Automatic conveyer of work piece

A handling device and automatic technology, applied in the directions of transportation and packaging, manufacturing tools, conveyor objects, etc., can solve the problems of inapplicable grasping and handling, low work efficiency, complex structure, etc., to improve handling rigidity and load capacity, Reliable adsorption and the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

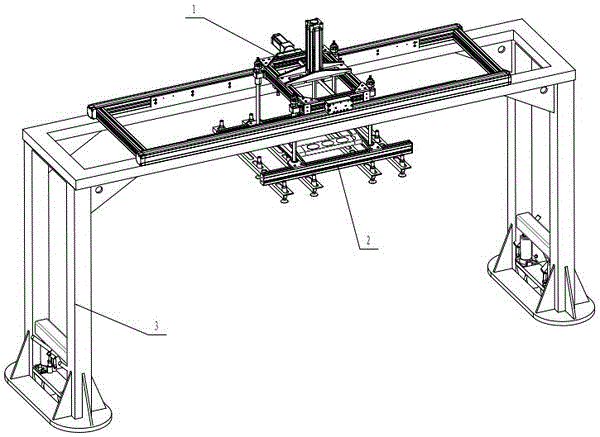

[0055] An automatic workpiece conveying device includes a conveying robot 1 , an adsorption system 2 , and a mobile support mechanism 3 . The handling robot 1 is a two-axis robot, and the two-axis robot includes a horizontal motion mechanism and a vertical motion mechanism, and the vertical motion mechanism is fixedly connected to the horizontal motion mechanism through screws.

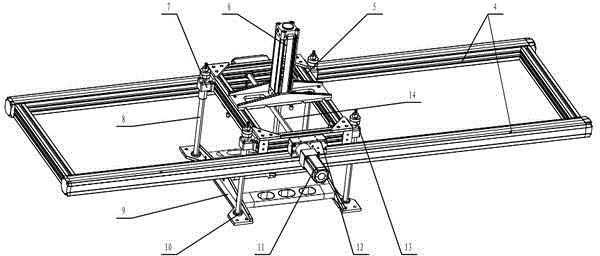

[0056] The invention adopts the double synchronous belt module 4 synchronous driving mode in the horizontal direction, and the horizontal conveying process has the characteristics of high speed, high rigidity, high load capacity and long conveying distance, which can adapt to the high-speed production frequency of existing punching machines and improve production efficiency.

Embodiment 2

[0058] An automatic workpiece conveying device includes a conveying robot 1 , an adsorption system 2 , and a mobile support mechanism 3 . The handling robot 1 is a two-axis robot, and the two-axis robot includes a horizontal motion mechanism and a vertical motion mechanism, and the vertical motion mechanism is fixedly connected to the horizontal motion mechanism through screws.

[0059] The invention adopts the double synchronous belt module 4 synchronous driving mode in the horizontal direction, and the horizontal conveying process has the characteristics of high speed, high rigidity, high load capacity and long conveying distance, which can adapt to the high-speed production frequency of existing punching machines and improve production efficiency.

[0060] The horizontal motion mechanism includes a synchronous belt module 4, a crossbeam 15, a support frame 5, a transmission shaft 14 and a servo drive system 11. Two synchronous belt modules 4 are installed in parallel on the ...

Embodiment 3

[0065] An automatic workpiece conveying device includes a conveying robot 1 , an adsorption system 2 , and a mobile support mechanism 3 . The handling robot 1 is a two-axis robot, and the two-axis robot includes a horizontal motion mechanism and a vertical motion mechanism, and the vertical motion mechanism is fixedly connected to the horizontal motion mechanism through screws.

[0066] The invention adopts the double synchronous belt module 4 synchronous driving mode in the horizontal direction, and the horizontal conveying process has the characteristics of high speed, high rigidity, high load capacity and long conveying distance, which can adapt to the high-speed production frequency of existing punching machines and improve production efficiency.

[0067] The horizontal motion mechanism includes a synchronous belt module 4, a crossbeam 15, a support frame 5, a transmission shaft 14 and a servo drive system 11. Two synchronous belt modules 4 are installed in parallel on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com