Production process of anti-porosity of non-ferrous pe pipe

A production process and anti-air hole technology, which is applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of affecting the appearance and visual effect of PE pipes, poor cooling effect of sizing, and easy generation of static electricity, etc., so as to reduce machine standby time. The effect of shortening the material time, good appearance and visual effect, and reducing the warm-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

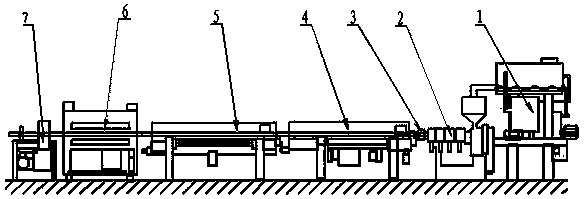

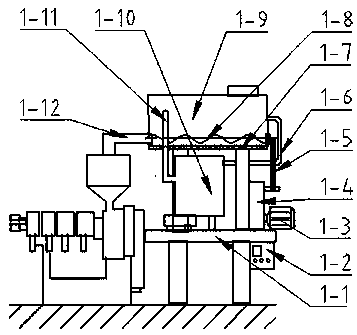

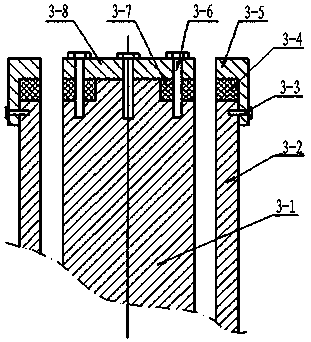

[0020] see figure 1 , figure 2 , the anti-hole production process of colored PE pipes of the present invention is as follows: first, heating and mixing with ingredients, taking 98% of polyethylene white material and 2% of color masterbatch according to the proportion by weight percentage, and putting the two raw materials into a heating mixer to carry out Heating and mixing, the heating temperature is 55°C-65°C, and the heating time is 50-60 minutes. After heating and mixing evenly, it is taken out, which is the heating mixture; the prepared heating mixture is directly sent to the heating and dehumidification on the pipe extrusion production line. In the machine 1, the heated mixture is heated and dehumidified by the heating dehumidifier 1. The temperature of the heating and dehumidification is controlled at 70-90°C, and the heating time is 30-50 minutes. The humidity of the heating mixture is <0.05%, and the heating and dehumidification is completed; The heated and dehumidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com