Method for welding vibration-resistant and high-temperature-resistant photomultiplier package voltage division circuit for petroleum logging

A technology of photomultiplier tube and voltage divider circuit, which can be used in welding equipment, welding/welding/cutting items, auxiliary devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

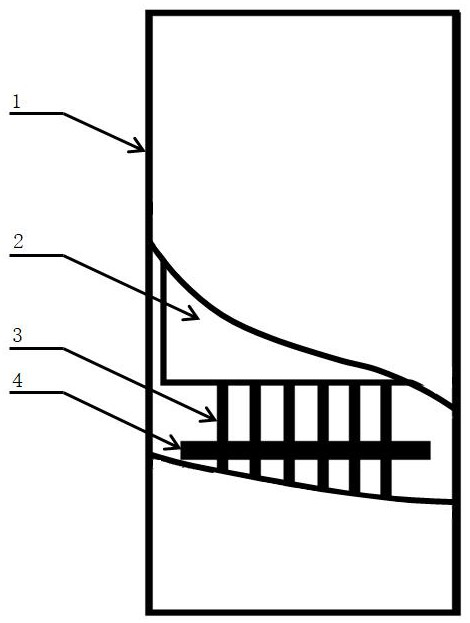

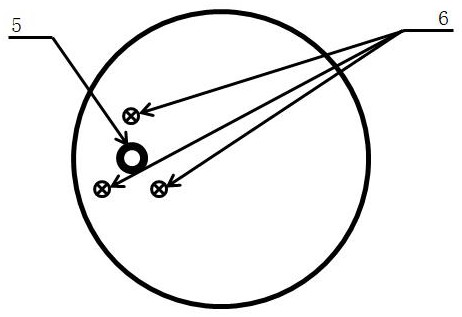

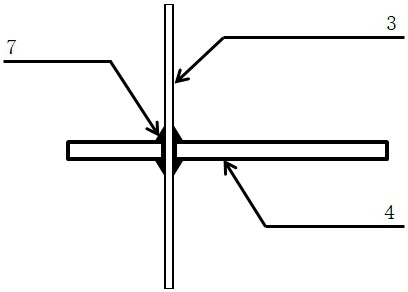

[0021] Figure 1-3 Petroleum logging anti-vibration and high-temperature resistant photomultiplier tube package voltage dividing circuit welding method, including photomultiplier tube package shell 1; photomultiplier tube 2; photomultiplier tube pin 3; ceramic voltage divider circuit board 4; through-hole pad 5; Pre-hot spot position 6; Solder spot 7.

[0022] figure 2 Shown is a schematic diagram of the preheating position in a specific embodiment of the welding method of the present invention, including the through-hole pad 5, after the photomultiplier tube needle passes through, use a soldering iron to preheat three points 6 around the through-hole pad for 5 to 7 seconds , and then place the soldering iron on the pad, and then send tin to the connection point of the tube pin and the through-hole pad for soldering.

[0023] image 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com