Closed boron group composite nano noble metal catalyst as well as preparation method and application thereof

A noble metal catalyst and noble metal technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, oxidation reaction preparation, chemical instruments and methods, etc. Uniformity and other issues, to achieve the effects of cost controllable, high reuse rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

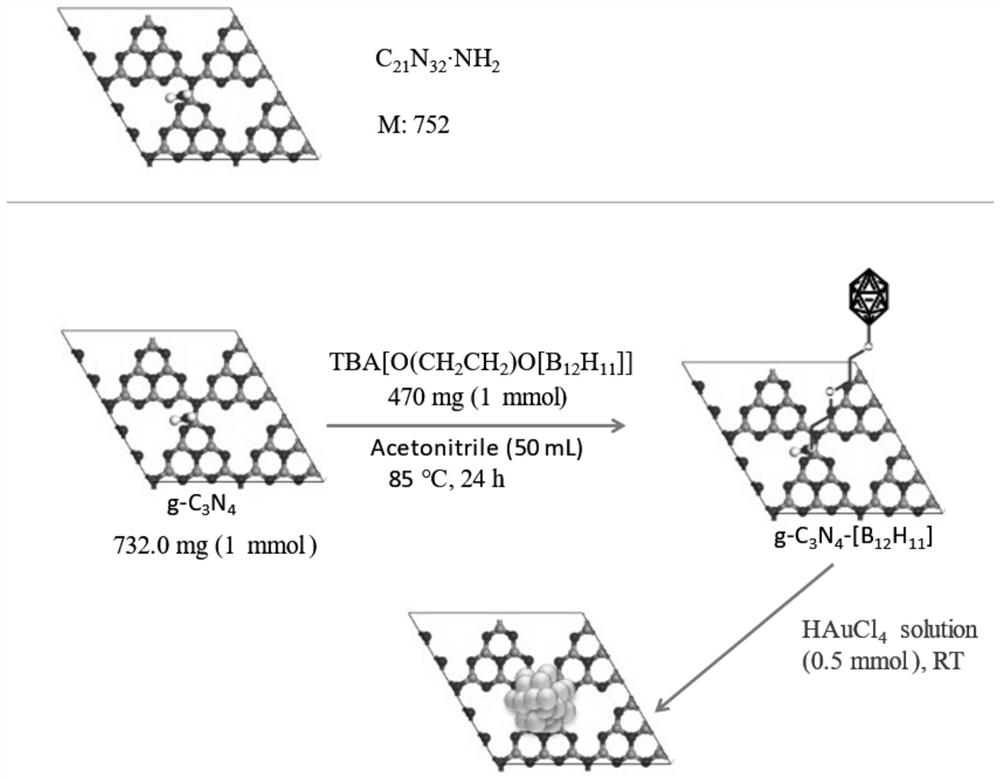

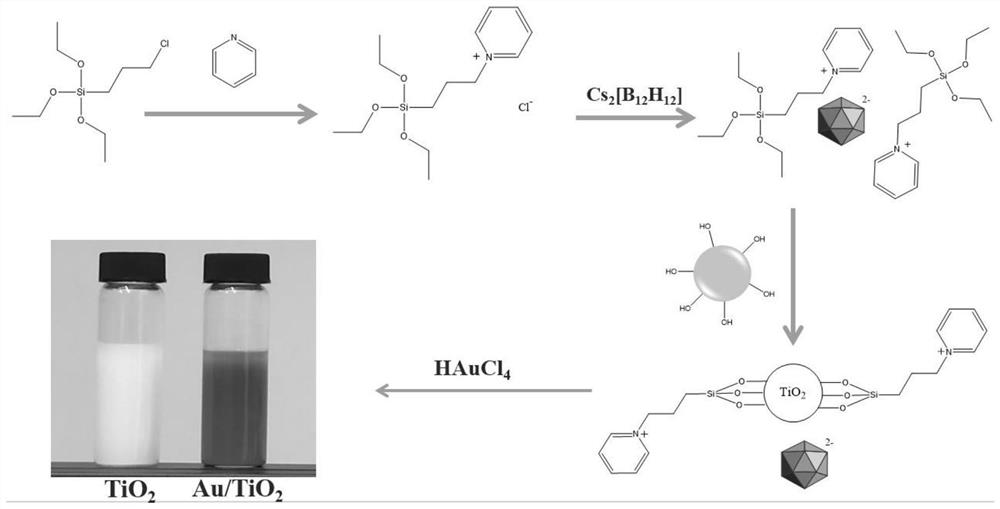

[0043] Preparation of catalyst, synthetic route as attached figure 1 As shown, the steps are as follows:

[0044] (1) 1.0236g g-C 3 N 4 Disperse in 50ml water, add 0.3543g K 2 B 12 h 12 , continuously stirring and reacting at 80°C for 24h;

