Immobilized rhodium-based catalyst as well as preparation method and application thereof

A catalyst, rhodium-based technology, applied in catalytic olefin hydroformylation reaction, immobilized rhodium-based catalyst and its preparation field, can solve the problem of low catalytic activity and selectivity, swelling effect, low specific surface area, etc. problems, to achieve the effect of simple preparation method, easy recovery and high product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

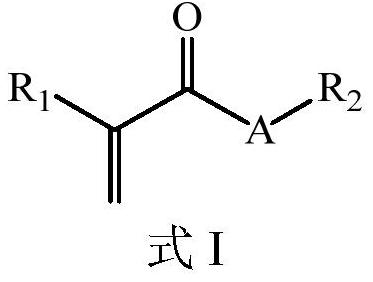

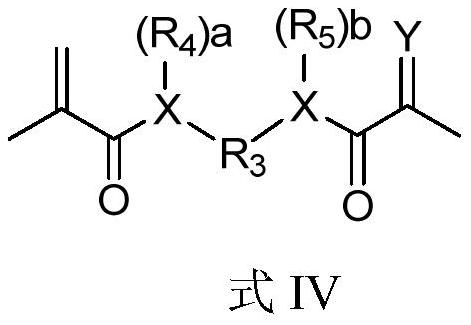

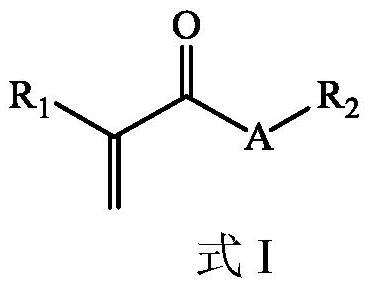

[0052] This example is used to illustrate the preparation process of microgel-supported rhodium-based catalyst Rh@G1.

[0053] In a 50mL three-necked flask, add 10mL of toluene, then add 87mg of diphenyl p-styrylphosphine and 15mg of rhodium dicarbonyl acetylacetonate to the toluene, blow the resulting solution with nitrogen for 30 minutes, then add 1.28mL of methyl methacrylate , 30mg of benzoyl peroxide and 237mg of ethylene glycol dimethacrylate, the temperature was raised to 80°C and the reaction was continued for 12 hours. After cooling, the reaction solution was poured into methanol, and a black precipitate was precipitated, which was filtered to obtain the microgel-immobilized rhodium-based catalyst Rh@G1.

Embodiment 2

[0055] This example is used to illustrate the preparation process of microgel-immobilized rhodium-based catalyst Rh@G2.

[0056] In a 50mL three-neck flask, add 10mL toluene, then add 87mg diphenyl p-styryl phosphine and 15mg rhodium dicarbonyl acetylacetonate to the toluene, blow the resulting solution with nitrogen for 30 minutes, then add 1.23mL N,N'- Dimethacrylamide, 30mg of benzoyl peroxide and 184mg of N,N'-methylenebisacrylamide were heated to 80°C and continued to react for 12 hours. After cooling, the reaction solution was poured into methanol, and a black precipitate was precipitated, which was filtered to obtain a microgel-immobilized rhodium-based catalyst Rh@G2.

Embodiment 3

[0058] This example is used to illustrate the preparation process of microgel-immobilized rhodium-based catalyst Rh@G3.

[0059] In a 50mL three-neck flask, add 10mL toluene, then add 87mg diphenyl p-styryl phosphine and 15mg rhodium dicarbonyl acetylacetonate to the toluene, blow the resulting solution with nitrogen for 30 minutes, then add 1.23mL N,N'- Dimethacrylamide, 30mg of benzoyl peroxide and 92mg of N,N'-methylenebisacrylamide were heated to 80°C and continued to react for 12 hours. After cooling, the reaction solution was poured into methanol, and a black precipitate was precipitated, which was filtered to obtain the microgel-immobilized rhodium-based catalyst Rh@G3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com