Integrated type full-automatic can making machine

A fully automatic, can-making machine technology, applied in the directions of forming tools, manufacturing tools, feeding devices, etc., can solve the problems of poor mold pulling performance, and achieve the effect of good equipment use, adjustable speed, and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

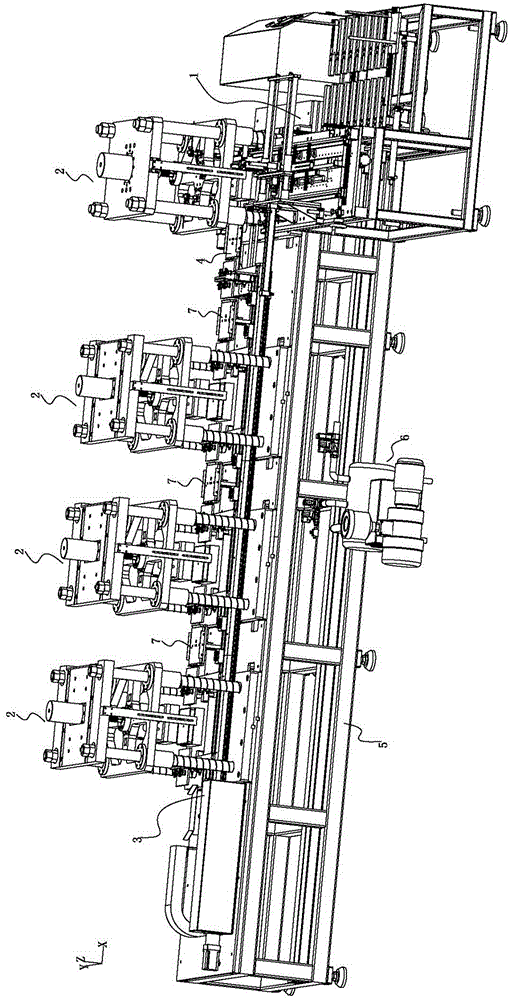

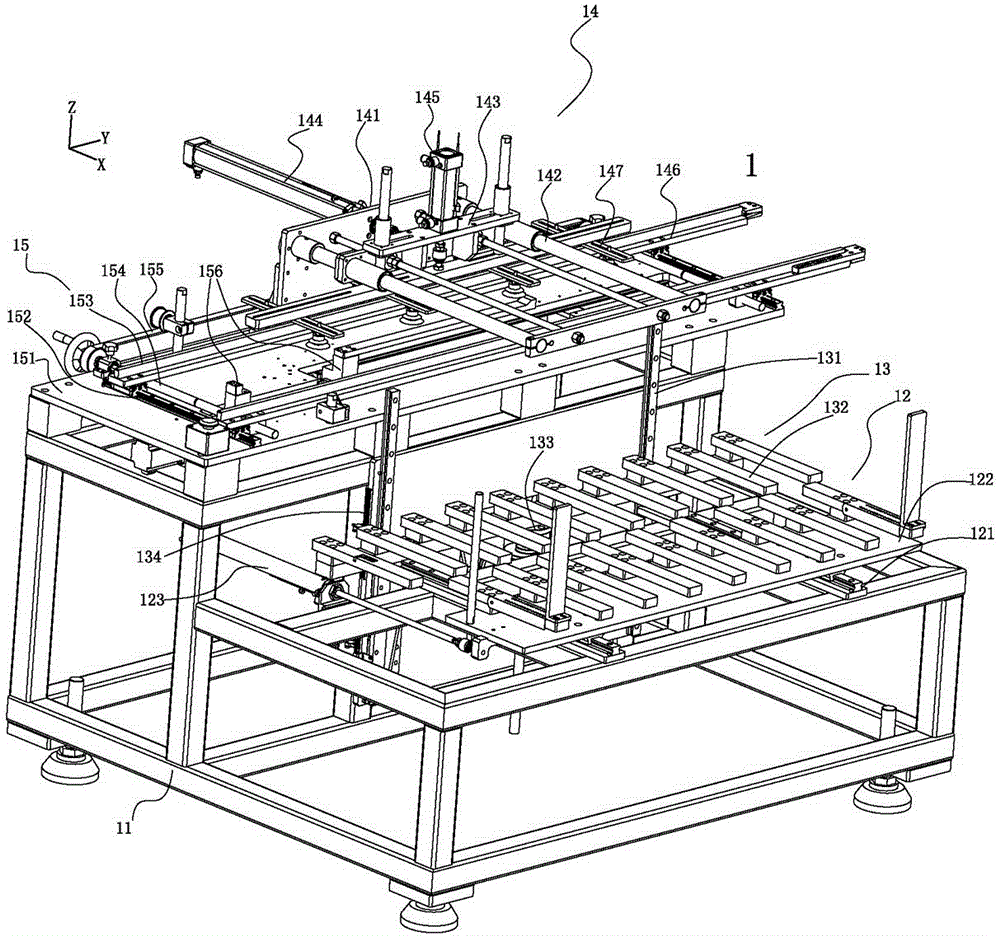

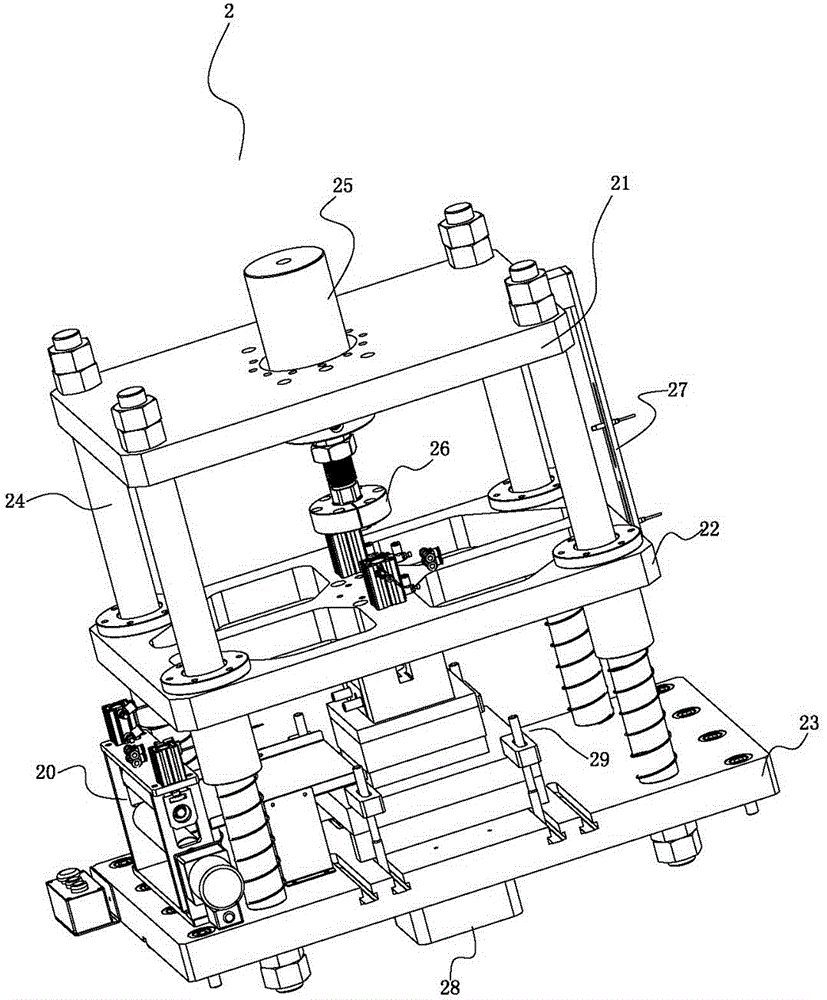

[0027] Attached below Figure 1-6 The present invention is described in further detail.

[0028] Reference attached Figure 1-6 , an integrated integrated automatic can making machine, used for special-shaped can making, including a control system, a frame 5, a number of mold frame mechanisms for stamping and forming of the tank body set on the frame 5, and setting the front end of the frame 5 The feeding mechanism 1 on the side and the hydraulic and pneumatic system 6 that provides driving power; the plurality of formwork mechanisms 2 include punching formwork mechanisms, trimming formwork mechanisms, flanging formwork mechanisms and shaping formwork mechanisms arranged at intervals in sequence ; The frame 5 is also provided with a material transfer mechanism 3 parallel to the plurality of formwork mechanisms 2, and the material transfer mechanism 3 includes a number of material transfer manipulators 32, and the plurality of material transfer manipulators 32 are arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com