Universal mold change trolley system

A mold trolley and general-purpose technology, applied in the field of general-purpose mold changing trolley systems, can solve the problems of different heights, low positioning accuracy, poor versatility, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

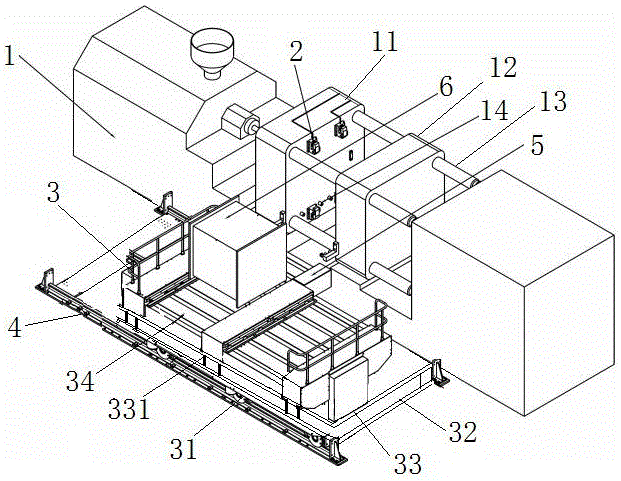

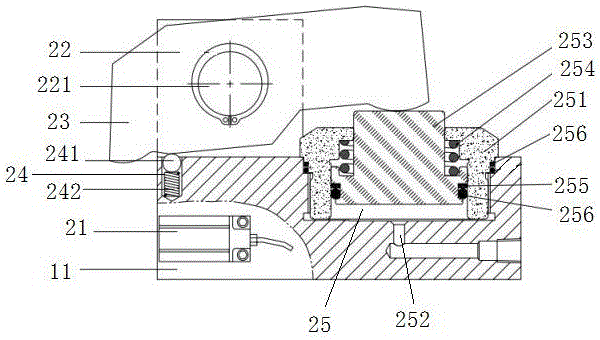

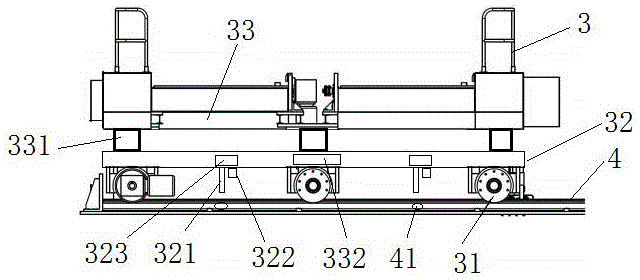

[0031] Such as Figure 1 to Figure 4 As shown, a general-purpose mold changing trolley includes an injection molding machine 1, a fixed template 11, a movable template 12, a horizontal guide column 13, a roller 14, a hydraulic locking fixture 2, a proximity switch 21, a support shaft 22, and a pin Shaft 221, pressing plate 23, groove one 24, steel ball 241, spring one 242, groove two 25, oil cylinder barrel 251, oil inlet and outlet 252, piston 253, spring two 254, back support ring 255, sealing ring 256, Die changing trolley 3, pulley 31, chassis 32, ground lock pin 321, proximity sensor 322, jacking base plate 33, lifting column 331, lifting column driving motor 332, lower blocking block 333, pressure sensor 334, mold changing platform 34, Main technical features such as transverse slide rail 4, ground lock hole 41, trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com