Automatic production line for punch

An automatic production line and punching technology, applied in the field of mechanical processing punching machines, can solve the problems of low continuous productivity and automation, high labor intensity, and increase production costs, so as to improve labor intensity and production environment, reduce operating labor, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments and drawings:

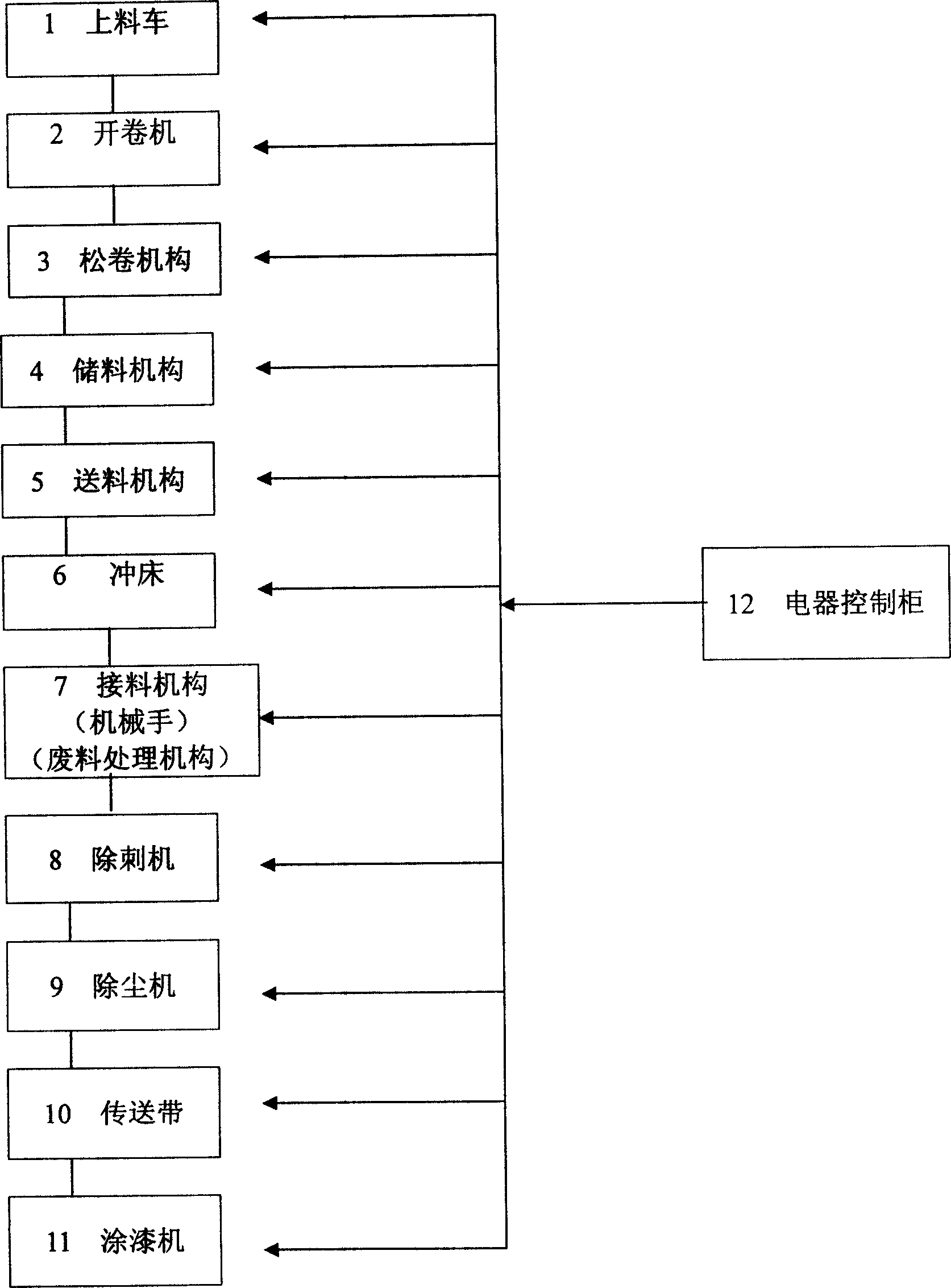

