High-uniformity steel plate with super-thick structure and manufacturing method thereof

A technology for uniformity and structure, applied in the field of high-uniformity and ultra-thick structural steel plates and their manufacturing, can solve the problems of low yield, high cost and unfavorable mass production, and achieve high yield, ensure uniformity of temperature structure, The effect of refining the grains of the internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

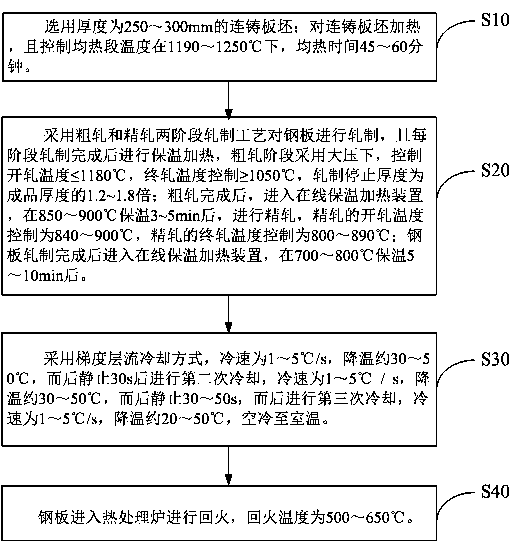

Method used

Image

Examples

Embodiment 1

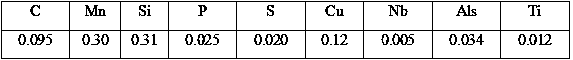

[0059] Table 1 The composition of steel billets used in Example 1, wt%

[0060]

[0061] The thickness of the billet is 250mm, the heating temperature is 1193°C, and the soaking time is 45min; the starting rolling temperature in the rough rolling stage is 1176°C, the rolling passes are 6, the final rolling temperature is 1148°C, the waiting temperature is 140mm, and after cooling to 870°C, enter The heat preservation device is kept warm for 5 minutes; the starting temperature of the finishing rolling stage is 865°C, the finish rolling temperature is 857°C, and the thickness of the finished product is 80mm; air cooling to 780°C enters the online heat preservation and heating device, and after holding for 5 minutes, the gradient laminar flow cooling method is adopted. 5°C / s, cooling to 750°C, then cooling for the second time after standing still for 30s, the cooling rate is 5°C / s, cooling to 720°C, then standing still for 40s, and then cooling for the third time, the cooling r...

Embodiment 2

[0063] Table 2 The composition of steel billets used in Example 2, wt%

[0064]

[0065]The thickness of the steel billet is 250mm, the heating temperature is 1211°C, and the soaking time is 55min; the starting rolling temperature in the rough rolling stage is 1147°C, 5 rolling passes, the final rolling temperature is 1126°C, the waiting temperature is 130mm, and after cooling to 852°C, enter The heat preservation device is kept warm for 4 minutes; the starting temperature of the finish rolling stage is 847°C, the finish rolling temperature is 839°C, and the thickness of the finished product is 90mm; it is air-cooled to 750°C and enters the online heat preservation and heating device. After 6 minutes of heat preservation, the gradient laminar flow cooling method is adopted. 4°C / s, cooled to 715°C, and then cooled for the second time after standing still for 30s. / s, cooled to 620°C, steel plate, and then air cooled to room temperature. Then enter the heat treatment furnace...

Embodiment 3

[0067] Table 3 The composition of steel billets used in Example 3, wt%

[0068]

[0069] The thickness of the steel billet is 300mm, the heating temperature is 1245°C, and the soaking time is 48min; the starting rolling temperature in the rough rolling stage is 1156°C, the rolling passes are 6, the final rolling temperature is 1135°C, the waiting temperature is 125mm, and after cooling to 895°C, enter The heat preservation device keeps heat for 3 minutes; the start rolling temperature in the finishing rolling stage is 879°C, the finish rolling temperature is 860°C, and the thickness of the finished product is 110mm; air cooling to 720°C enters the online heat preservation and heating device, and after 10 minutes of heat preservation, the gradient laminar flow cooling method is adopted. It is 3°C / s, cooled to 673°C, and then cooled for the second time after standing still for 30s. / s, cooled to 575°C, steel plate, then air cooled to room temperature. Then enter the heat tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com