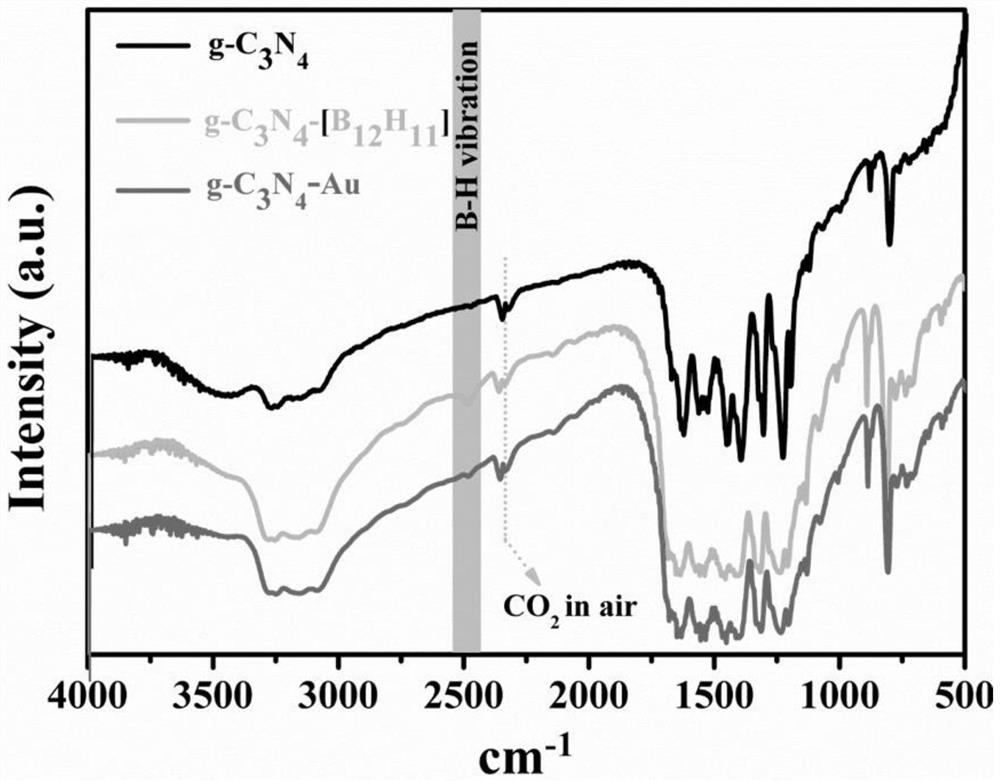

[0045] (2) Filter after 24 hours, wash the filter cake 6 times with water and ethanol successively, and place the washed precipitate at room temperature for 12 hours in vacuum to obtain 1.1024 g of g-C 3 N 4 Base K 2 B 12 h 12 , the material was characterized by Fourier transform infrared spectroscopy (FT-IR) ( figure 2 shown), prove that g-C 3 N 4 Successfully combined with boron clusters;

[0046] (3) 1.0978g g-C 3 N 4 Base K 2 B 12 h 12 Disperse in 20ml of water; quickly add 0.0364g of sodium chloroaurate with a purity of 99%;

[0047] (4) After reacting at 20°C for 10 minutes under a 365nm ultraviolet lamp, filter to obtain a purple precipitate;

[0048] (5) After the precipitate was filtered, the precipitate was w...

Embodiment 2

[0052] Preparation of catalyst, the steps are as follows:

[0053] (1) 1.0246g g-C 3 N 4 Disperse in 50ml water, add 0.6884g Na 2 B 12 h 12 , continuously stirring and reacting at 60°C for 24h;

[0054] (2) Filter after 24 hours, wash the filter cake 6 times with water and ethanol successively, and place the washed precipitate at room temperature for 18 hours in vacuum to obtain 1.3145 g g-C 3 N 4 Base Na 2 B 12 h 12 ;

[0055] (3) 1.3124g g-C 3 N 4 Base Na 2 B 12 h 12 Disperse in 20ml of water; quickly add 0.0517g of sodium chloroaurate with a purity of 99%;

[0056] (4) After stirring and reacting at 40°C for 20 minutes under a 365nm ultraviolet lamp, filter to obtain a purple precipitate;

[0057] (5) After the precipitate was filtered, the precipitate was washed four times with water and ethanol in turn, and the washed precipitate was vacuum-dried at room temperature for 12 hours to obtain 1.3247 g g-C 3 N 4 Base Na 2 B 12 h 12 Nano gold catalyst;

[...

Embodiment 3

[0062] (1) 0.9956g g-C 3 N 4 Disperse in 50ml water, add 1.0765g Cs 2 B 6 h 6 , continuously stirring and reacting at 75°C for 72h;

[0063] (2) Filter after 72h, wash the filter cake 8 times with water and ethanol in turn, and place the washed precipitate at room temperature for 24h in vacuum to obtain 2.0043g g-C 3 N 4 Base Cs 2 B 6 h 6 , the material is characterized by Fourier transform infrared spectroscopy (FT-IR);

[0064] (3) 1.9475g g-C 3 N 4 Base Cs 2 B 6 h 6 Disperse in 20ml of water; quickly add 0.0682g of sodium chloropalladate with a purity of 99%;

[0065] (4) After stirring and reacting at 50°C for 30 minutes under a 365nm ultraviolet lamp, filter to obtain a black precipitate;

[0066] (5) After the precipitate was filtered, the precipitate was washed 8 times with water and ethanol in turn, and the washed precipitate was vacuum-dried at room temperature for 24 hours to obtain 2.2128g g-C 3 N 4 Base Cs 2 B 6 h 6 Nano palladium catalyst.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com