6061-T6 aluminum alloy and TRIP980 high-strength steel dissimilar alloy resistance point welding method

An alloy resistance and resistance spot welding technology, which is applied in resistance welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of poor mechanical properties, high interlayer cost, and high brittleness of welding joints, etc., to achieve improved mechanical properties and easy tightness Adhesion, reducing the effect of welding stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The influence of embodiment 1 welding conditions on the mechanical properties of aluminum / steel spot welded joints

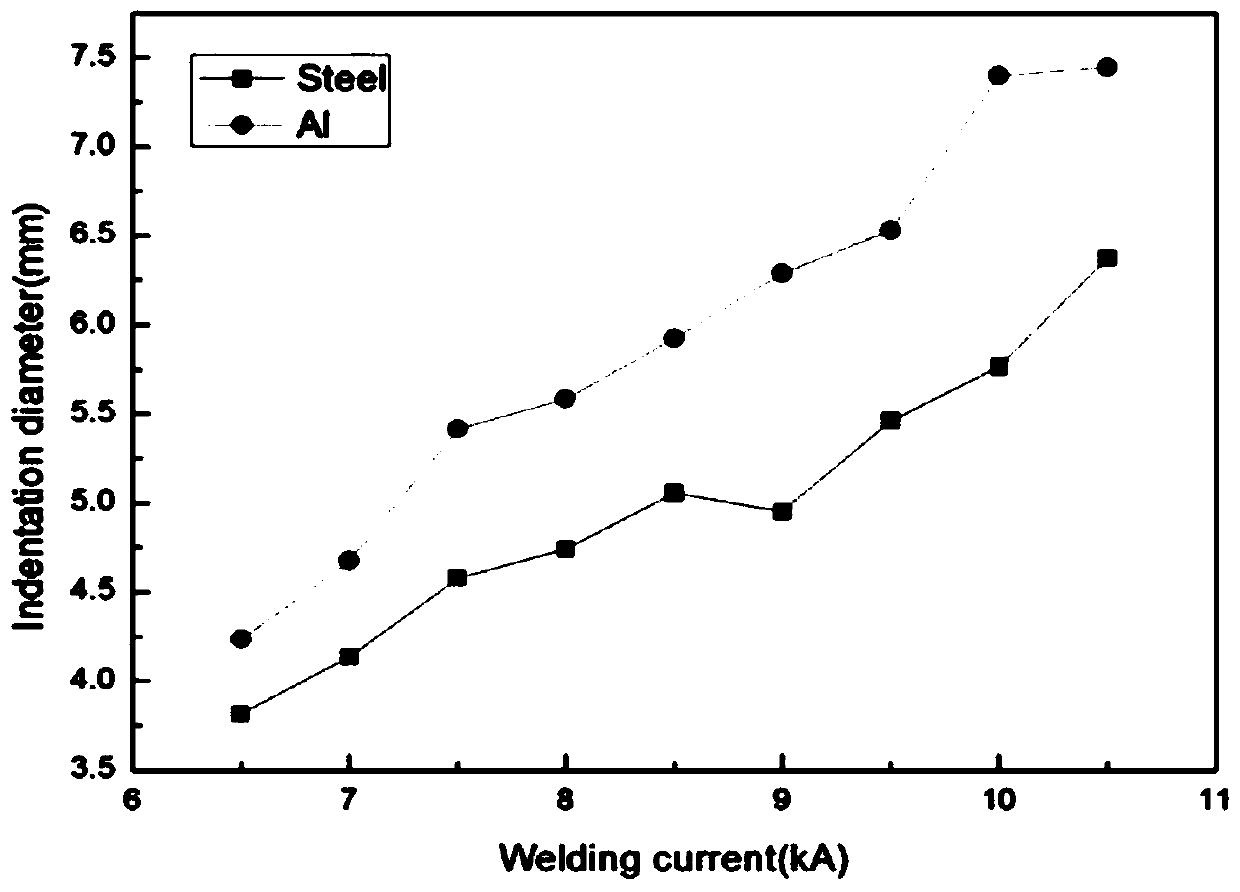

[0047] The conical flat electrode tip with a diameter of 8mm was studied according to the single factor rule, and the effects of welding current, welding time and electrode pressure on the mechanical properties of the steel / aluminum spot welded joint were studied respectively. During the experiment, three samples were welded under each set of parameters to ensure the stability of the test results. According to the tensile force and welding quality, the optimal parameters under the condition of dissimilar resistance spot welding between 6061-T6 aluminum alloy and TRIP980 high-strength steel were determined.

[0048] 1.1 Influence of welding current

[0049] Under the stable conditions of welding time (30cyc) and electrode pressure (2kN), the influence of welding current (6.5-10.5kA) on the mechanical properties of steel / aluminum dissimilar joints was st...

Embodiment 2

[0088] Example 2 Effect of Cu on the mechanical properties of aluminum / steel spot welded joints

[0089] In this example, the effects of welding current, welding time, and electrode pressure on the mechanical properties of aluminum / steel spot welded joints are studied respectively, and optimal parameters are determined according to factors such as the magnitude of the tensile force and the surface forming quality of the joint, and the spot welding Mechanism of head fracture.

[0090] 2.1.1 Influence of welding current on the mechanical properties of aluminum / steel spot welded joints

[0091] Since the addition of copper sheet increases the welding heat input, it is necessary to select larger welding parameters to achieve effective welding. Compared with no copper sheet, the welding current of 10-17kA is used sequentially, the electrode pressure is kept at 1.5kN, and the welding time is 20cycle. During the experiment, it was found that the tensile force of the spot welding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stretching force | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com