Coating process effectively improving firmness of chalcogenide glass coating film

A chalcogenide glass, fastness technology, applied in the direction of metal material coating process, coating, sputtering coating, etc., can solve the problem of easy stripping of chalcogenide glass, to increase the resistance to damage and corrosion resistance, good optical performance, the effect of increasing optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

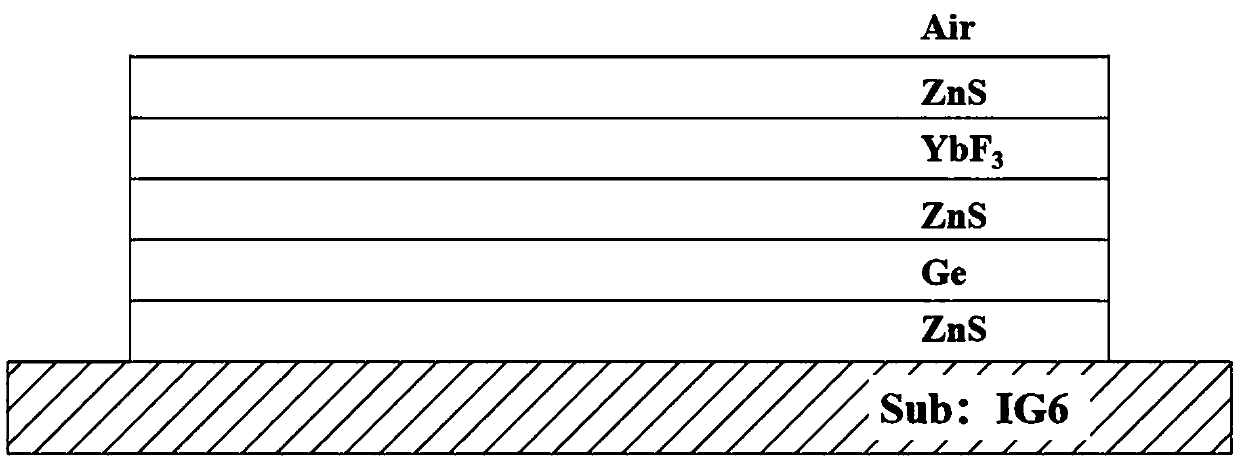

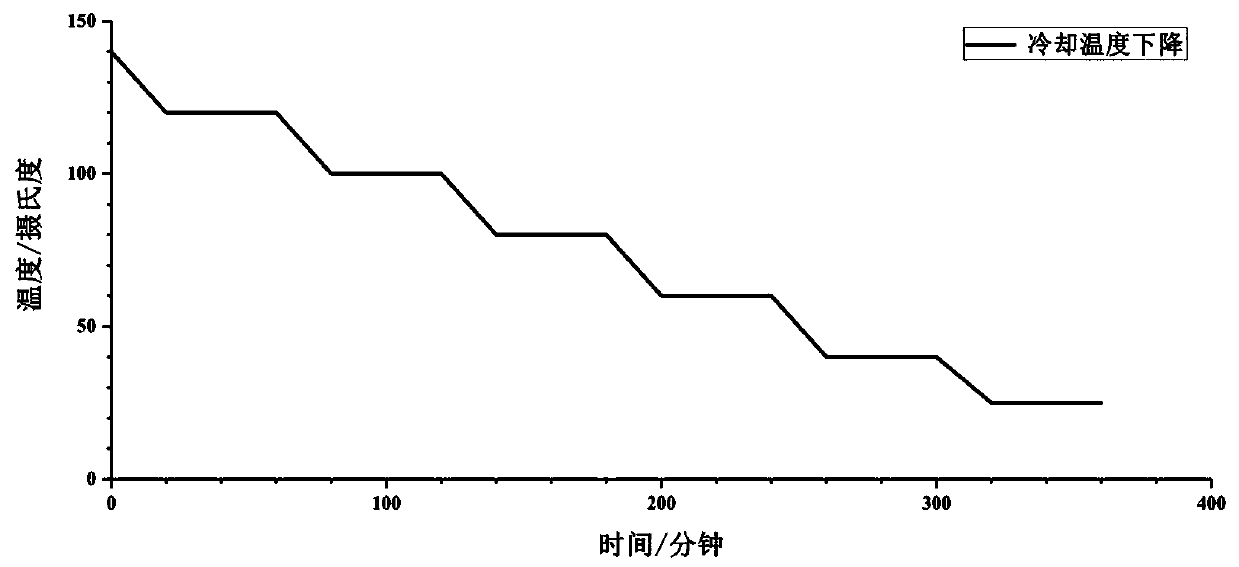

[0038] The present invention designs a coating process that effectively improves the firmness of the chalcogenide glass coating film layer, and optimizes the parameters on the basis of not changing the film structure during the coating process to solve the problem that the chalcogenide glass is easy to release the film , especially adopt the following setting method: use vacuum chamber for coating processing of chalcogenide glass, use vacuum chamber for coating processing of chalcogenide glass, the vacuum chamber is at 120-130°C (preferably 130°C) before the melting material starts, the conditions The constant temperature is not less than 30min (preferably 30min), and the ion energy parameters are both voltage 240-280V and current 7-10A when the ion source is cleaning the chalcogenide glass substrate and the ion source is helping to plate the transition layer film. They are all 260V / 8A, and are cooled by step cooling after the coating is completed.

[0039] As a preferred sett...

Embodiment 2

[0041] This embodiment is further optimized on the basis of the above embodiments, and the same parts as the aforementioned technical solutions will not be repeated here. Further, in order to better realize the present invention, the following setting methods are particularly adopted: the process method includes the following Describe the specific steps:

[0042] 1) Before melting the material, adjust the vacuum chamber to 130°C (anywhere between 120°C and 130°C, but not more than 130°C) and keep the temperature constant for 30 minutes (the constant temperature time is at least 30 minutes); the adjustment of the baking temperature is mainly to consider the sulfur system Due to the special properties of glass, the softening temperature of glass is 150°C and its thermal expansion coefficient is much higher than that of conventional materials. Therefore, during the coating process, the temperature in the vacuum chamber should be kept as stable as possible at around 150°C, taking i...

Embodiment 3

[0050] This embodiment is further optimized on the basis of any of the above-mentioned embodiments, and the same parts as the aforementioned technical solutions will not be repeated here. Further, in order to better realize the present invention, the following setting methods are adopted in particular: the step 2 ) includes the following specific steps:

[0051] 2.1) Clean the vacuum chamber, add the film material required for coating, check the activity of the crystal control plate, clean the chalcogenide glass substrate and put it into the vacuum chamber; that is, first clean the vacuum chamber, add the film material required for coating, and check the activity of the crystal control plate , soak and clean the chalcogenide glass substrate with a mixed solution of alcohol and ether 1:1, then wipe it clean with a dust-free cloth, and then put it directly on the workpiece disk lens fixture in the vacuum chamber after wiping clean;

[0052] 2.2) Close the vacuum chamber, evacuat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com