Alloy powder block used for built-up welding

A technology of alloy powder and surfacing metal, which is applied in the field of alloy powder block for surfacing welding and its preparation, which can solve the problems of difficult melting, difficult melting of base material and powder block, complicated manufacturing process, etc., to overcome the need for manual operation, high efficiency The effect of improving welding materials and process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

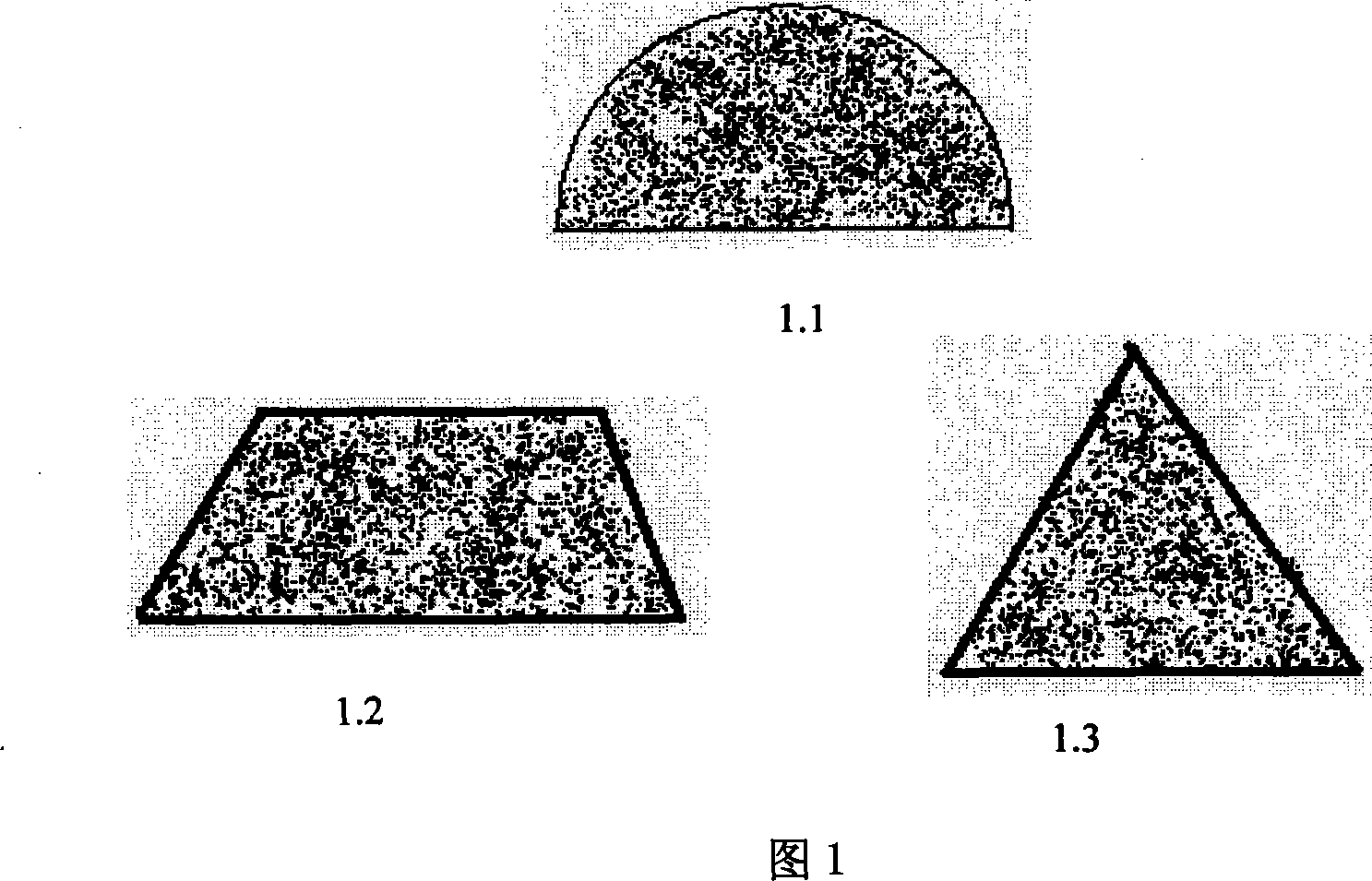

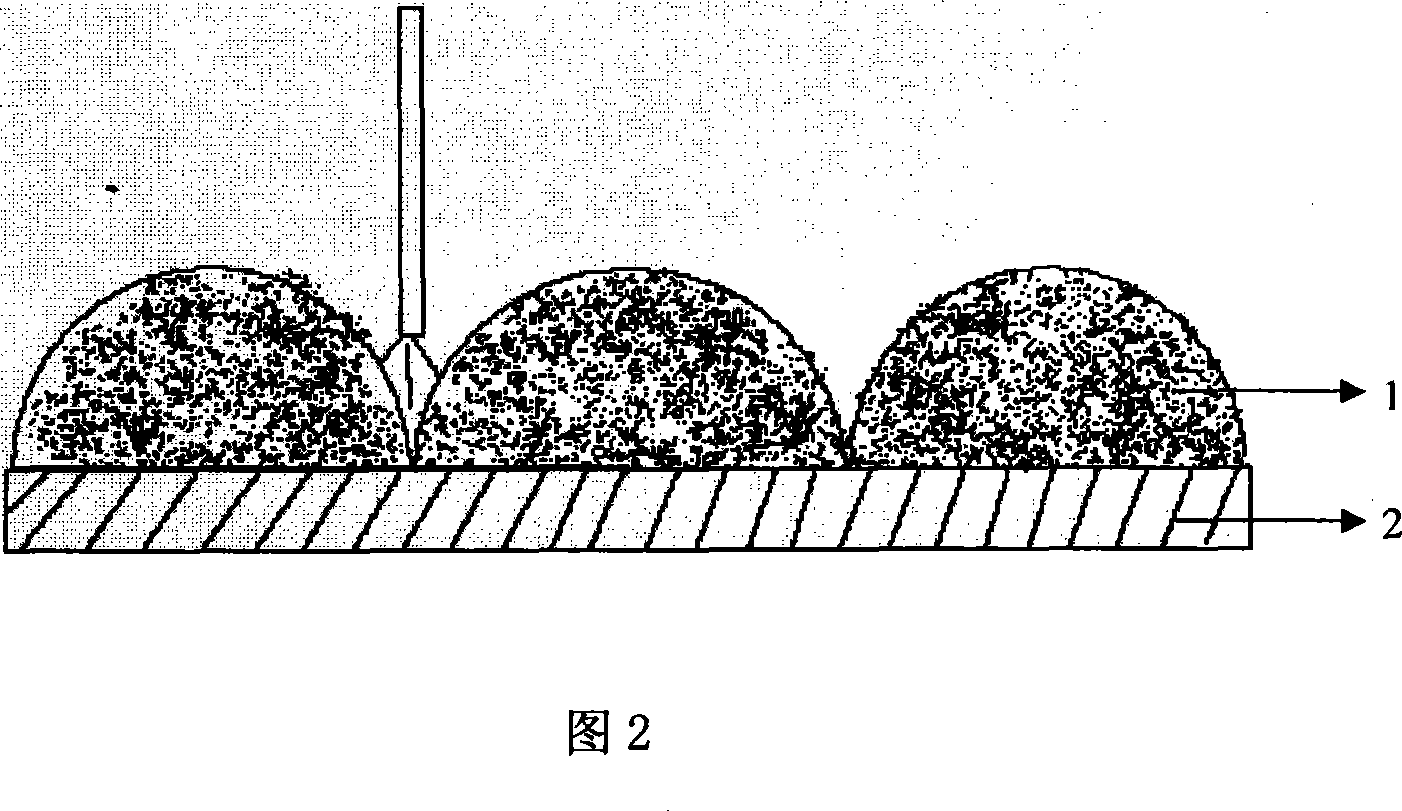

[0058] Example 1: Martensitic steel surfacing welding metal alloy powder block, the alloy system is C-Si-Mn-Cr-Mo.

[0059] The mass percent of the metal and alloy powder formula is 3.5% high-carbon ferrochrome (containing 65% Cr, 7% C, 3% Si), 3.5% medium-carbon ferromanganese (containing 79% Mn, 1.2% C), 1.9% ferrosilicon (containing 45% Si, 3% Mn), 1.8% ferromolybdenum (containing 57% Mo, 0.5% Si, 0.2% C), 0.14% graphite, and the rest is iron powder. The particle size of the powder is 50-300 mesh. Prepare the alloy powder according to the above ratio, and mix evenly, add 10% of the powder mass of sodium silicate binder and 4% of titanium dioxide, the modulus of the above-mentioned sodium silicate is 3.0, and the Baume degree is 50. Choose an equilateral triangle sizing die with a side length of 10mm, press the alloy powder block according to the production regulations of the welding rod, and do not feed the welding wire during the pressing coating process. Cut the pressed...

Embodiment 2

[0061] Embodiment 2: Austenitic high manganese steel surfacing welding metal alloy powder, the alloy system is C-Mn-Si-W.

