Duplex head milling machine

A double-head milling machine and milling head technology, which is applied to milling machines, milling machine equipment, large fixed members, etc., can solve the problems of reduced working efficiency of milling machines and increased technical requirements of operators, and achieves improved use safety, reduced labor intensity and safety. high performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

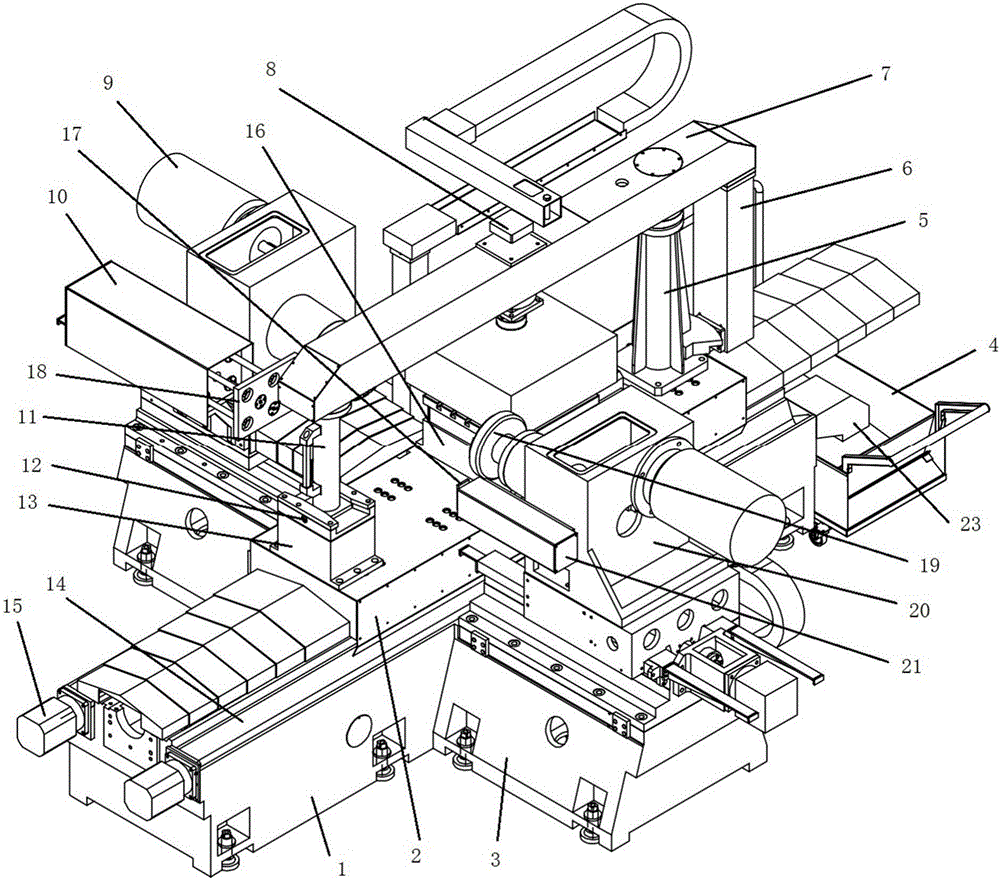

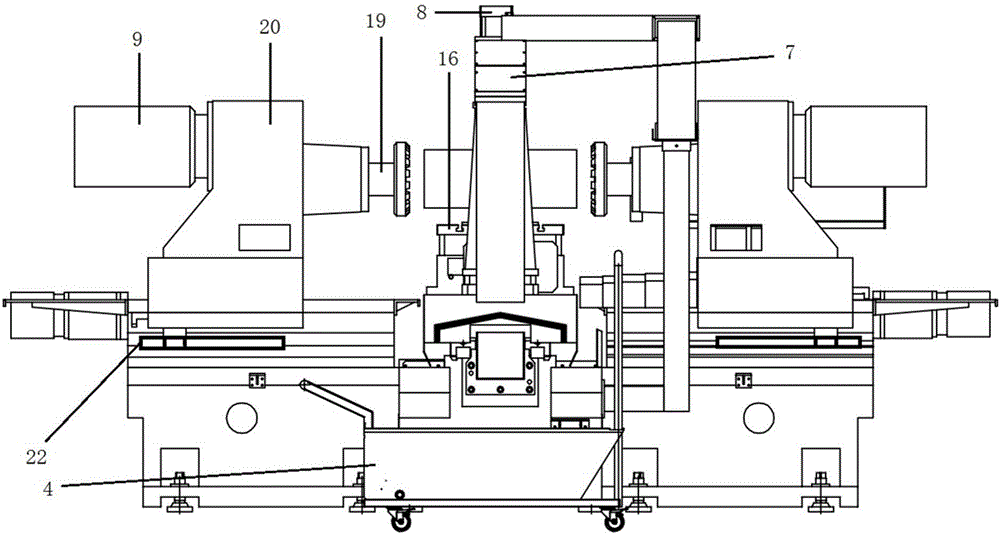

[0022] Such as figure 1 In the described embodiment, a double-head milling machine includes a base, a base 2, a rotary table 16, a beam 7, a column 5, two milling heads 19 and two transmission mechanisms, and the base 2 is placed in the center of the base and is slidingly connected with the base, the rotary table 16 is installed on the base 2, the beam 7 is placed above the base 2 and installed on the base 2 through the column 5, the transmission mechanism is placed on the base and slidably connected with the base, Wherein two transmission mechanisms are respectively placed on the left and right sides of the base 2 and symmetrically distributed, and the milling head 19 is installed on the transmission mechanisms. The base includes a main base 1 and two auxiliary bases 3. The cross-sectional shape of the base is cross-shaped, and the two auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com