Closed type rivet automatic producing device

An automatic production and closed technology, applied in mechanical equipment, metal processing equipment, nails, etc., can solve the problems of low cost, good safety, and high cost of fully automatic production equipment, and achieve the effect of low cost and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

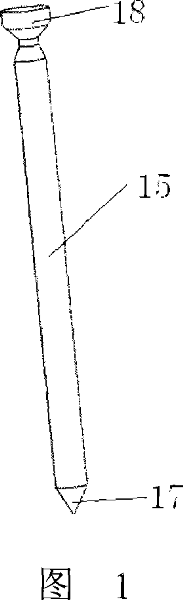

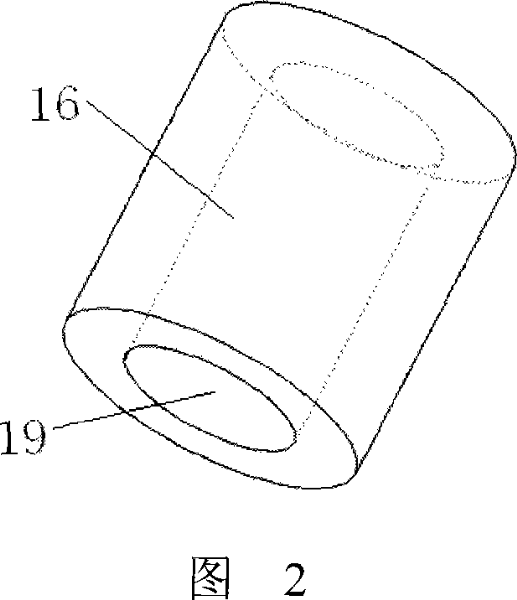

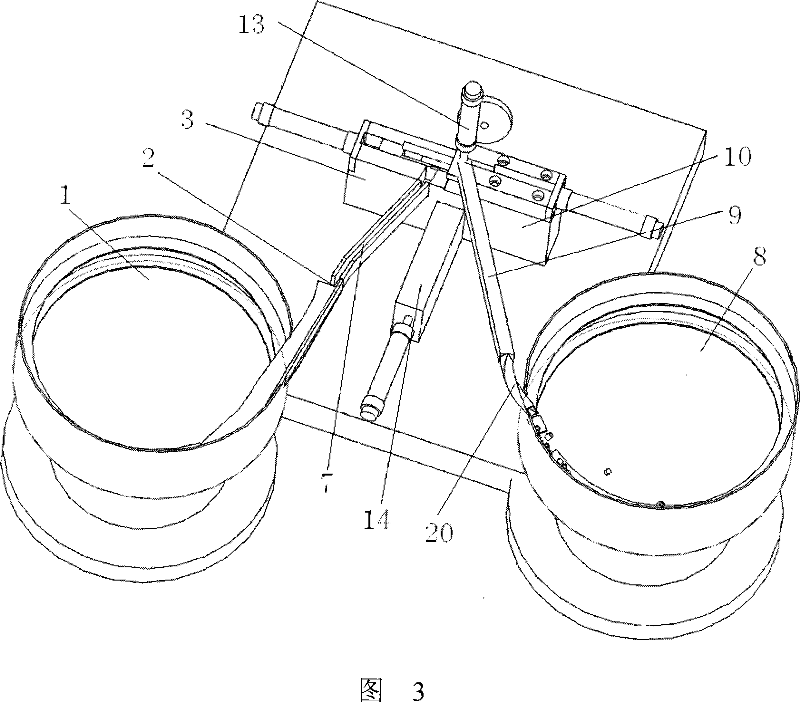

[0023] Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5, and Fig. 6, an automatic production equipment for closed rivets, including a punching machine, also includes a device for sorting scattered nails 15 into nail points 17 facing downwards and nail tails 18 The orderly nail queue facing upwards, and the nails 15 are sent to the nail feeding mechanism of the combined assembly station, used to organize the scattered caps 16 into an orderly cap queue with the cap opening 19 downward, and send the caps 16 The cap feeding mechanism that is sent to the combined assembly station, the assembly mechanism that is used to assemble the nails 15 and the pipe caps 16 in the combined assembly station into capped nails, and the punch hammer that is used to send the capped nails to the punch press The feeding mechanism below, the unloading mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com