A processing method for a medium-sized beam of a helicopter

A processing method and helicopter technology, applied in the field of mechanical processing, can solve problems such as poor contact, poor thickness of medium beams, and poor product quality, and achieve the effect of improving product quality and solving firmness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

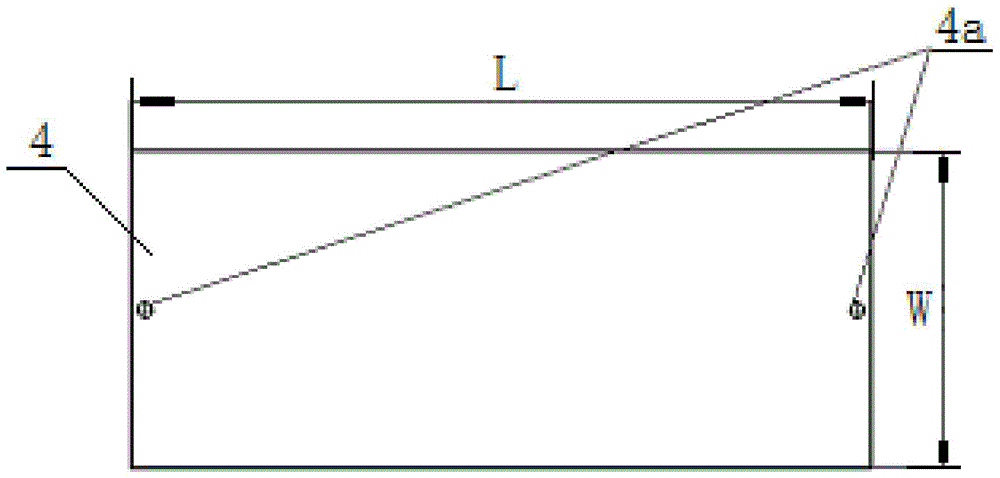

[0032] 1. Cutting: use a band saw to cut the cuboid wool 4, the length of the wool 4 is L=500+80=580mm, 500 is the maximum length of the medium-sized beam, the width of the wool 4 is W=300+80=380mm, and 300 is the length of the medium-sized beam The maximum width, the thickness of wool 4 H=60+10=70mm, 60 is the highest height of the medium-sized beam; see image 3 .

[0033] 2. Machining positioning holes: place the wool material 4 horizontally on the workbench of the CNC machine tool, process two positioning holes 4a on the wool material 4, the center of the positioning hole 4a is on the center line of the wide side of the wool material 4, and the center of the positioning hole 4a reaches the The distance of woolen 4 wide sides is 0.25x(580-500)=20mm; Refer to image 3 .

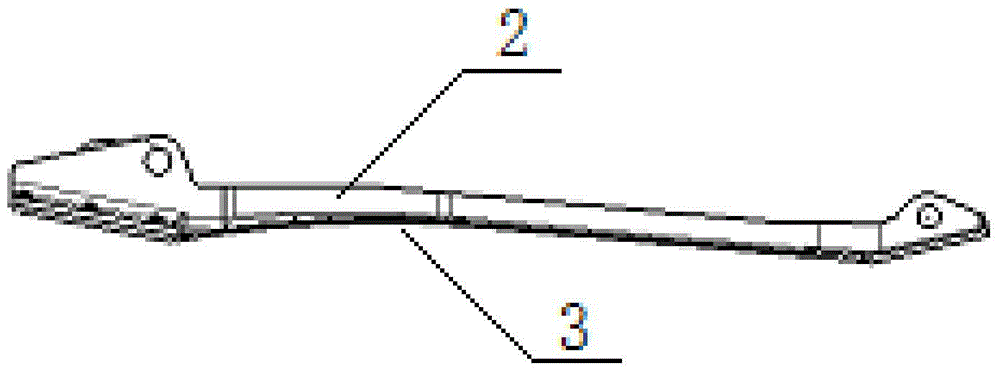

[0034] 3. Machining the lower surface 3: place the upper surface of the wool 4 downward on the workbench of the CNC machine tool, align it through the positioning hole 4a, press the four corners of the wo...

Embodiment 2

[0041] 1. Cutting: use a band saw to cut the cuboid wool 4, the length of the wool 4 is L=600+90=690mm, 600 is the maximum length of the medium-sized beam, the width of the wool 4 is W=300+80=380mm, and 300 is the length of the medium-sized beam The maximum width, the thickness of wool 4 H = 100 + 15 = 115mm, 100 is the highest height of the medium-sized beam; see image 3 .

[0042] 2. Machining positioning holes: place the wool material 4 horizontally on the workbench of the CNC machine tool, process two positioning holes 4a on the wool material 4, the center of the positioning hole 4a is on the center line of the wide side of the wool material 4, and the center of the positioning hole 4a reaches the The distance of woolen 4 wide sides is 0.25x(690-600)=22.5mm; Refer to image 3 .

[0043]3. Machining the lower surface 3: place the upper surface of the wool 4 downward on the workbench of the CNC machine tool, align it through the positioning hole 4a, press the four corners...

Embodiment 3

[0050] 1. Cutting: use a band saw to cut the cuboid wool 4, the length of the wool 4 is L=1000+100=1100mm, 1000 is the maximum length of the medium-sized beam, the width of the wool 4 is W=400+80=480mm, and 400 is the length of the medium-sized beam The maximum width, the thickness of wool 4 H = 120 + 15 = 135mm, 120 is the highest height of the medium-sized beam; see image 3 .

[0051] 2. Machining positioning holes: place the wool material 4 horizontally on the workbench of the CNC machine tool, process two positioning holes 4a on the wool material 4, the center of the positioning hole 4a is on the center line of the wide side of the wool material 4, and the center of the positioning hole 4a reaches the The distance of woolen 4 wide sides is 0.25x(1100-1000)=25mm; Refer to image 3 .

[0052] 3. Machining the lower surface 3: place the upper surface of the wool 4 downward on the workbench of the CNC machine tool, align it through the positioning hole 4a, press the four co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com