Chip blowing device for three-pin shaft fork

A technology of a three-pin shaft fork and an air supply device, which is applied to the cleaning method, cleaning method and utensils, and smoke and dust removal using gas flow, which can solve the problems of low chip removal efficiency and safety accidents, and achieve improved chip blowing efficiency, Optimize the use performance and improve the effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

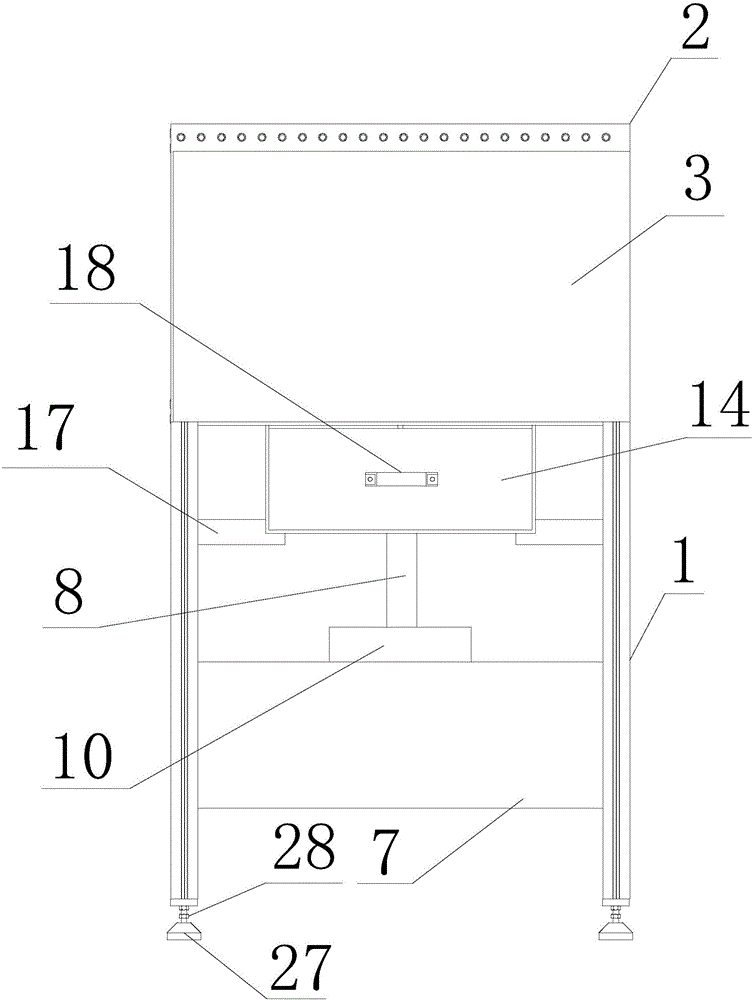

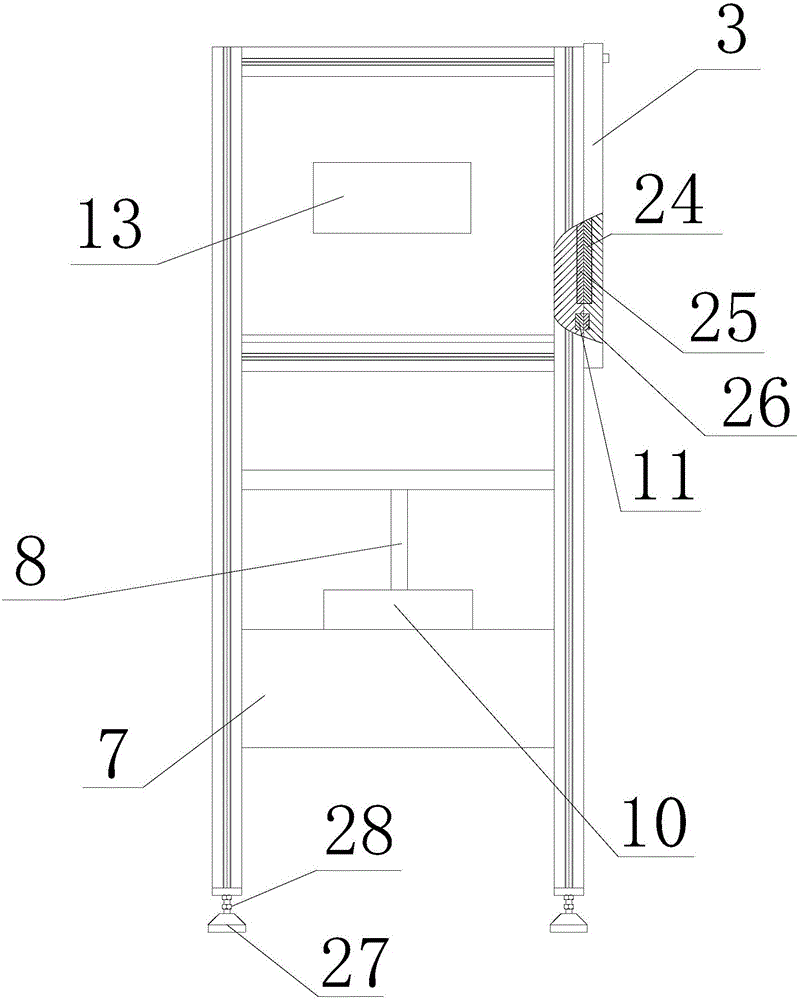

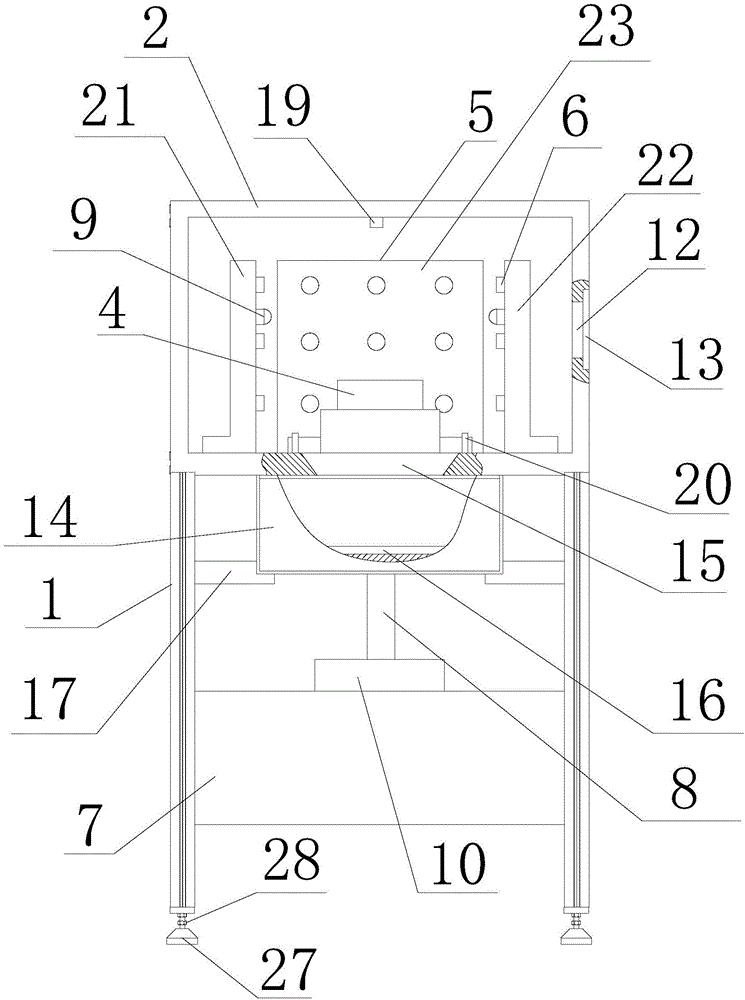

[0018] A chip blowing device for a three-pin shaft fork of the present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 , figure 2 , image 3 As shown, a chip blowing device for a three-pin shaft fork includes a frame 1, which is formed by welding angle steel or steel pipes, and a box body 2 is fixed on the frame 1, and the box body 2 is fixed on the On the frame 1, the box body 2 is provided with a workpiece placement opening, and the box body 2 is also provided with a closing plate 3 for closing the workpiece placement opening. The closing plate 3 is a leather curtain, and the upper end of the closing plate 3 is Fixed on the box body 2, the first positioning magnet 24 is bonded on the said closing plate 3, and the second positioning magnet 25 which is mutually adsorbed with the first positioning magnet 24 is bonded on the said box body 2; Flexible, technicians do not need to lift the entire leather curtain when pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com