Optical-mechanical structure for vertical machining center

A vertical, light-mechanical technology, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of affecting the service life of the light machine, the small internal space of the base, and affecting the processing accuracy, so as to achieve light weight and improve Efficiency and the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

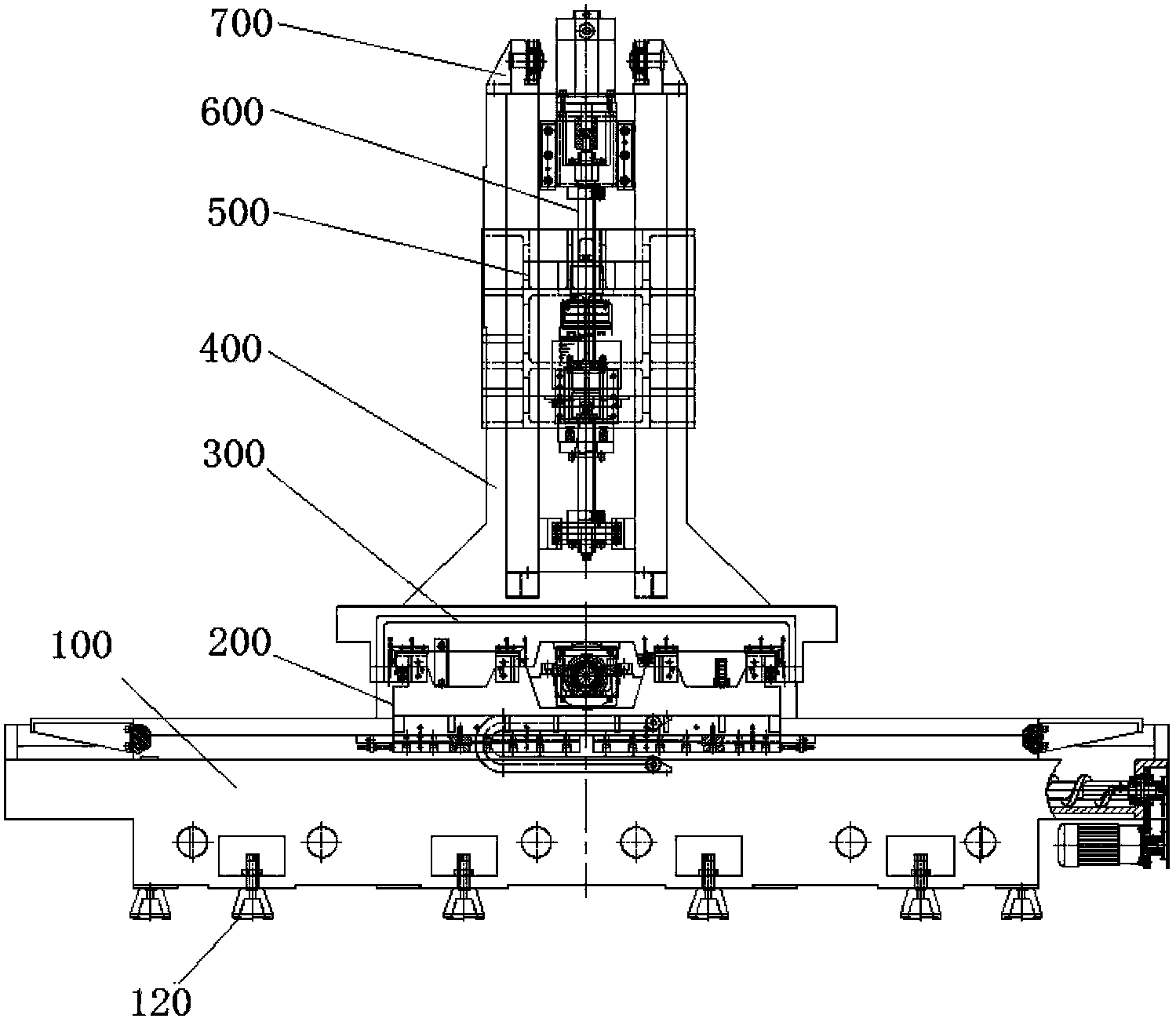

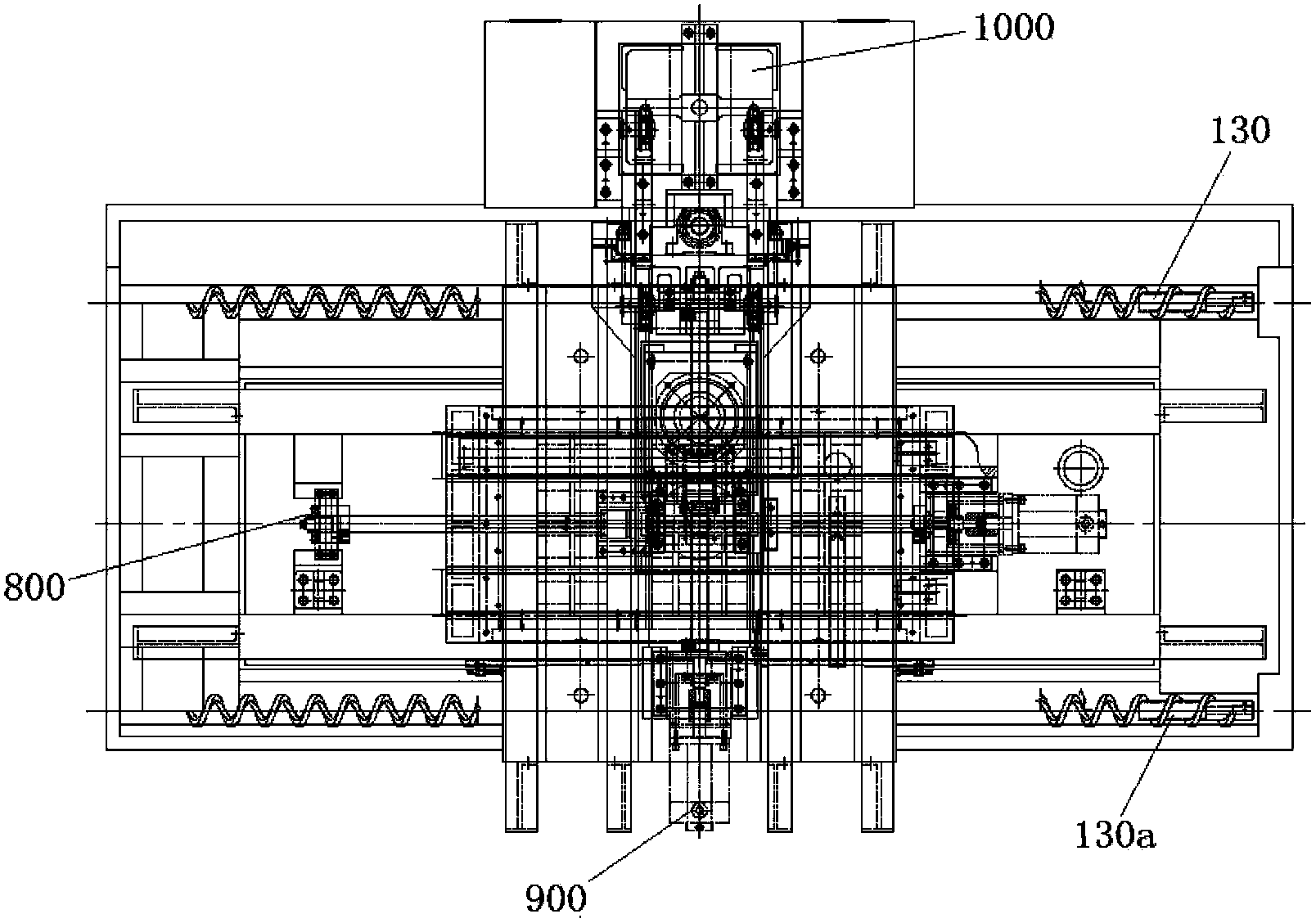

