Drill bit used for double-wall drill pipe reverse circulation drilling

A double-wall drill pipe and reverse circulation technology, which is applied to drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of incompatibility of manufacturing cost and structural strength, poor chip removal ability, etc., to ensure strength and reduce processing costs. , the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

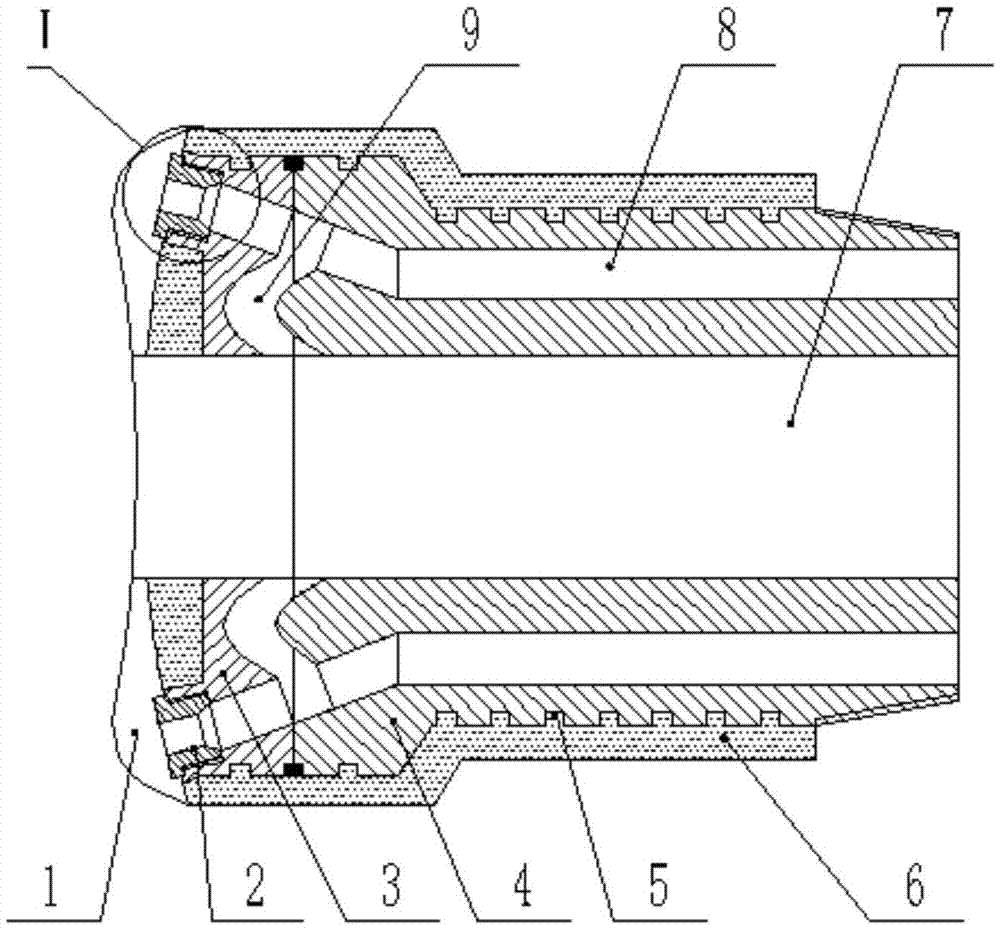

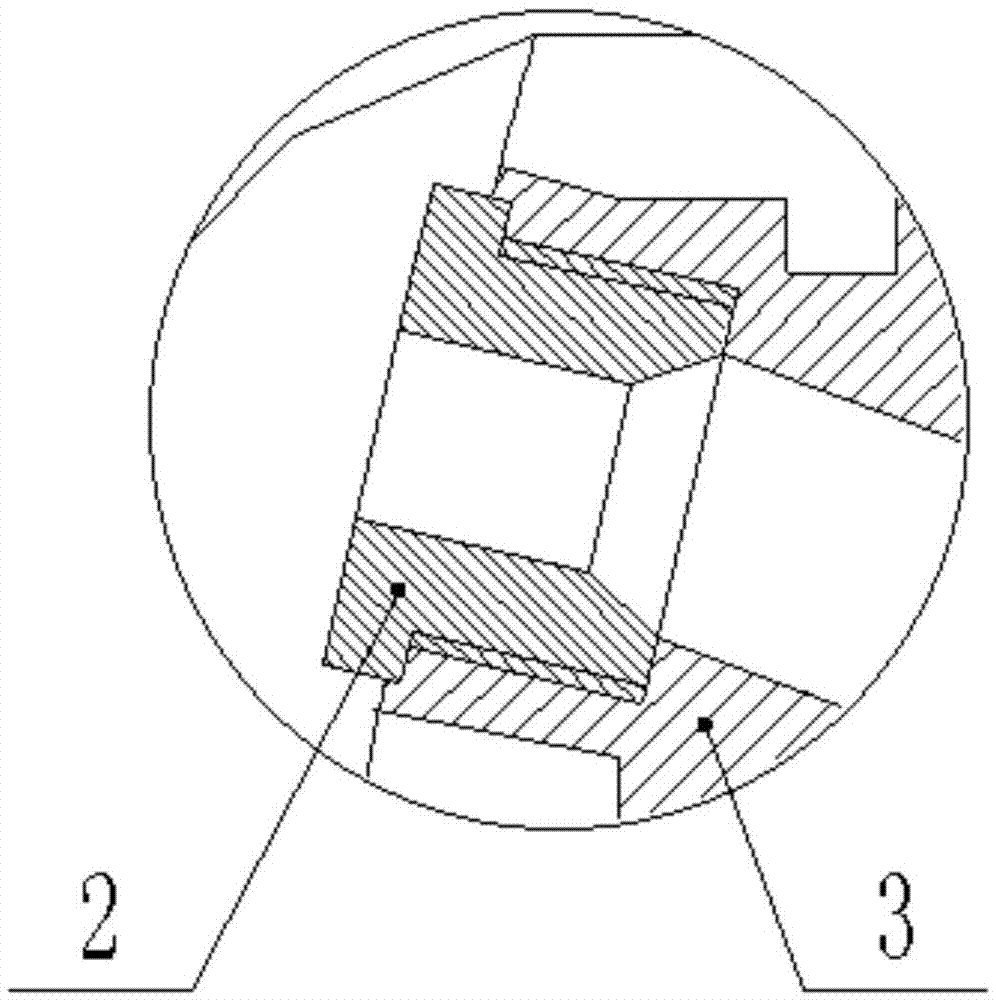

[0018] The present invention includes a drill bit body, the drill bit body includes a steel core and a tungsten carbide sintered layer 6, and an annular groove 5 is arranged on the outside of the steel core, and the tungsten carbide sintered layer 6 is sintered and filled around the steel core and on the drilling surface. In the annular groove 5 , the end of the tungsten carbide sintered layer 6 is provided with a blade 1 . The steel core is welded by the steel core main body 4 and the steel core end cover 3. The end of the steel core main body 4 away from the steel core end cover 3 is provided with threads for connecting double-walled drill pipes. The center of the steel core A chip removal flow channel 7 is provided, and a liquid injection flow channel 8 is arranged around the chip removal flow channel 7. One end of the liquid injection flow channel 8 located on the steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com