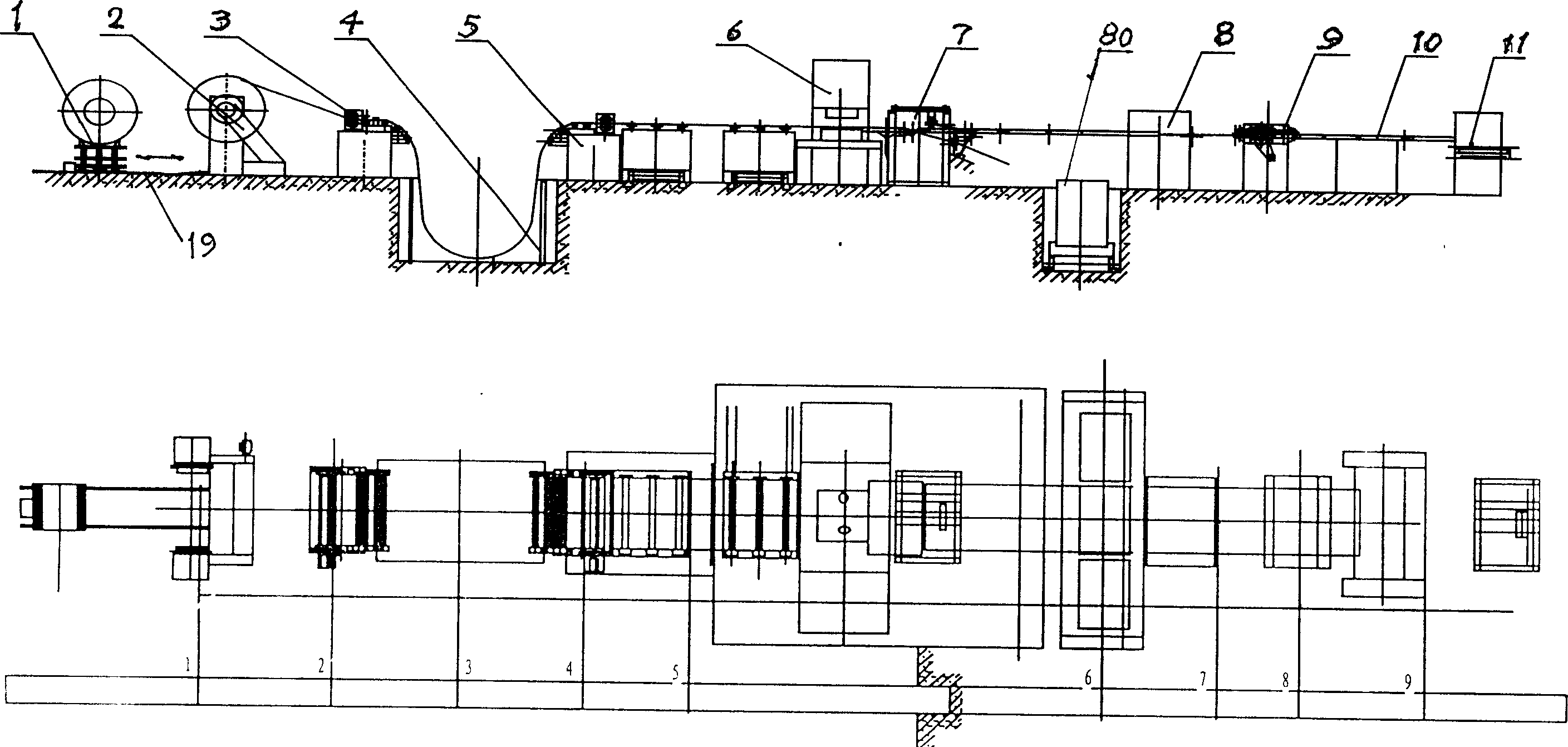

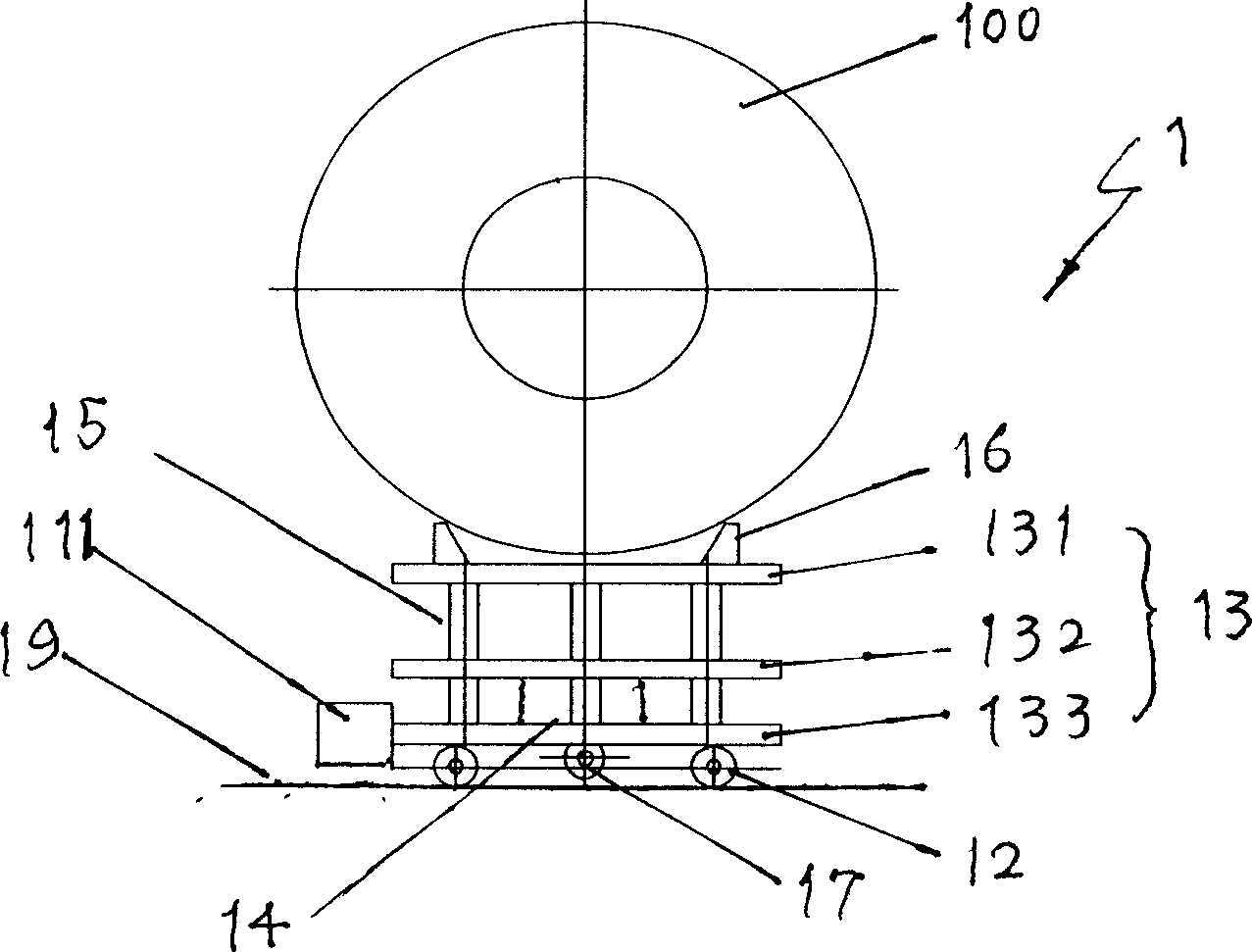

[0032] A punch automatic production line designed by the present invention (hereinafter referred to as the production line, see figure 1 , 2 ), including the deburring machine 8, the conveyor belt 10 and the painting machine 11 which are sequentially connected after the punch 6, characterized in that the uncoiler 2, the unwinding mechanism 3, the storage mechanism 4 and the feeding mechanism are sequentially connected before the punch 6 Mechanism 5; a material receiving mechanism 7 is also connected between the punch 6 and the puncture machine 8; a dust remover 9 is also connected between the puncture machine 8 and the conveyor belt 10; the connection mentioned here refers to the process Process connection, not mechanical connection. For example, between the uncoiler 2 and the unwinding mechanism 3, and between the unwinding mechanism 3 and the storage mechanism 4, onl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com