Rapid mold changing structure of foaming molding apparatus

A foam molding and foaming mold technology, applied in the field of rapid mold change structure, can solve the problems affecting foam molding efficiency, large mold volume and weight, high labor intensity, etc., and achieve rapid replacement, shortening of replacement time and saving The effect of changing the mold time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

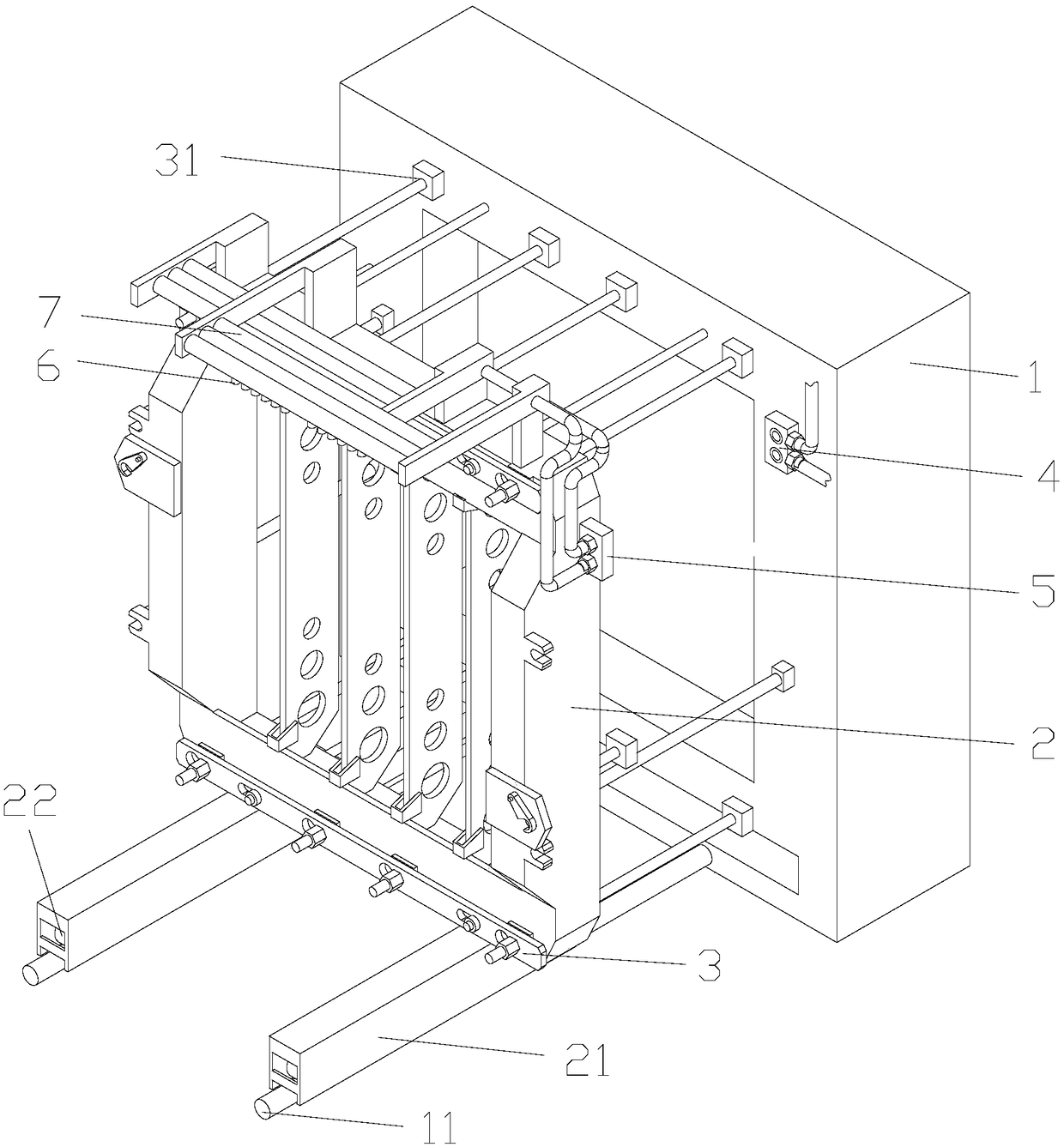

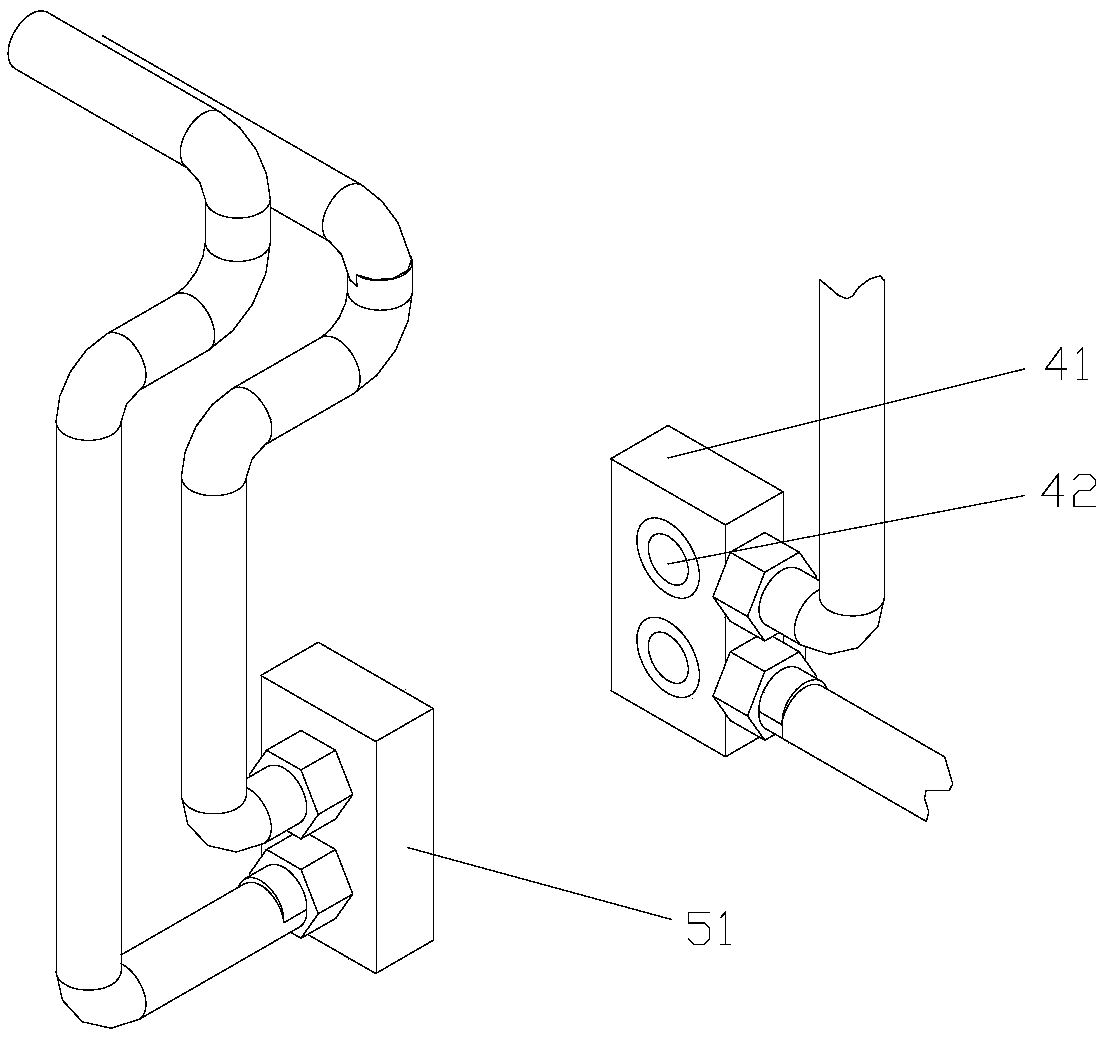

