Single Use Logistic Glider

a logistic and glider technology, applied in the direction of gliders, emergency equipment, spars/stringers, etc., can solve the problems of valuable and limited assets being subjected to enemy fire, and achieve the effect of low cost, rugged and smooth surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

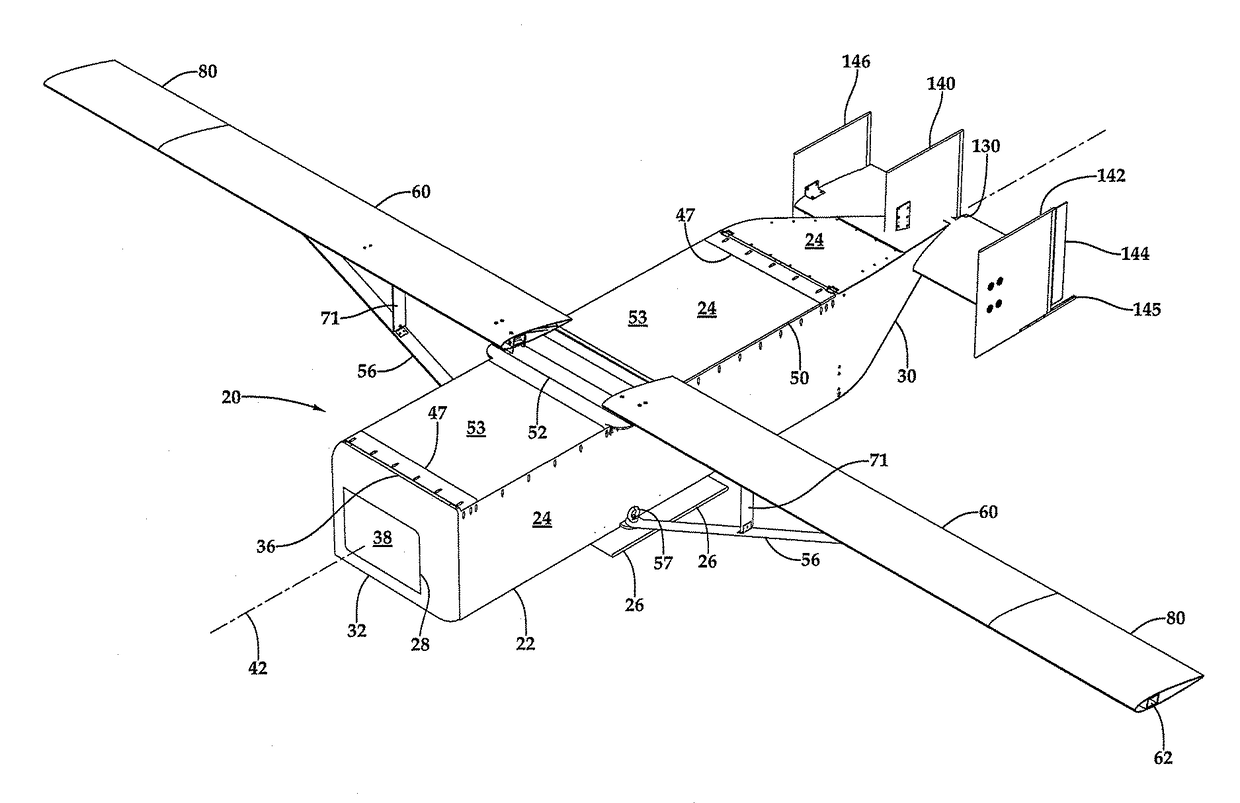

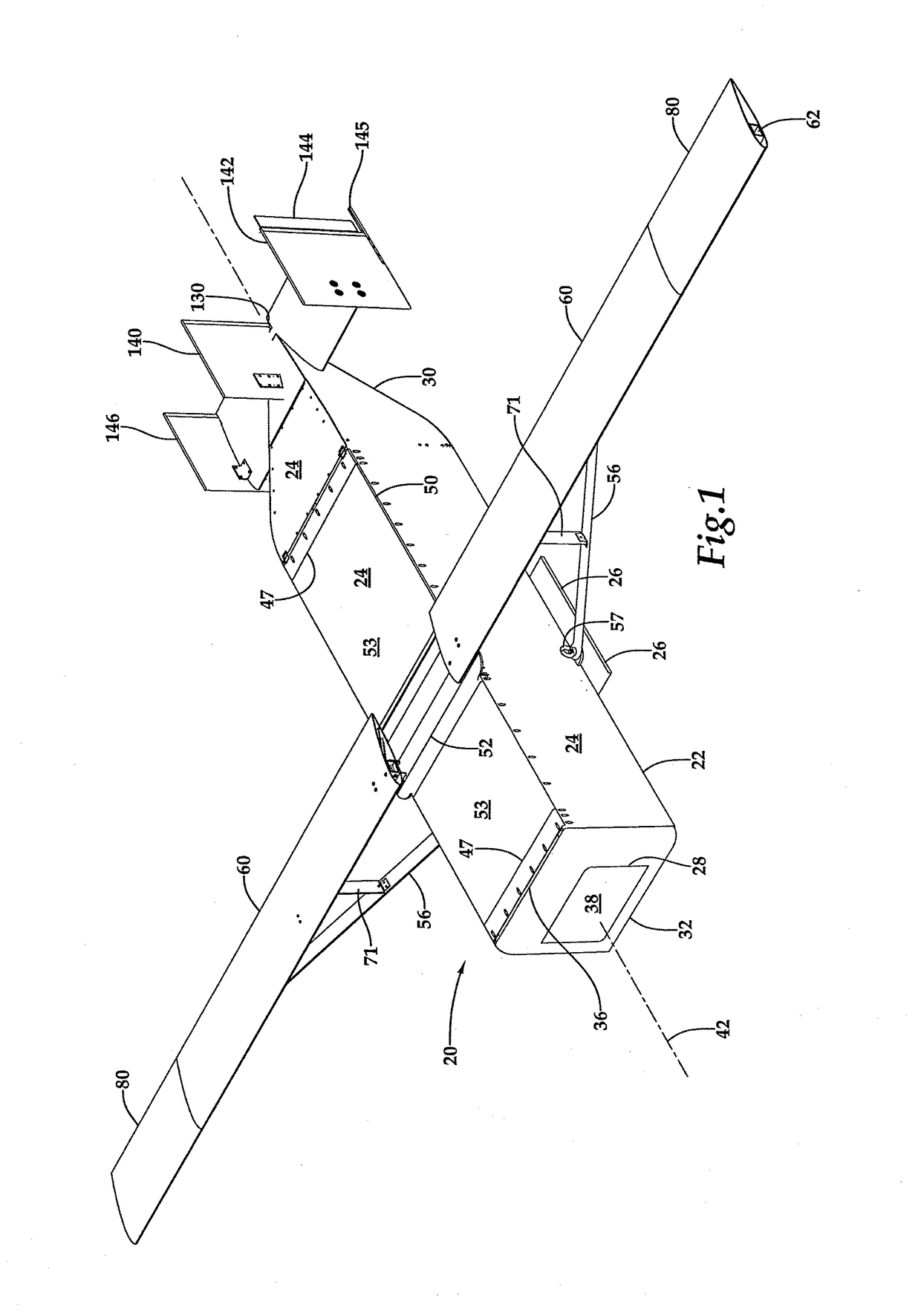

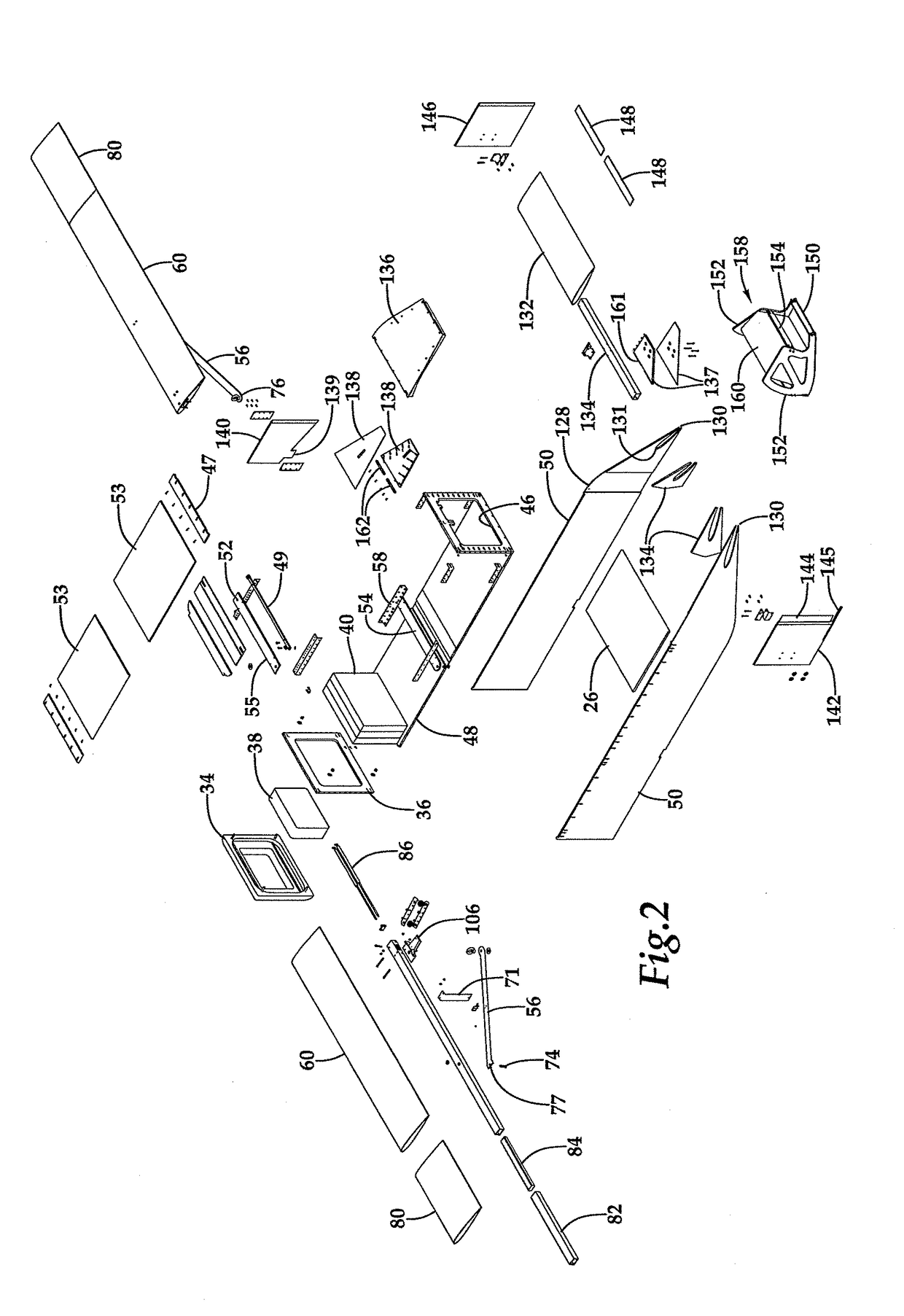

[0024]Referring more particularly to FIGS. 1-8, the logistic glider 20 is shown in FIG. 1. The glider 20 is constructed of low cost materials and for ease of assembly such that no part of the glider need be recovered for reuse. The fuselage 22 of the glider 20 is constructed as a rectangular box formed of medium or high density overlay plywood panels 24. This type of plywood is also known as signboard; it is impregnated with a resin which produces a smooth water resistant surface but has a cost not significantly greater than that of ordinary structural plywood. As shown in FIG. 2 the fuselage begins with a skid board 26 which forms the lowermost structure which is attached to the fuselage proper. The skid board 26 forms a launch skid which remains with the glider 20 after it is airdropped from a cargo aircraft used to deploy the glider. The skid board obviates the need for any component other than the logistic glider 20 from being dropped from the aircraft as part of the deployment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com