Wood chipper

A chipper and machine body technology, applied in the field of chippers, can solve the problems of increasing work efficiency, poor chip removal, affecting work efficiency, etc., and achieve the effect of improving work efficiency and speeding up the efficiency of chip removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

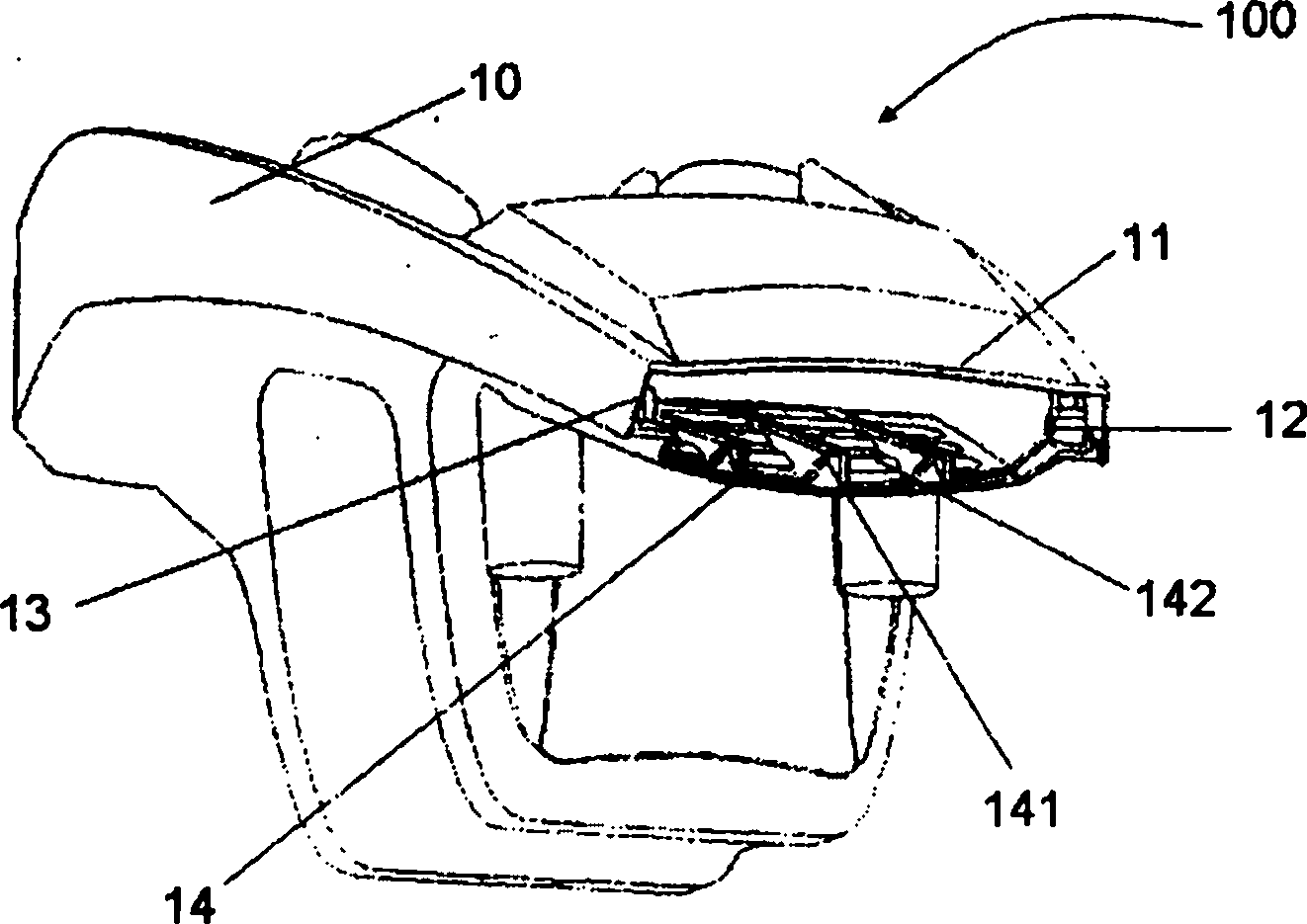

[0022] see figure 1 As shown, in an embodiment of a chipper 100 according to the present invention, it includes an organic body 10 and a chip outlet arranged at the lower end of the body.

[0023] Wherein the chip outlet is surrounded by the upper wall 11 , the two side walls 12 , 13 and the lower wall 14 . The surface of the lower wall 14 is set as a curved surface, and a plurality of tooth-shaped protrusions 141 are arranged on it, and a stepped shape 142 is formed between the two tooth-shaped protrusions 141 .

[0024] The distance from the highest point of the serrated protrusion 141 to the upper wall 11 is less than the maximum distance specified by the safety regulations. In this way, the safety inspection tool cannot enter the shredder through the chip outlet, so it meets the safety standards. Since the lower wall of the chip outlet is a curved surface with tooth-shaped high points and low points, and the distance from the low point to the upper wall is greater than th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com