Low-shrinkage polypropylene composition and preparation method thereof

A technology of polypropylene composition and low shrinkage, which is applied in the field of modified polypropylene composition and its preparation, low shrinkage polypropylene composition and its preparation, and can solve the problem of high cost of modification, high addition amount, etc. problems, to achieve excellent balance between rigidity and toughness, easy operation and low cost

Active Publication Date: 2013-03-06

CHINA PETROLEUM & CHEM CORP

View PDF4 Cites 34 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since the market price of Hifax7271A is more than 10,000 yuan per ton higher than that of polypropylene in the same period, and the relative addition amount is relatively high, it needs to be used in conjunction with other elastomer POE, so the modification cost of this type of material is relatively high

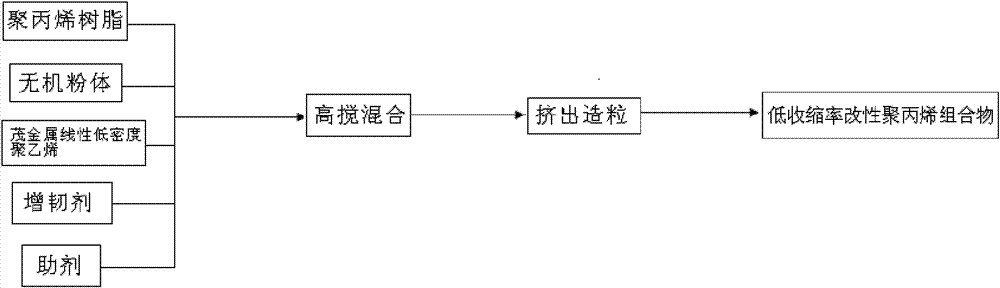

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

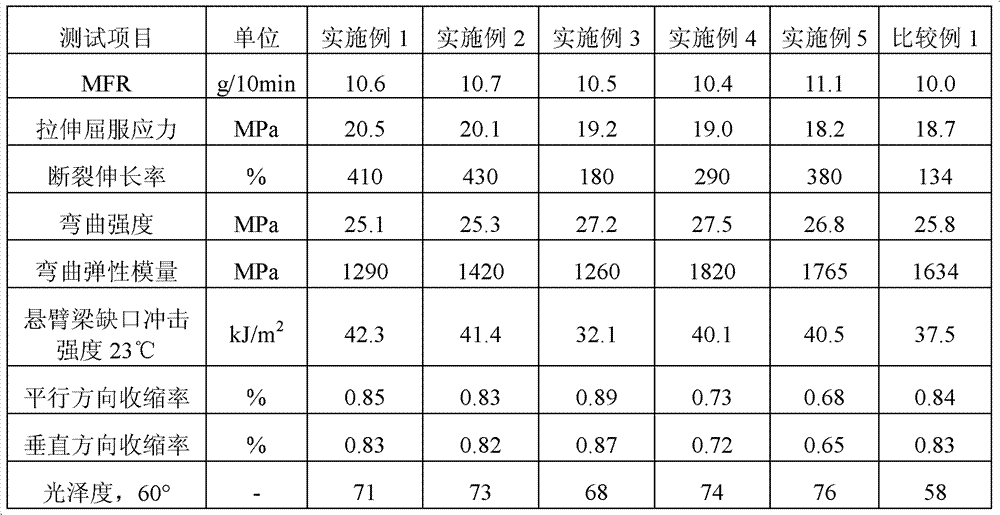

Embodiment 1~5

[0029] The formulations of the components of Examples 1-5 are shown in Table 1, the performance indicators are shown in Table 2, and the raw material grades and performance parameters are shown in Table 5.

Embodiment 6~10

[0031] The formulations of the components of Examples 6-10 are shown in Table 3, the performance indicators are shown in Table 4, and the raw material grades and performance parameters are shown in Table 5.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Login to View More

Abstract

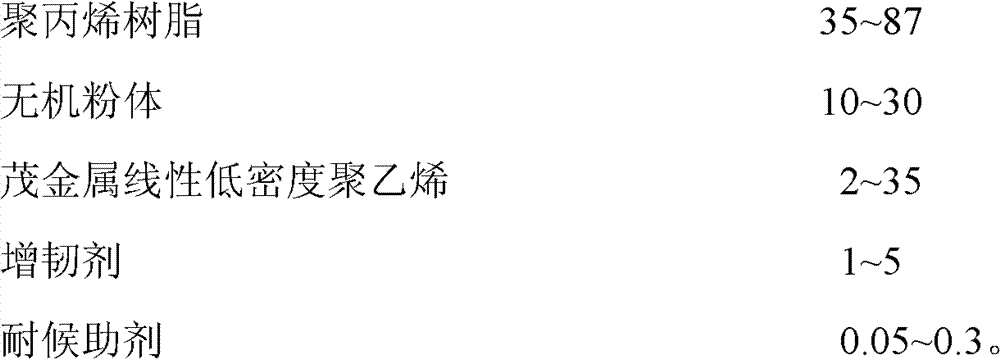

The invention relates to a low-shrinkage polypropylene composition and a preparation method thereof, belonging to the technical field of high polymer materials. The low-shrinkage polypropylene composition is prepared from the following raw materials in parts by mass: 35-87 parts of polypropylene resin, 10-30 parts of inorganic powder, 2-35 parts of metallocene linear low-density polyethylene, 1-5 parts of toughener and 0.05-0.3 part of weather-resistant assistant. According to the invention, the modified polypropylene composition having a low shrinkage is prepared by taking impact polypropylene copolymer as a base resin, adding the inorganic powder, the metallocene linear low-density polyethylene and the toughener and extruding and granulating with a double-screw extruder; the prepared polypropylene composition has low cost, low shrinkage, excellent rigidity-toughness balance, high glossiness and favorable processing flowability; and the preparation method is simple and easy to implement and easy to operate.

Description

technical field [0001] The invention relates to a low-shrinkage polypropylene composition and a preparation method thereof, in particular to a low-shrinkage modified polypropylene composition and a preparation method of the composition, and belongs to the technical field of polymer materials. Background technique [0002] Polypropylene (PP) is one of the most widely used varieties among the five synthetic resins. It has the characteristics of low density, good mechanical properties, good chemical resistance and insulation, non-toxic during processing, and easy recycling. It has been widely used in Automobiles, home appliances, packaging, daily necessities, chemicals, construction, and chemical fibers, etc., but PP also has disadvantages such as poor low-temperature toughness and large molding shrinkage. In the fields of automobiles and household appliances, polypropylene is used after modification. With the enrichment of polypropylene resin varieties and the improvement of p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/16C08L23/08C08K13/02C08K3/34C08K3/26C08K5/3475B29B9/06

Inventor 李延亮唐岩李丽王秀丽许平黄峰

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com