MnO2/PPS composite material and preparation method and application thereof

A composite material and fabric technology, applied in the field of MnO2/PPS composite material and its preparation, can solve the problems of high load, inability to fully reflect catalyst performance, poor catalyst dispersion, etc., and achieve low load and high NOx removal efficiency , evenly dispersed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

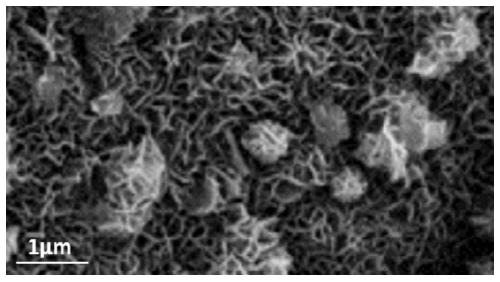

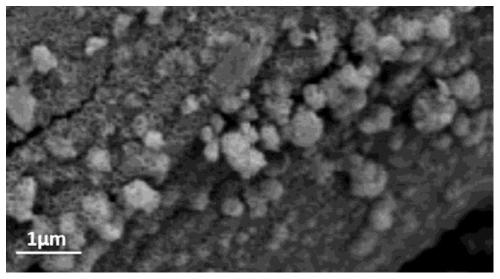

[0036] This embodiment discloses a kind of MnO 2 The preparation method of the PPS dust removal and denitrification integrated composite filter material comprises the following steps:

[0037] (1) Wash the PPS filter material with a diameter of 1cm and immerse it in the mixed solution of sodium lauryl sulfate of 0.6g / L and 0.06mol / L of nitric acid, the solvent is water, the distance between the PPS filter material and the mixed solution The bath ratio is 1:5, ultrasonic for 5 minutes, and the frequency of ultrasonic is 30kHz, so that it can fully absorb the H in the solution + , taken out to obtain a PPS filter material with a layer of charge on the surface;

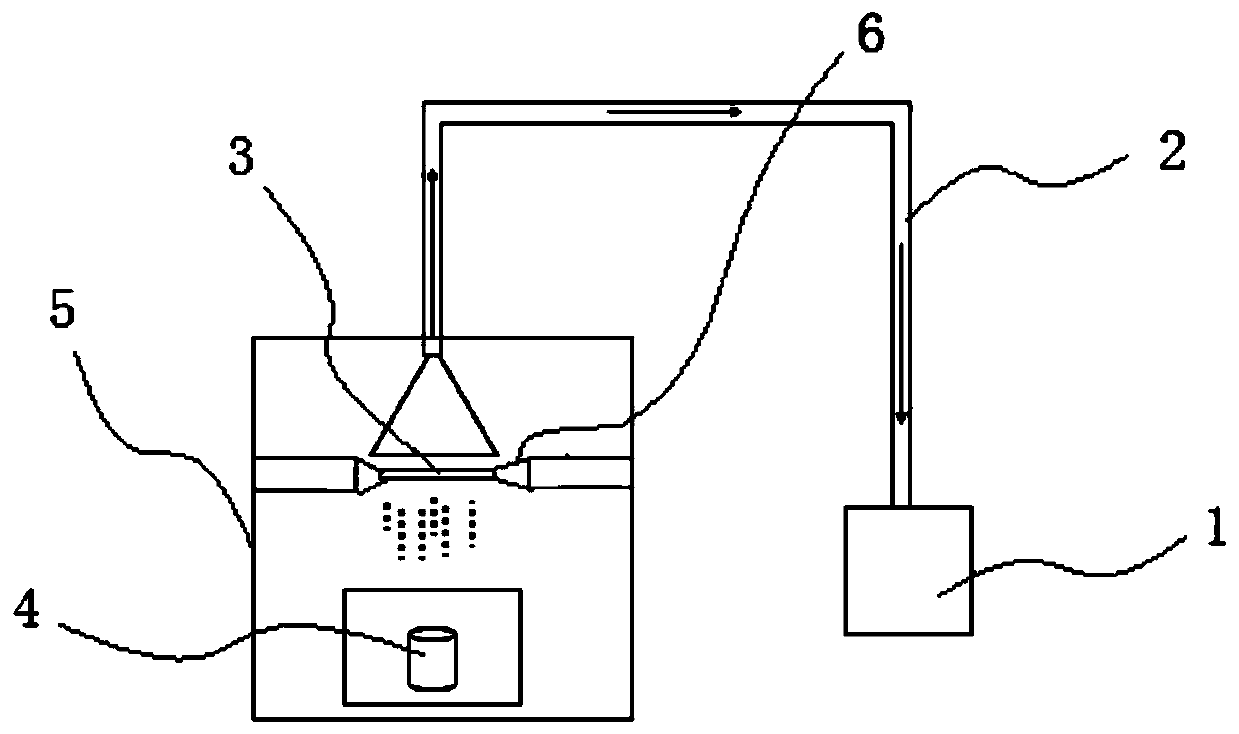

[0038] (2) Take 0.086g of potassium permanganate and dissolve it in 20mL of water to obtain a potassium permanganate solution; heat it in a water bath to 70°C, and then add it into an ultrasonic atomizer to obtain a layer of charge on the surface obtained in step (1). The PPS filter material is fixed directly above the m...

Embodiment 2

[0042] This embodiment discloses a kind of MnO 2 The preparation method of the PPS dust removal and denitrification integrated composite filter material comprises the following steps:

[0043] (1) Wash the PPS filter material with a diameter of 1cm and immerse it in the mixed solution of 0.6g / L sodium lauryl sulfate and 0.3mol / L nitric acid, the solvent is water, and the distance between the PPS filter material and the mixed solution The bath ratio is 1:5, ultrasonic for 5 minutes, and the frequency of ultrasonic is 30kHz, so that it can fully absorb the H in the solution + , taken out to obtain a PPS filter material with a layer of charge on the surface;

[0044] (2) Dissolve 0.086g of potassium permanganate in 5mL of water, heat it in a water bath to 70°C, then add it to an ultrasonic atomizer, and fix the PPS filter material with a layer of charge on the surface obtained in step (1) on an ultrasonic Just above the mist outlet of the atomizer, then place the ultrasonic ato...

Embodiment 3

[0048] This embodiment discloses a kind of MnO 2 The preparation method of the PPS dust removal and denitrification integrated composite filter material comprises the following steps:

[0049] (1) Wash the PPS filter material with a diameter of 1cm and immerse it in the mixed solution of sodium lauryl sulfate of 0.6g / L and 0.18mol / L of nitric acid, the solvent is water, the distance between the PPS filter material and the mixed solution The bath ratio is 1:5, ultrasonic for 5 minutes, and the frequency of ultrasonic is 30kHz, so that it can fully absorb the H in the solution + , taken out to obtain a PPS filter material with a layer of charge on the surface;

[0050] (2) Dissolve 0.086g of potassium permanganate in 15mL of water, heat it in a water bath to 70°C, then add it into an ultrasonic atomizer, and fix the PPS filter material with a layer of charge on the surface obtained in step (1) on the ultrasonic atomizer Just above the mist outlet of the nebulizer, then place t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com