[0062] The mass percent of metal and alloy powder formula is, 25.2% medium carbon ferromanganese (containing 79% Mn, 1.2% C), 3.5% ferrosilicon (containing 45% Si, 3% Mn), 1.1% graphite, 3.8% % of tungsten iron (containing 70% W, 0.4% C, 1.0% Si), and the rest is iron powder. The particle size of the powder is 50-300 mesh. Prepare the alloy powder according to the above ratio, and mix evenly, add 10% sodium silicate binder and 4% white mud accounting for the mass of the powder. The above-mentioned water glass has a modulus of 3.0 and a Baume degree of 50. A semicircular sizing die with a diameter of 10mm is selected, and the alloy powder block is pressed according to the production regulations of the welding rod, and the length of the alloy powder block is 200mm. The pressed alloy powder block is dried at a low temperature of 20°C for 24 hours at room ...

Embodiment 3

[0064] Embodiment 3: Austenitic chromium-manganese steel surfacing welding metal alloy powder block, the alloy system is C-Mn-Cr.

[0065] The mass percent of metal and alloy powder formula is, 25.6% medium carbon ferromanganese (containing 79% Mn, 1.2% C), 2.0% ferrosilicon (containing 45% Si, 3% Mn), 0.6% graphite, 21.0% % of metal chromium, the rest is iron powder. The particle size of the powder is 50-300 mesh. Prepare the alloy powder according to the above ratio, and mix evenly, add 10% sodium silicate binder and 4% titanium dioxide accounting for the mass of the powder. The above-mentioned water glass has a modulus of 3.0 and a Baume degree of 50. Select an isosceles trapezoidal sizing die with upper and lower bases of 8mm and 16mm respectively, and a height of 8mm, press the alloy powder block according to the production regulations of the welding rod, and the length of the alloy powder block is 100mm. The pressed core alloy powder is dried at a low temperature of 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com