperature drop, the saturated wet flue gas forms The condensate film absorbs and adsorbs part of SOx and fine particles in the flue gas, and the condensate enters the drain tank 9 through the condensate collection pipe 16; at the same time, the fine particles and droplets condense and grow near the condensation heat exchange tube 28,...

Embodiment 3

[0050] refer to figure 1 , figure 2 , for a boiler with a capacity of 220t / h, the theoretical flue gas volume at the outlet of desulfurization tower 1 is 300,000Nm 3 / h, the temperature of the saturated wet flue gas is 53°C, the saturated wet flue gas treated by the desulfurization tower 1 enters the flue gas phase change condenser 4 through the outlet flue 2 of the desulfurization tower; the saturated wet flue gas passes through the flue gas phase The variable condenser 4 uses the industrial water of the power plant as a cold source to reduce the temperature of the flue gas by 2°C. Due to the temperature drop of the saturated wet flue gas, the condensate film formed on the surface of the condensation heat exchange tube 28 absorbs and adsorbs part of SOx and Fine particles and condensate enter the drainage tank 9 through the condensate collection pipe 16; meanwhile, the fine particles and droplets condense and grow near the condensation heat exchange tube 28, and the wet ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com