Preparation method of graphene nonwoven fabric

A non-woven fabric, graphene technology, applied in the field of graphene non-woven fabric preparation, can solve the problems of low skin dryness, low bacteriostatic ability, skin rash, etc. Integrity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

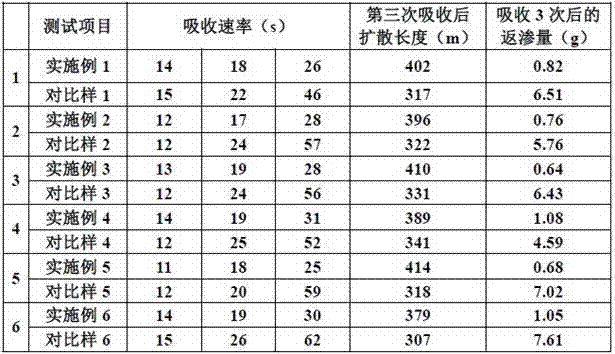

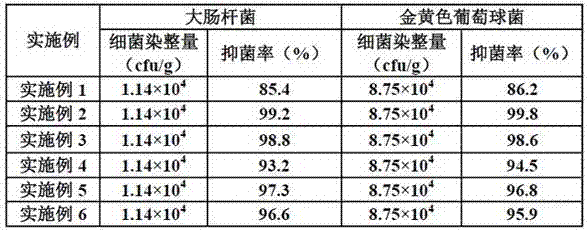

Examples

Embodiment 1

[0042] In this embodiment, 10 parts of porous graphene oxide, 47 parts of acrylate, 0.045 parts of potassium persulfate, 0.90 parts of N,N'-methylenebisacrylamide, 0.05 parts of sodium lauryl sulfate, azodimethoxane 0.9 parts of amide, spunbond nonwoven fabric treated with hydrophilic finishing, the square gram weight is 20g / m 2 .

[0043] Present embodiment prepares graphene non-woven fabric according to the following steps:

[0044] Step 1: Prepare the acrylate with deionized water into a solution with a concentration of 30%-45%, add sodium lauryl sulfate and azodicarbonamide and stir for 5-30min.

[0045] Step 2: Add porous graphene oxide to the solution in step 1, and use ultrasonic dispersion for 30-60 minutes to obtain graphene suspension mixture A.

[0046] Step 3: Heat up the graphene suspension mixture in step 2 to 42-85°C, then add N,N'-methylenebisacrylamide, and disperse it uniformly by ultrasonic for 3-30min to form graphene suspension mixture B;

[0047] Step ...

Embodiment 2

[0057] In this example, 50 parts of porous reduced graphene, 10 parts of acrylic acid, 0.001 part of potassium persulfate, 0.30 part of N,N'-methylenebisacrylamide, 0.2 part of sodium lauryl sulfate, azodicarbonamide 0.2 parts, hot-rolled nonwoven fabric with hydrophilic finishing treatment, the square gram weight is 18g / m 2 .

[0058] Form the graphene coating on the surface layer of the non-woven fabric for the absorbent core wrapping layer obtained by the preparation method of Example 1, and the graphene coating includes a three-dimensional network-like cross-linked structure porous polymer. The structural porous polymer is uniformly dispersed and loaded with graphene, and the cross-linked structural porous polymer has through holes that penetrate each other and penetrate to the non-woven fabric substrate, and the pore size of the through holes is 50-2000 microns , so that this embodiment has the absorption effect of rapidly penetrating liquid downward.

[0059] This embo...

Embodiment 3

[0061] In this example, 30 parts of porous graphene oxide, 35 parts of methyl acrylate, 0.035 parts of potassium persulfate, 0.70 parts of N,N'-methylenebisacrylamide, 0.2 parts of sodium lauryl sulfate, azobis 0.2 parts of formamide, 0.5 parts of azobisisobutyronitrile, hot-rolled non-woven fabrics treated with hydrophilic finishing, the square gram weight is 20g / m 2 .

[0062] Form the graphene coating on the surface layer of the non-woven fabric for the absorbent core wrapping layer obtained by the preparation method of Example 1, and the graphene coating includes a three-dimensional network-like cross-linked structure porous polymer. The structural porous polymer is uniformly dispersed and loaded with graphene, and the cross-linked structural porous polymer has through holes that penetrate each other and penetrate to the non-woven fabric substrate, and the pore size of the through holes is 50-2000 microns , so that this embodiment has the absorption effect of rapidly pene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com