Production process of silica gel barrel

A production process and silica gel technology, applied in the field of silica gel barrels, can solve the problems of general molding effect and achieve good product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

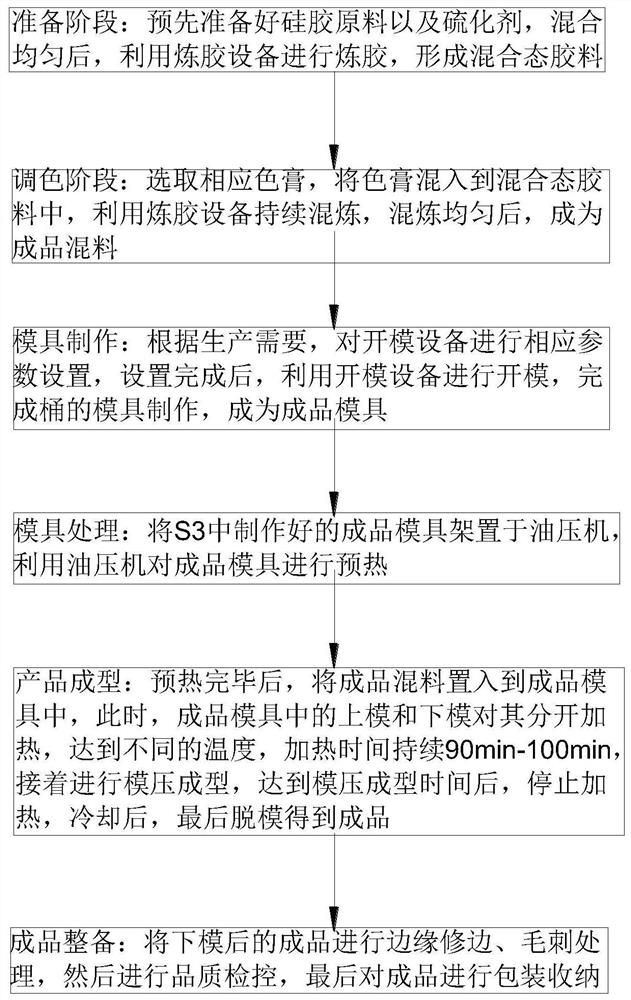

[0035] Such as figure 1 As shown, an embodiment of the present invention is presented.

[0036] The present embodiment proposes a kind of production technology of silica gel barrel, at least comprises the following steps:

[0037] S1, preparation stage: prepare the silica gel raw material and vulcanizing agent in advance, mix them evenly, and use the rubber mixing equipment to refine the rubber to form a mixed rubber material; in the actual implementation, prepare the silica gel raw material and vulcanizing agent according to the actual situation, here The raw materials of silica gel have been screened, removed impurities, cleaned, dried and other steps, so that the raw materials of silica gel have a high degree of purity. There are many kinds of vulcanizing agents on the market, and there are many manufacturers. The specific types of vulcanizing agents are not limited here, as long as they can cooperate with silica gel raw materials to achieve high-temperature vulcanization ...

Embodiment 2

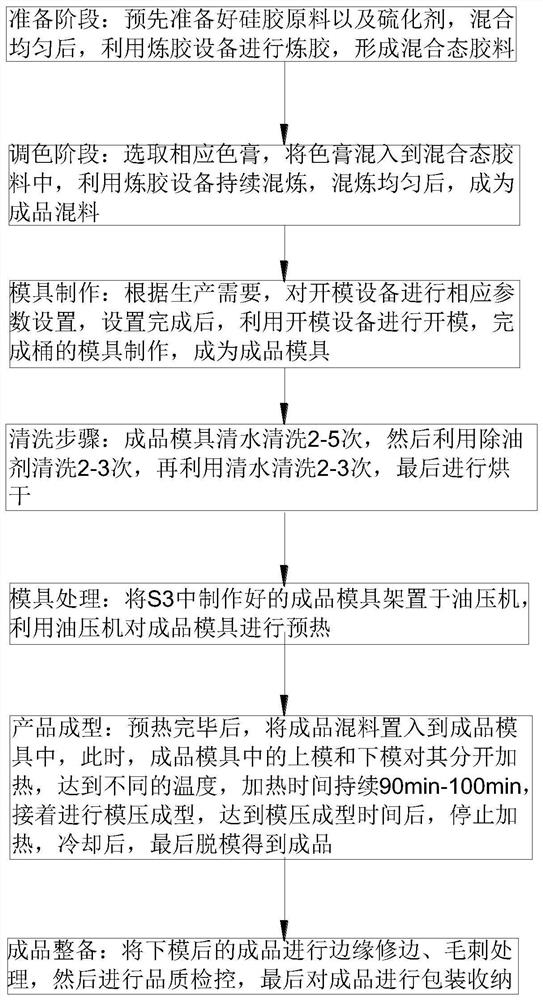

[0058] Such as figure 2 As shown, the present invention also proposes an embodiment.

[0059] In this embodiment, the preparation process of the silica gel barrel is basically the same as in Embodiment 1, the difference is that the cleaning step of the finished mold of the product is added.

[0060] In this embodiment, the above-mentioned finished mold is subjected to a cleaning step after it comes down from the mold opening equipment, including:

[0061] Wash 2-5 times with clean water, then wash 2-3 times with degreasing agent, wash 2-3 times with clean water, and finally dry. After completion, the finished mold after cleaning is placed on the hydraulic press for molding and heating operations. The first cleaning removes particles and dust, the second cleaning and removal of oil stains on the mold with a degreasing agent, and the third removing the remaining sludge and degreasing agent to clean the finished mold and ensure the molding effect of the finished product.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com