Molecular sieve confinement metal oxide catalyst, and preparation method and application of molecular sieve confinement metal oxide catalyst in catalytic synthesis of pentamethylene diamine

A molecular sieve and catalyst technology, which is applied in the field of molecular sieve-confined metal oxide catalysts and preparation, can solve the problem of low selectivity of pentamethylenediamine, achieve the effects of reducing production costs, maintaining a good catalyst structure, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation method of the molecular sieve confined metal oxide catalyst in this embodiment is as follows:

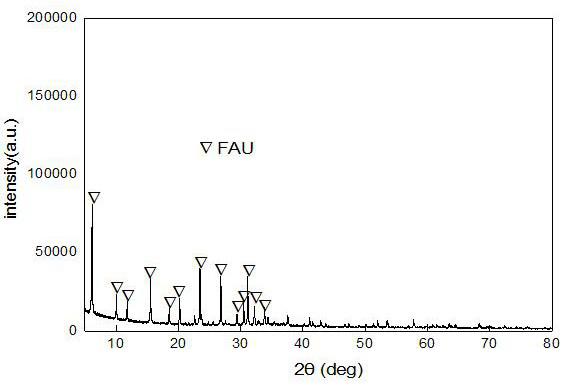

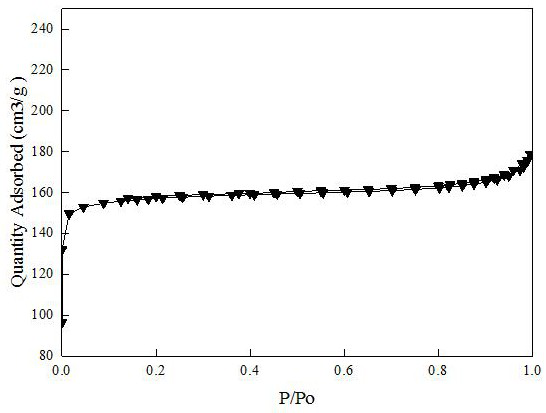

[0024] The Ru@FAU-1 catalyst was prepared by combining in-situ synthesis and static synthesis. The specific preparation steps were as follows: dissolve 5.6 g of sodium hydroxide in 50 ml of deionized water, stir vigorously until completely dissolved, and then add 0.675 g of metaaluminic acid Sodium, after the mixed solution is stirred evenly, add 25.38 g of silica sol (silica containing 25%), then add 0.665 g of ruthenium trichloride, stir the resulting mixed solution at room temperature for 4 hours, then transfer it to a stainless steel reaction kettle, and place it in a 100 °C oven Medium crystallization for 12 h. After the reaction was completed, the reactor was cooled to room temperature, the suspension was poured into a centrifuge tube, centrifuged, washed with deionized water until the pH was equal to 7, and dried in an oven at 80°C overnight to prepare ...

Embodiment 2

[0029] The preparation method of the molecular sieve confined metal oxide catalyst in this embodiment is as follows:

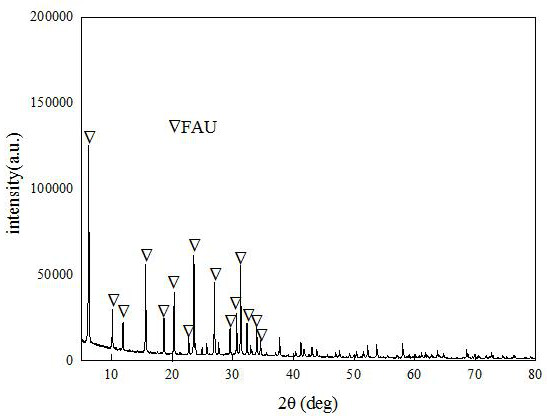

[0030] The 5% Ru@FAU-2 catalyst was prepared by combining in-situ synthesis and static synthesis. The specific preparation steps were as follows: dissolve 5.6 g of sodium hydroxide in 50 ml of deionized water, stir vigorously until completely dissolved, and then add 0.675 g Sodium metaaluminate, after the mixed solution is stirred evenly, add 4.23 g of silica sol (silicon dioxide contains 25%), then add 0.342 g of ruthenium trichloride, and the resulting mixed solution is stirred at room temperature for 4 hours and then transferred to a stainless steel reactor. Crystallized in an oven at 100 °C for 12 h. After the reaction was completed, the reactor was cooled to room temperature, the suspension was poured into a centrifuge tube, centrifuged, washed with deionized water until the pH was equal to 7, and then dried in an oven at 80°C overnight to obtain 5% Ru@FA...

Embodiment 3

[0035] The preparation method of the molecular sieve confined metal oxide catalyst in this embodiment is as follows:

[0036] The method of combining in-situ synthesis and static synthesis was adopted, and Ru@FAU-3 catalyst was prepared by dealumination with citric acid. The specific preparation steps were as follows: 5.6 g of sodium hydroxide was dissolved in 50 ml of deionized water, stirred vigorously until completely dissolved, Then add 0.675g sodium metaaluminate to it, add 25.38g silica sol (silicon dioxide contains 25%) after the mixed solution is stirred evenly, then add 0.665g ruthenium trichloride, stir the gained mixed solution at room temperature for 4 hours, then transfer to In a stainless steel reactor, crystallize in an oven at 100 °C for 12 h. After the reaction was completed, the reactor was cooled to room temperature, the suspension was poured into a centrifuge tube, centrifuged, washed with deionized water until the pH was equal to 7, dried in an oven at 80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com