Turnover tongue shearing device of plastic winding drum turnover tongue device

A shearing device and plastic technology, applied in metal processing and other directions, can solve the problems of lack of chip collecting function and affecting the stable operation of the tongue turning shearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

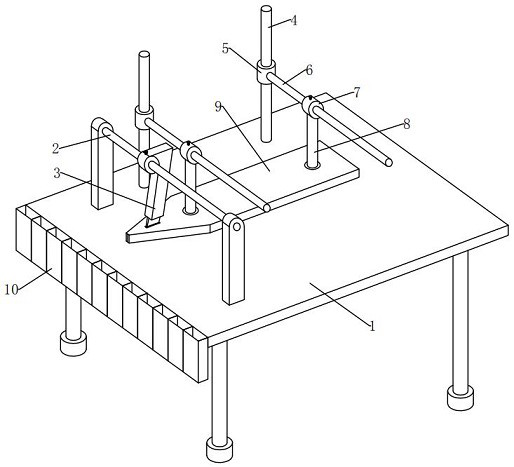

[0048] see Figure 1-2 , In the embodiment of the present invention, a tongue-turning shearing device of a plastic reel tongue-turning device includes:

[0049] Rack 1, the top plate of the rack 1 is in the shape of an inclined flat plate with an included angle of 20° to the horizontal plane, the top side of the rack 1 is fixedly installed with an adjusting rod 2 at the front of the outer front, and the top position of the adjusting rod 2 is movably installed with a cutting Knife 3, the front and rear parts of the left end of the top side outer surface of the frame 1 are located at the rear of the adjustment rod 2, respectively, and a fixed rod 4 is fixedly installed in the vertical direction. The middle end of the outer surface of the fixed rod 4 is installed with a first set Pipe 5, the right end position of the first sleeve 5 is fixedly installed with a cross bar 6 in a horizontal direction, the outer surface of the cross bar 6 is movably installed with a second sleeve 7, a...

Embodiment 2

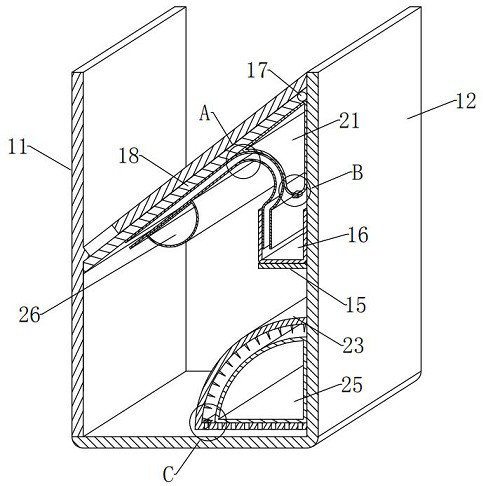

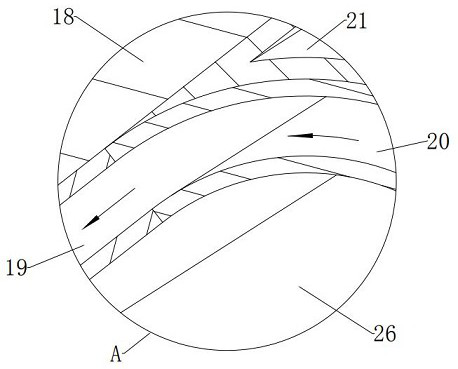

[0063] see Figure 2-4 and Figure 6-7 , the difference between the embodiment of the present invention and the embodiment 1 is that the preprocessing component 13 includes:

[0064]The fixing plate 15, the lower end of the right inner wall of the baffle 12 is fixedly installed with the fixing plate 15 in the horizontal direction, and the outer surfaces of the front and rear sides of the fixing plate 15 are fixedly installed at the lower part of the right end of the front and rear inner walls of the housing 11;

[0065] The material holding tank 16, the top side outer surface of the fixing plate 15 is fixedly installed with the material holding tank 16, and the appearance of the material holding tank 16 is in the shape of a letter "U" which is hollow inside on a longitudinal section, and the front and rear lengths of the material holding tank 16 are equal to The front and rear lengths of the fixed plate 15, the right outer surface of the material trough 16 is fixedly installe...

Embodiment 3

[0082] see figure 2 and Figure 5-7 , the difference between the embodiment of the present invention and the embodiment 1 is that the post-processing component 14 includes:

[0083] The bearing plate 23, the lower surface of the right inner wall of the baffle plate 12 is fixedly installed with the bearing plate 23, and the appearance of the bearing plate 23 in a longitudinal section is a 1 / 4 circle shape with an inner hollow, an open right end, a convex upper left, and a horizontal bottom end, The top of the right end of the carrier plate 23 is fixedly installed on the lower end surface of the right inner wall of the baffle plate 12, the bottom of the right end of the bearing plate 23 is fixedly installed on the bottom end surface of the right inner wall of the baffle plate 12, and the bottom end of the bearing plate 23 is equally adjacent to each other. Several through holes penetrating up and down;

[0084] The bearing plate 23 here has a 1 / 4 circle shape with an inner ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com