Device for positing bearing in twelve-point pressing bearing seat

A technology for positioning bearings and bearing seats, which is applied to metal processing equipment, forming tools, manufacturing tools, etc., to achieve the effects of increasing service life, reducing assembly difficulty, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

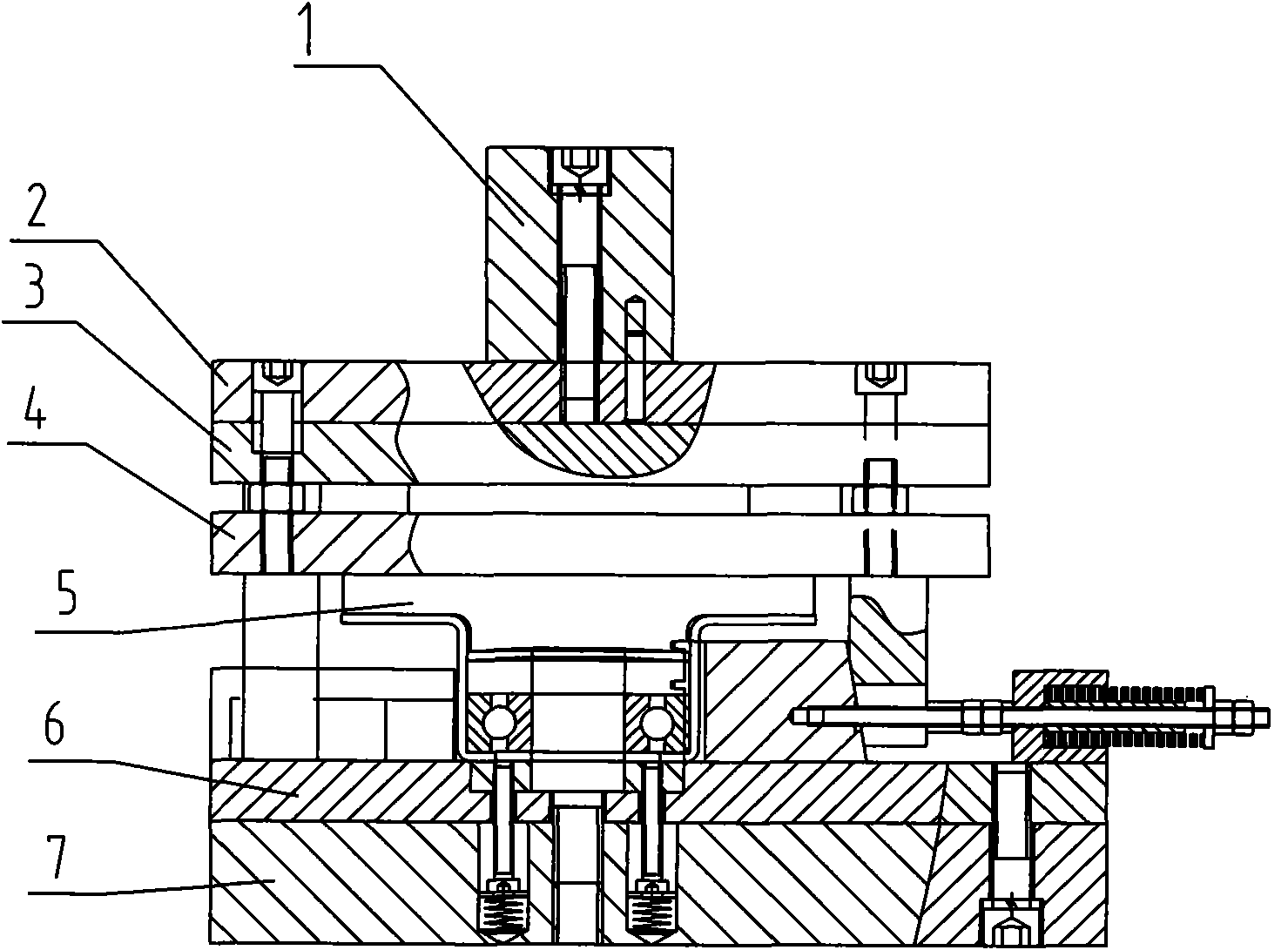

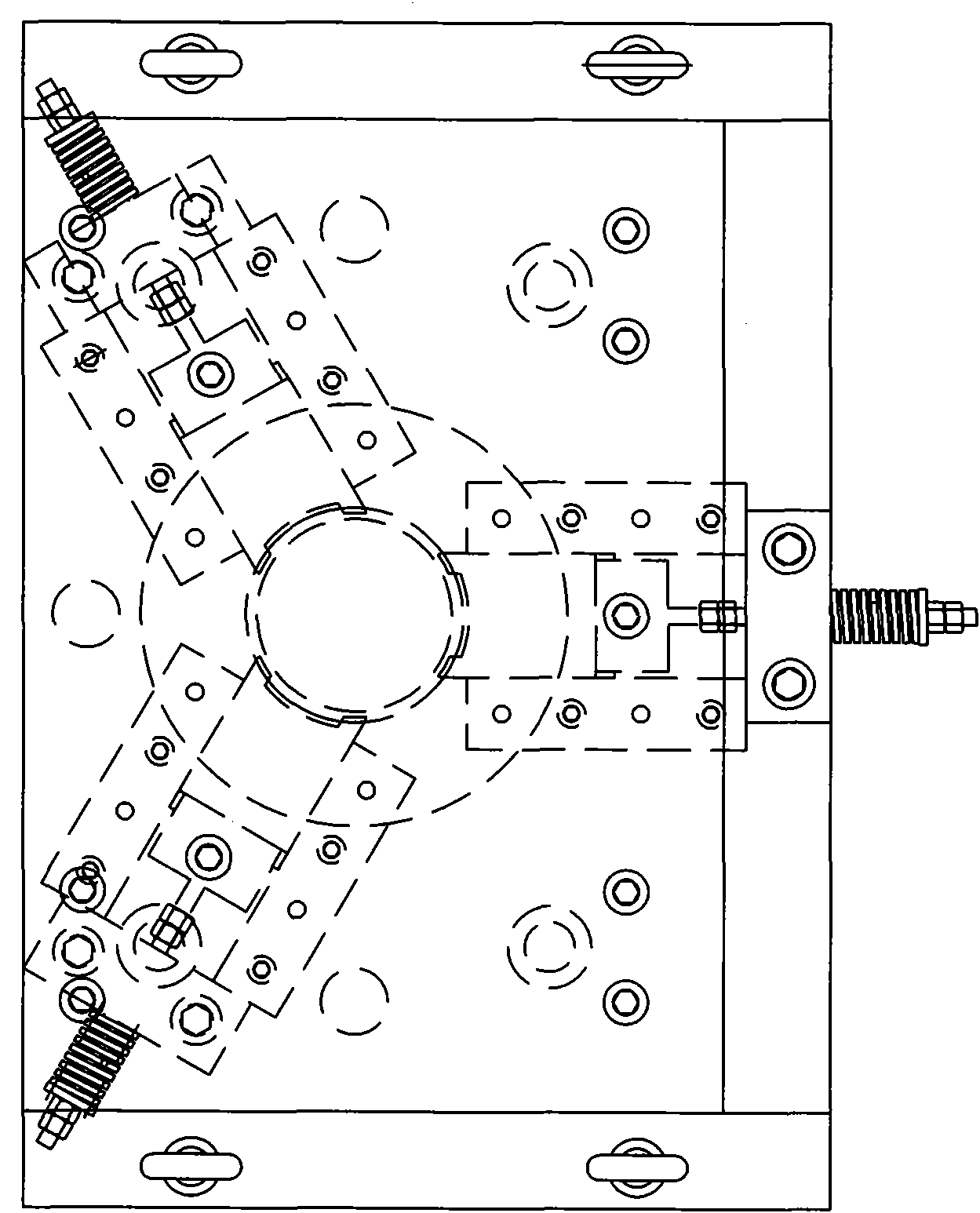

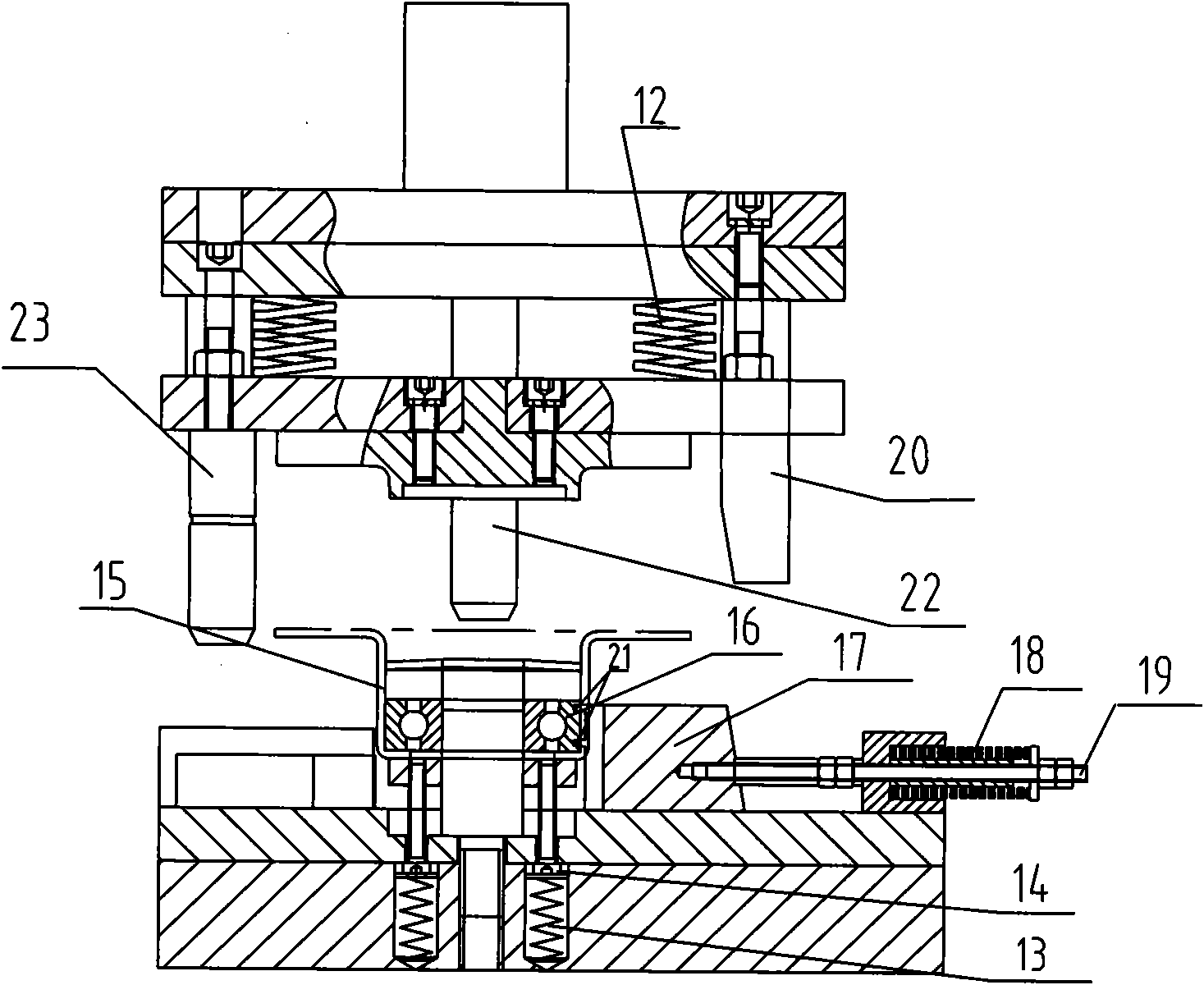

[0013] Such as figure 1 , figure 2 and Figure 4 As shown, the device for pressing the positioning bearing in the twelve-point bearing seat is composed of an upper die and a lower die matched with the upper die. The upper die includes connecting sleeve 1, top plate 2, upper plate 3, middle plate 4 and pressure block 5; the connecting sleeve 1 is connected and fixed on the top plate 2 through bolts and positioning pins, and the center line of the connecting sleeve 1 coincides with the center line of the punch press; the upper plate 3 and the lower surface of the top plate 2 are fixed together with bolts, and the middle plate 4 is connected with the upper plate 3 and the top plate 2 through bolts and can slide up and down through this connection mechanism; a group of large springs is symmetrically installed between the middle plate 4 and the top plate 2 12. One end of the large spring 12 is installed on the middle plate 4, and the other end passes through the upper plate 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com