Method for abstracting chromium and nickel salt for stainless steel acid-washing wastewater

A technology of pickling wastewater and extraction methods, which is applied to chemical instruments and methods, nickel compounds, chromium compounds, etc., can solve the problems of large dosage of chemicals, high economic costs, secondary pollution, etc., and achieve convenient control, good economic benefits, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

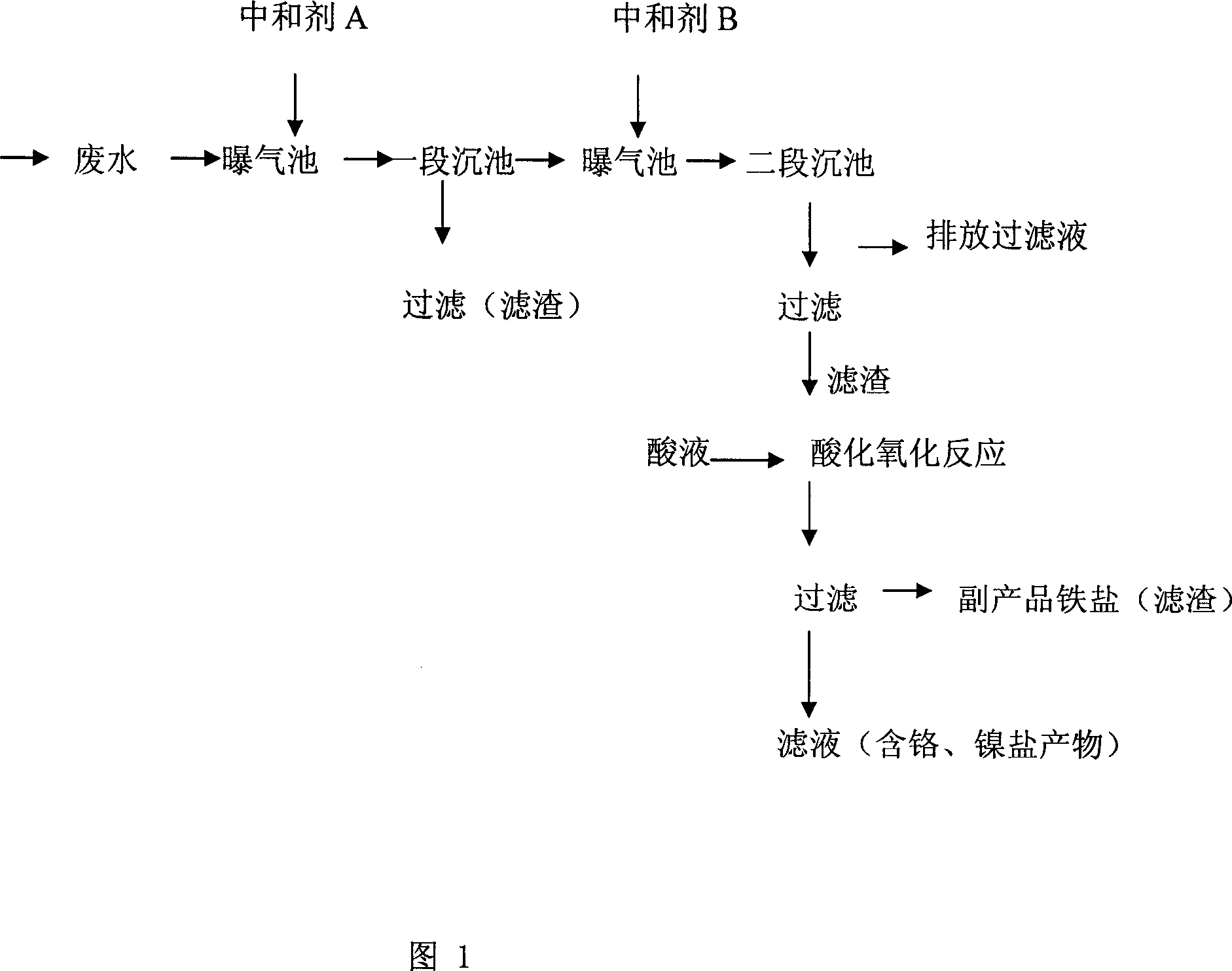

Embodiment 1

[0023] Embodiment 1: According to the implementation process shown in the accompanying drawings, 1 liter of production wastewater from a stainless steel company was taken, and the measured concentration of chromium and nickel was 120 mg / L. Then add 3 grams of milk of lime, stir evenly, the measured pH is 3.8, filter after standing, remove the solid matter, add 2 grams of soda ash to the filtrate, and measure the pH to be 7.8, then filter, the filtrate can be discharged, and then go to the solid Add sulfuric acid to the filter residue, adjust the pH to 1.8, filter again, and remove the solid matter. The main component is iron salt, and the filtrate is a solution containing chromium and nickel salt. The measured content is 9 g / L of chromium and 10.8 g / L of nickel.

Embodiment 2

[0024] Embodiment 2: By the same method as in Embodiment 1, 1 liter of production wastewater from a stainless steel company was obtained, and it was measured that the concentration of chromium and nickel was 130 mg / L. Then add 3.2 grams of milk of lime, stir evenly, the measured pH is 3.0, filter after standing, remove the solid matter, add 2.3 grams of soda ash to the filtrate, and measure the pH to be 7.3, then filter, the filtrate can be discharged, and then go to the solid Add hydrochloric acid to the filter residue, adjust the pH to 1.5, filter again, and remove the solid matter, which contains iron salt as the main component. The filtrate is a solution containing chromium and nickel salt, and the measured content of chromium is 9.4 g / L and nickel is 12.1 g / L.

Embodiment 3

[0025] Embodiment three: by the same method of embodiment one, take 1 liter of production waste water from certain stainless steel company, process, draw list (measure by implementation steps).

[0026] Preface

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com