A flexible polymer film that can be used for sound intensity detection and its manufacturing method

A flexible polymer and thin-film technology, applied in measuring devices, instruments, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of inability to change shape, limited scope of application, poor transmission signal, etc., and achieve wide applicability and low cost , Good sticking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A flexible polymer film that can be used for sound intensity detection provided by an embodiment of the present invention includes conductive powder and a polydimethylsiloxane film substrate (PDMS film substrate). PDMS is polydimethylsiloxane, which is odorless, high in transparency, and has Heat resistance, cold resistance, and the viscosity changes little with temperature. The conductive powder is dispersed in the polydimethylsiloxane film matrix, the average diameter of the conductive powder can be micron or nanoscale, and the conductive powder is evenly dispersed in the polydimethylsiloxane film matrix. When the methylsiloxane film substrate is subjected to sound pressure, the shape or / and size of the polydimethylsiloxane film substrate will undergo corresponding elastic deformation, and the resistance value of the flexible polymer film will change. By monitoring the flexibility The resistance value of the polymer film can realize the detection of sound intensity, a...

Embodiment 2

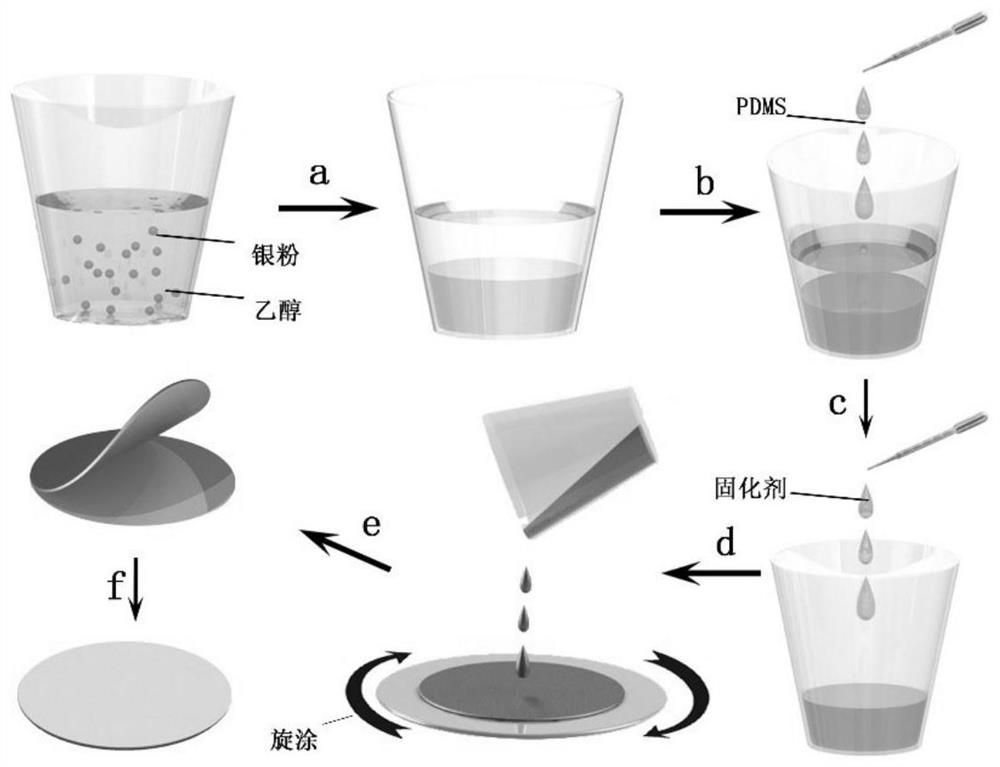

[0051] The embodiment of the present invention also provides a method for manufacturing a flexible polymer film that can be used for sound intensity detection, which can be used to manufacture the flexible polymer film that can be used for sound intensity detection described in Implementation 1. The manufacturing method includes the following steps:

[0052] Preparation of conductive powder, polydimethylsiloxane prepolymer and polydimethylsiloxane curing agent;

[0053] Adding the conductive powder to the polydimethylsiloxane prepolymer after pretreatment and mixing to obtain a blend;

[0054] Adding the polydimethylsiloxane curing agent into the mixture and mixing to obtain a solid to be cured;

[0055] The cured material is evenly spread to a set thickness and cured to obtain a flexible polymer film.

