Preparation method of supermolecule gel-based composite phase change material

A technology of composite phase change materials and supramolecular gels, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of poor compatibility between phase change substrates and phase change core materials, and facilitate large-scale production, Solve the problem of leakage, the effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0026] (1) Weigh 2mmol of chromium nitrate and 2mmol of trimesic acid into a 50mL beaker, add 20mL of ethanol to it, stir until completely dissolved, cover the surface of the beaker with a parafilm, and place at 80°C React in an oven for 4 hours, remove the parafilm on the beaker, and dry the beaker in a vacuum oven at 40°C for 24 hours to obtain a Cr-BTC-Gel supramolecular gel substrate.

[0027] (2) Add 0.9 g of octadecanoic acid (SA) to 50 mL of ethanol solvent, place it in an oil bath at 70°C, and stir thoroughly for 2.5 hours until the octadecanoic acid is completely dissolved. After obtaining a clear solution, add 0.1 g The Cr-BTC-Gel supramolecular gel base material prepared in the above step (1) was reacted in an oil bath at 70°C for 6h, and then transferred to an oven at 60°C for drying for 24h to obtain the SACr-BTC-Gel composite phase change material.

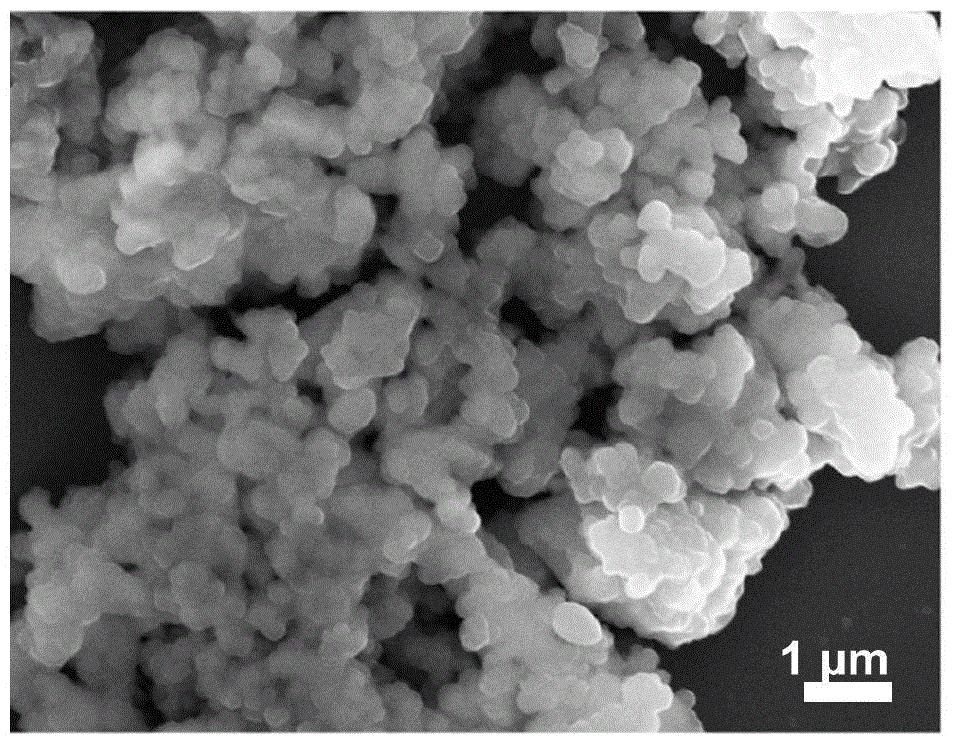

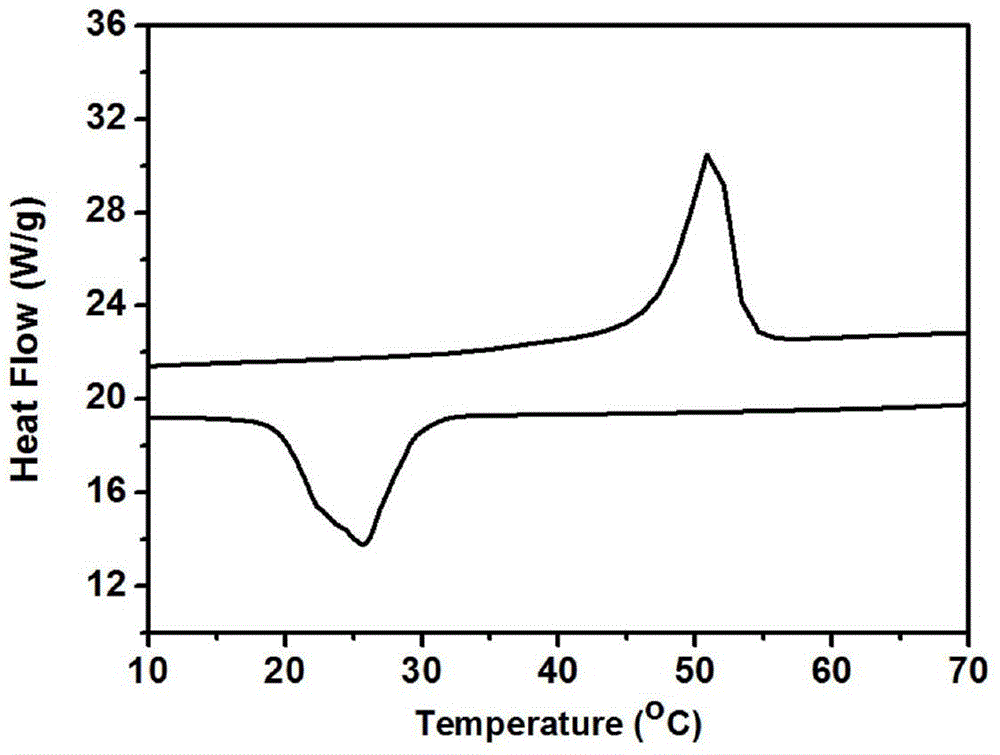

[0028] The prepared SACr-BTC-Gel composite phase change material was characterized by scanning electron microscop...

Embodiment example 2

