Numerically-controlled sawing and punching integrated production line for aluminum frameworks

An aluminum template and production line technology, applied in other manufacturing equipment/tools, metal processing, manufacturing tools, etc., can solve problems such as slow production speed, low efficiency, and insufficient processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In order to clearly illustrate the technical characteristics of the present solution, the present invention will be further described below through specific implementation modes and in conjunction with the accompanying drawings.

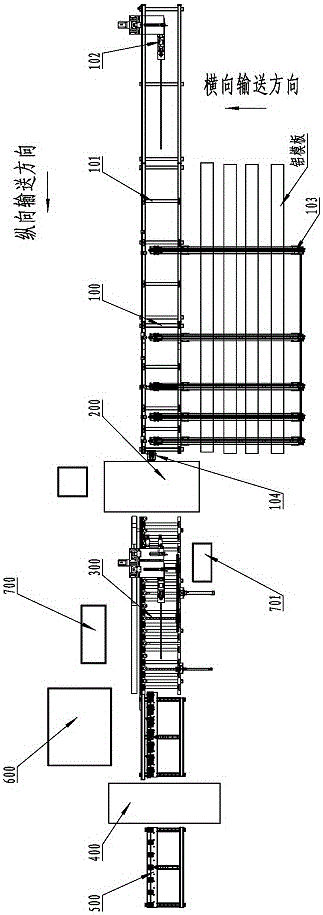

[0078] see figure 1 , a CNC sawing and punching integrated production line for aluminum templates, including a sawing machine feeder 100, a sawing machine 200, a sawing machine discharge and a punching machine feeder 300, a punching machine 400, a punching machine outlet 500, a hydraulic system 600 and an electrical control system 700.

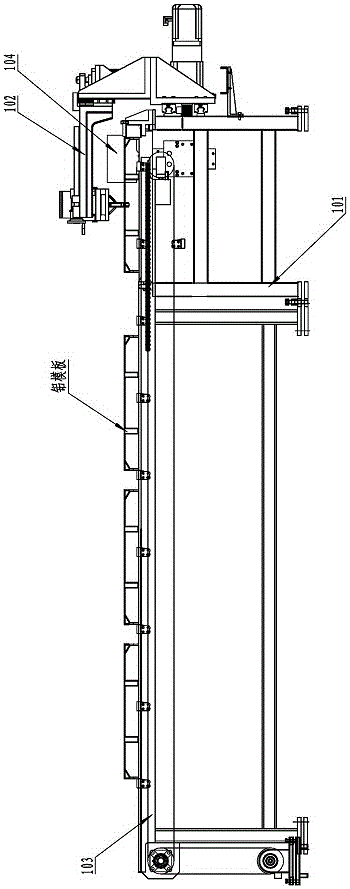

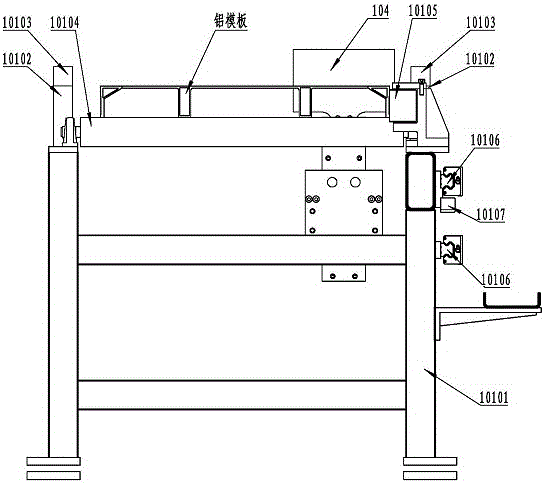

[0079] see Figure 1-Figure 4 , the sawing machine feeding device 100 includes a sawing machine feeding channel 101, and the sawing machine feeding channel 101 is provided with a roller shaft A10104, a side positioning roller A10105, and is driven by a servo motor A10202 and arranged on the sawing machine feeding frame 10101. The first guide rail 10106 of the sawing machine feeding trolley 102 is advanced, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com