Band sawing machine with flying chip prevention function

A band sawing machine, functional technology, applied in the direction of sawing machine, sawing machine accessories, manufacturing tools, etc., can solve the problems of uncompact structure, scattered sawdust, damage to machine tool parts, etc., to improve the production environment, increase the service life, and guarantee The effect of production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

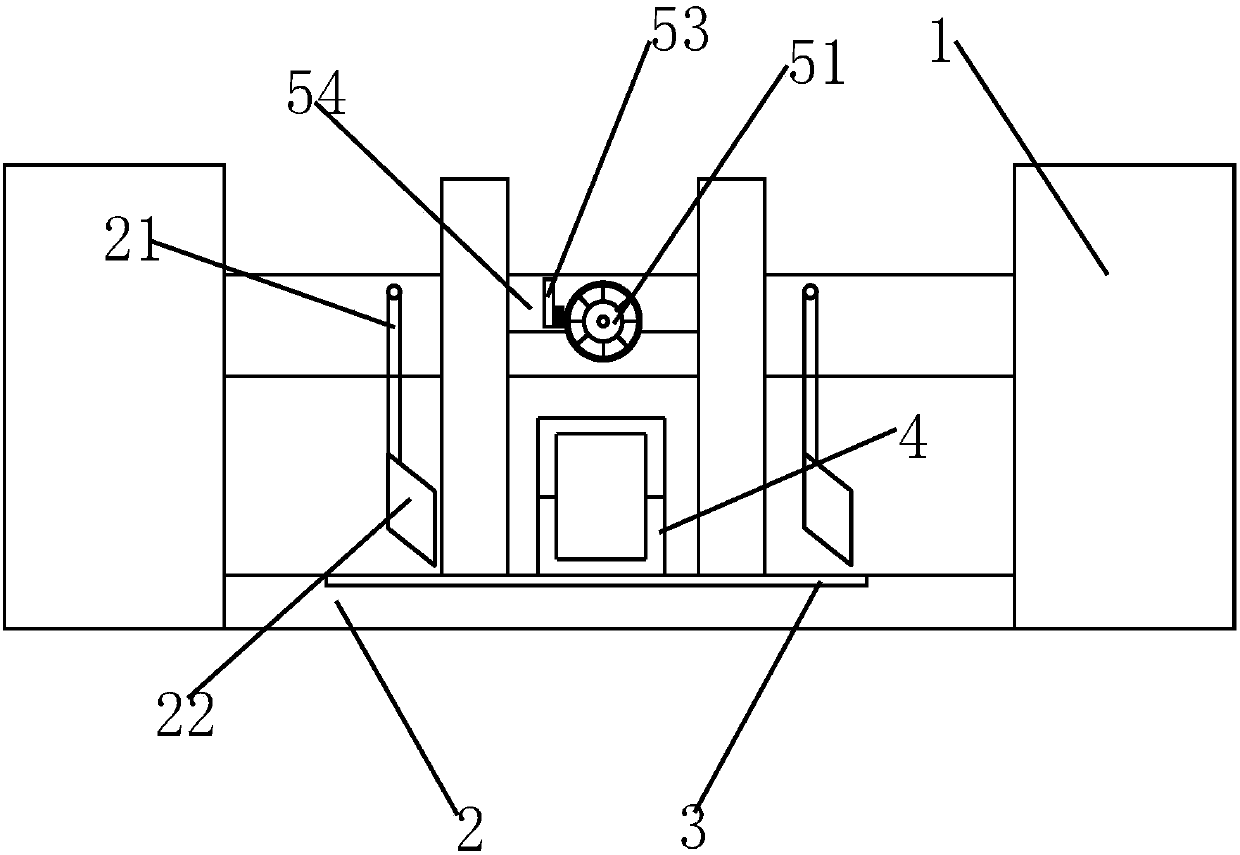

[0019] refer to figure 1 , the present invention provides a band sawing machine with the function of preventing flying chips, including a machine tool body 1, a sawing table 2 and a sawing beam are provided on the machine tool body 1, and a sawing table 2 located on the sawing beam is provided on the sawing beam. For the band saw above, the machine tool body 1 is also provided with a waste trough 3, and the saw table 2 is provided with a clamping device for clamping parts and two symmetrically arranged guide arms 21, the guide arms 21 is connected with a hydraulic cylinder, and the guide arms 21 are respectively provided with a chip-stopping main board 22, and the chip-stopping main board 22 is perpendicular to the longitudinal axis of the guide arm 21 and is located at the band saw guide where the guide arm 21 is located, so that The splashed debris ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com