[0030] (1) Weigh 2mmol of chromium nitrate and 2mmol of terephthalic acid into a 50mL beaker, add 20mL of ethanol into it, stir well until completely dissolved, cover the surface of the beaker with a sealing film, and place at 80°C React in an oven for 4 hours, remove the parafilm on the beaker, and dry the beaker in a vacuum oven at 40°C for 24 hours to obtain a Cr-BDC-Gel supramolecular gel substrate.

[0031] (2) Add 0.5g of PEG-2000 to 50mL of ethanol solvent, place it in an oil bath at 70°C, and stir thoroughly for 2.5h until PEG-2000 is completely dissolved. After obtaining a clear solution, add 0.1g of the above-mentioned step The Cr-BDC-Gel supramolecular gel substrate prepared in (1) was reacted in an oil bath at 70°C for 6h, and then transferred to an oven at 60°C for 24h to obtain a PEG-2000Cr-BDC-Gel composite phase change material.

Embodiment example 3

[0033] (1) Weigh 1.2mmol of ferric nitrate and 2mmol of 5-aminoisophthalic acid in a 50mL beaker, add 12mL of ethanol and 8mL of N,N-dimethylformamide (DMF), and stir thoroughly After completely dissolving, cover the surface of the beaker with a parafilm, place it in an oven at 90°C for 12 hours, remove the parafilm on the beaker, and dry the beaker in a vacuum oven at 40°C for 24 hours to obtain Fe - ADC-Gel supramolecular gel substrate.

[0034] (2) Add 0.045g of stearic acid into 40mL of ethanol solvent, place it in an oil bath at 80°C, stir fully for 4h until the stearic acid is completely dissolved, and after obtaining a clear solution, add 0.1g of the above step ( The Fe-ADC-Gel supramolecular gel substrate prepared in 1) was reacted in an oil bath at 80°C for 6h, and then transferred to an oven at 60°C for drying for 24h to obtain a stearic acid Fe-ADC-Gel composite phase change material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| latent heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com