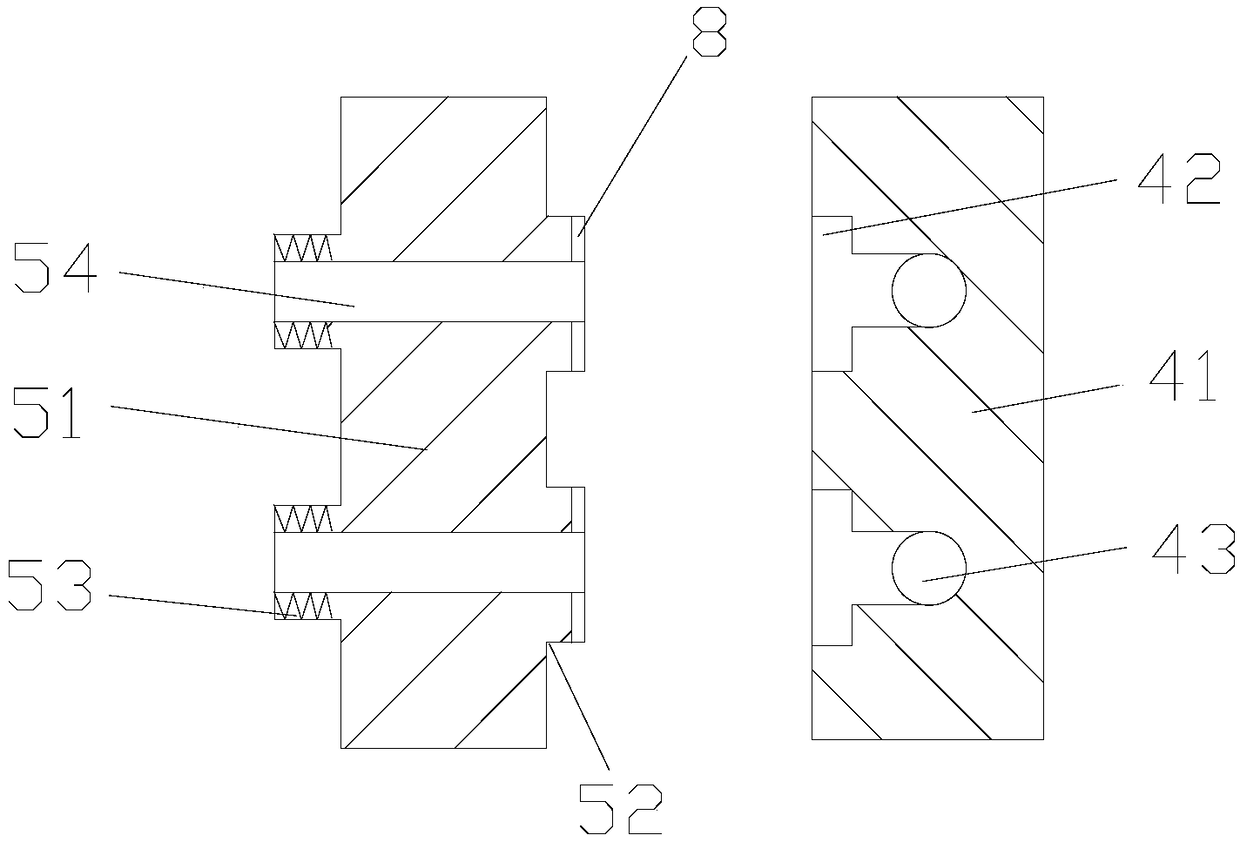

[0023] Specific examples: such as Figure 1-4 As shown, this embodiment provides a quick mold change structure of a foam molding device, including a foam molding device 1, a mold base 2 for installing a foam mold, and a mold base 2 for installing the foam molding The locking mechanism 3 on the device 1, the foam molding device 1 is provided with a guide rail 11, the mold base 2 is slidably installed on the guide rail 11, and the foam molding device 1 is provided with a first fast valve for outputting gas. Interface 4, the mold base 2 is provided with a second quick interface 5 for fast docking with the first quick interface 4, and the mold base 2 is also provided with several ports for feeding gas into the foaming mold Output ports 6, several output ports 6 are connected to the second quick interface 5 through connecting pipes 7.

[0024] In this embodiment, in order to slide the mold base 2 on the foam molding device 1 to reduce the installation difficulty of the mold base 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com