[0056] Specifically, the conductive powder can be silver powder, and the pretreatment includes the following steps:

[0057] After the silver powder is ground and refined, i...

Embodiment 3

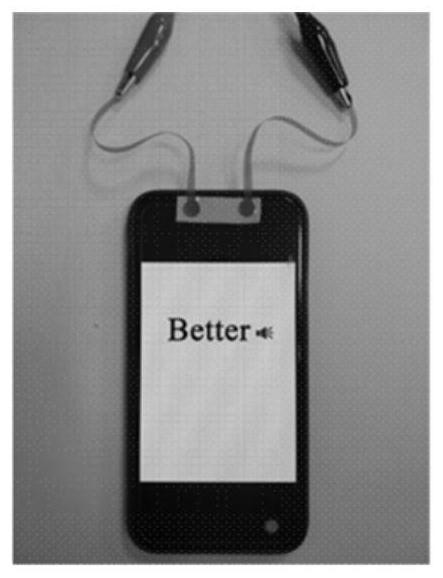

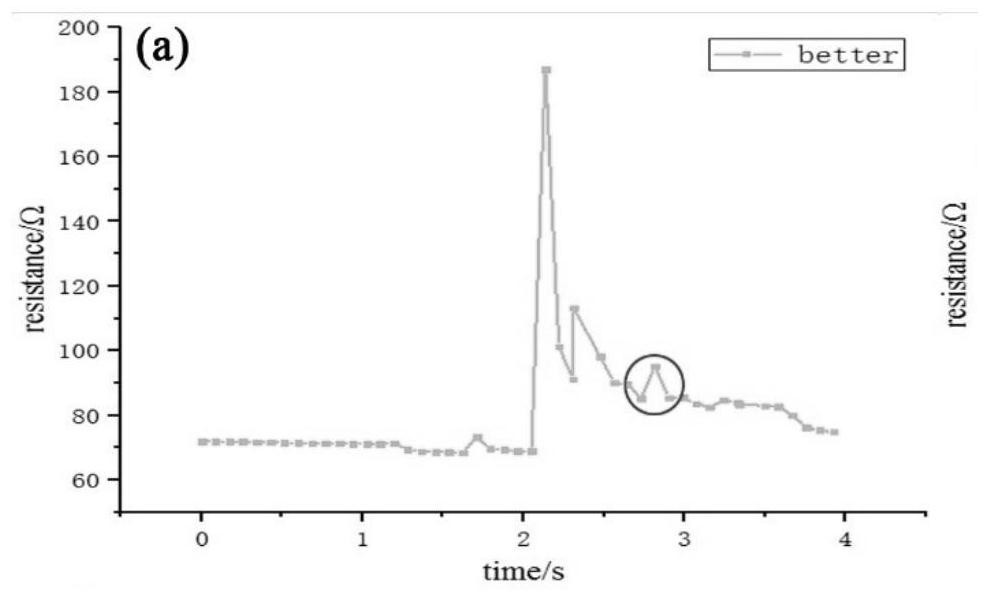

[0074] This embodiment provides a sound intensity detection device using a flexible polymer film, including a flexible polymer film and a detection module for detecting the resistance of the flexible polymer film. The flexible polymer film can be the one in Embodiment 1. Flexible polymer film for sound intensity detection. The polymer film includes conductive powder and a polydimethylsiloxane film substrate, the conductive powder is dispersed in the polydimethylsiloxane film substrate, and the detection module is connected to the Both sides of the polydimethylsiloxane film substrate. The detection module can be a voltage detection module or a current detection module. That is, according to Ohm's law, a set current is applied, and the voltage of the flexible polymer film electrode is detected by the voltage detection module, so that the resistance value of the flexible polymer film can be obtained. Alternatively, a set voltage is applied to detect the current of the flexible ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com