Oscillation dusting machine

A technology for dust collectors and racks, which is applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of offsetting time advantages, scattered cloth, and waste of labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

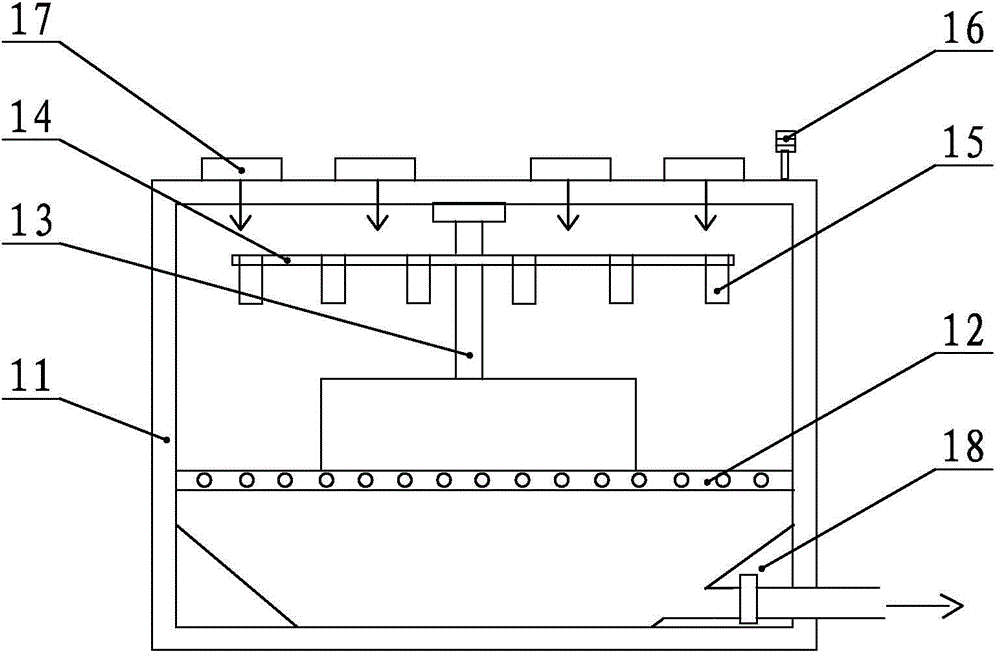

[0019] refer to figure 1 and 2 , the oscillating dust collector provided by the present invention includes a frame 11, and a dust falling plate 12 is horizontally arranged inside the frame 11 to divide the internal space into upper and lower parts. 14 is provided with a ring of vibrating devices 15 at equal intervals in the radial direction, and an indicator light 16 communicated with the vibrating device 15. The dust-falling plate 12 is provided with a through hole passing through the upper and lower side spaces; The air blower 17 is provided with an air suction blower 18 on the lower side of the dust falling board 12 .

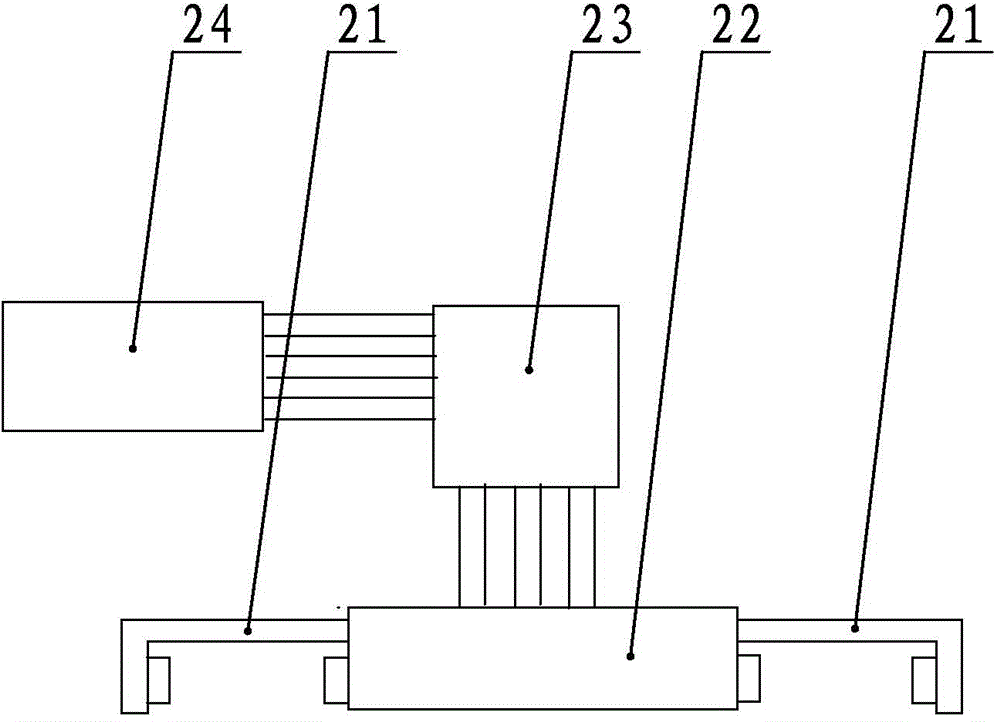

[0020] Wherein, the vibrating device 15 includes a transverse vibrating cylinder 24 and a longitudinal vibrating cylinder 23 which are connected to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com