Manufacturing method for high-purity aluminum rotating target

A manufacturing method and a technology of rotating targets, which are applied in the field of TFT target material manufacturing, can solve the problems of small material extrusion ratio, low maximum extrusion force, difficult refinement and uniformity of tube billet grain size, and achieve processing accuracy effect of satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

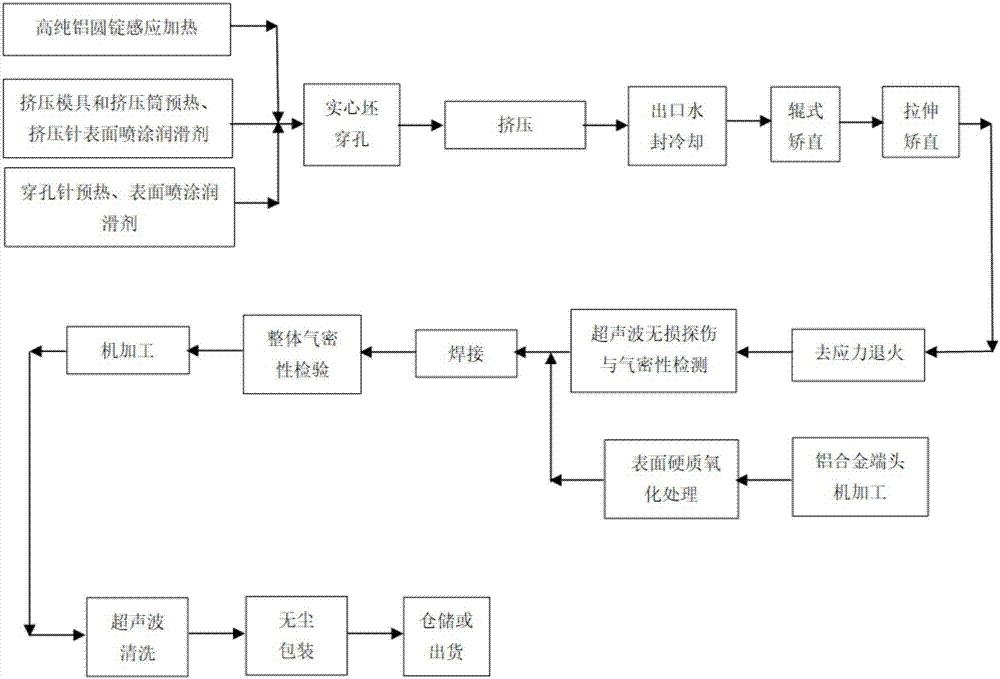

[0033] see figure 1 , which is a process flow chart of the manufacturing method of the high-purity aluminum rotating target in this embodiment, specifically including the following steps:

[0034] (1) Choose a high-purity aluminum ingot with a purity of 99.999% as the target material, and its specifications are: outer diameter 450mm, length 580-850mm; choose a reverse extrusion machine for extrusion, and the diameter of the inner hole of the extrusion cylinder is 460mm , the diameter of the perforating needle is 125mm; the high-purity aluminum round ingot is placed in a power frequency induction heating furnace for heating, the heating temperature is 150°C-350°C, and the holding time is 0.5-2.0 hours to obtain a solid high-purity aluminum billet; Before extrusion, preheat the extrusion die, extrusion barrel and piercing hole. The preheating temperature of the extrusion barrel and extrusion die is 300-350°C, and the preheating temperature of the piercing needle is 100-350°C; A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com