Desulfurized gypsum storage device

A storage device and desulfurization gypsum technology, applied in packaging, packaged food, biological packaging, etc., can solve problems such as frost return, soil pollution, and impurities mixed in, and achieve the effects of increasing service life, ensuring integrity, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

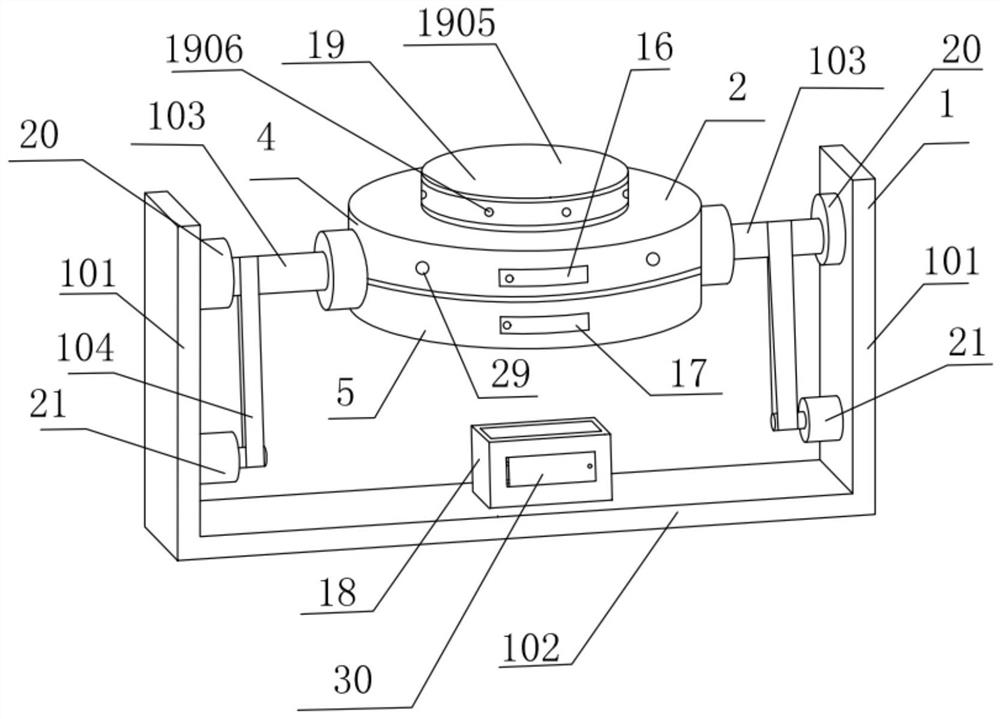

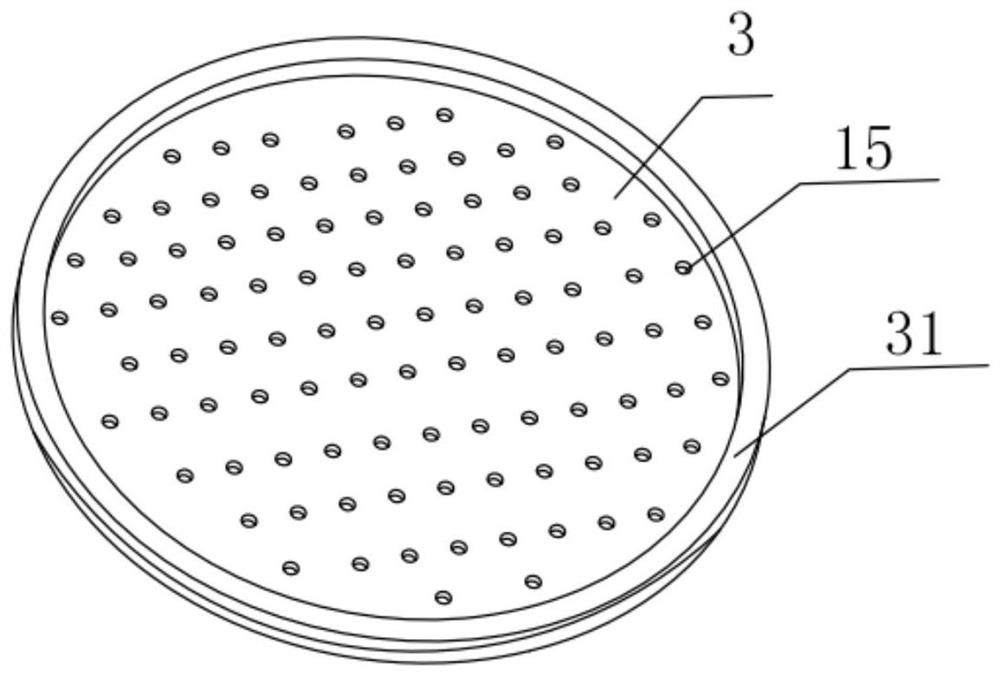

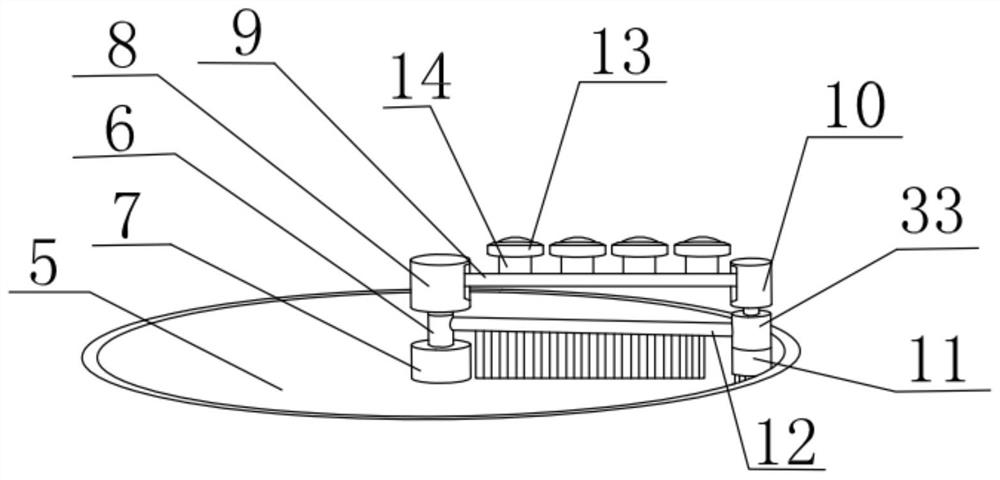

[0025] like Figure 1-9The shown storage device for desulfurization gypsum includes a support 1, on which is arranged a silo 2 that can rotate along the transverse axis direction, the silo 2 is cylindrical and has a cavity structure inside, and the transverse axis is connected to the silo. The bottom surface is parallel, the storage bin 2 is divided into two closed cavities up and down by the elastic soft plate 3, the upper layer is the storage chamber 4, the lower layer is the filter chamber 5, and the bottom surface of the filter chamber 5 is provided with a first motor 7, the first motor 7. The output shaft is connected to the first hydraulic cylinder 6. The end of the telescopic rod of the first hydraulic cylinder 6 is connected to the first rotating rod 9 through the first fixing member 8. The length direction of the first rotating rod 9 is parallel to the bottom surface of the filter cavity 5. The rod 9 is also connected to the second fixing member 10, the lower end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com