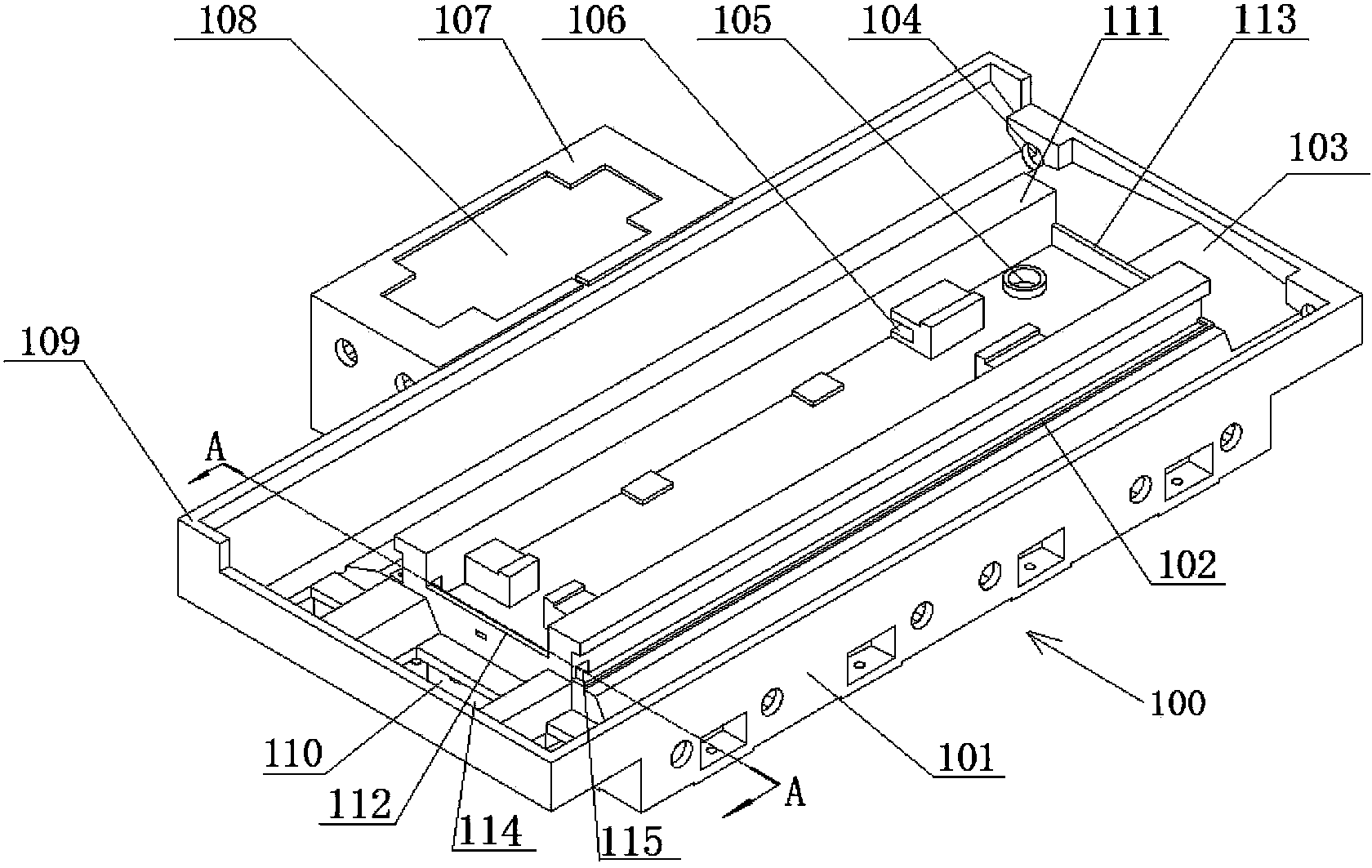

[0033] see figure 1 and figure 2 , the optical-mechanical structure of the vertical machining center shown in the figure includes a bed 100 and a column 400 fixed on the bed 100, a saddle 200, a worktable 300, a spindle box 500, a pulley 700, and an X-axis transmission mechanism 800 , Y-axis transmission mechanism 900, Z-axis transmission mechanism 600, weight balance device 1000, bed foot 120 is installed at the bottom of bed 100, is convenient to adjust the height position and level of bed 100.

[0034] The column 400 is set as the Z-axis, the Z-axis transmission mechanism 600 is installed on the column 400, the spindle box 500 is slidably arranged on the column 400 and connected with the Z-axis transmission mechanism 600, the pulley 700 is fixed on the top of the column 400, and the weight balance device 1000 is arranged on the column 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com