Styrofoam member and sound-absorbing panel with the same

A foamed polystyrene and sound-absorbing panel technology, which is applied to building components, sound insulation, elastic floors, etc., can solve problems such as easy damage of protrusions, and achieve the effect of low probability of damage, not easy to be damaged, and enhanced sound-absorbing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

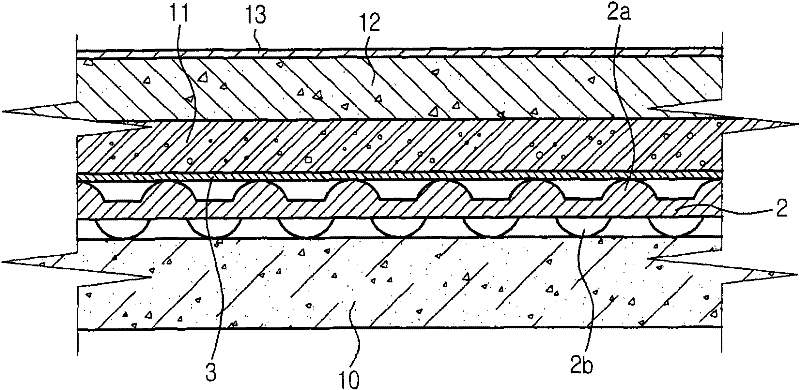

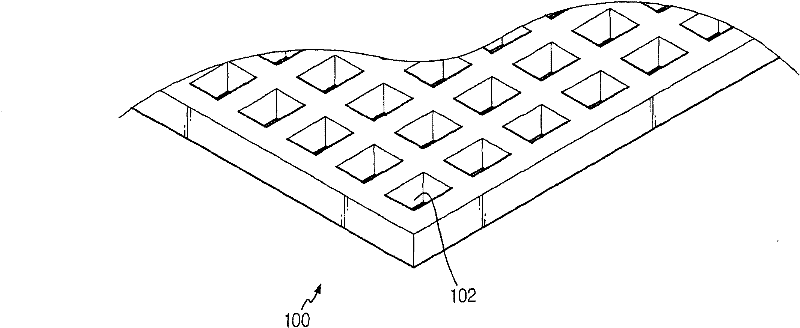

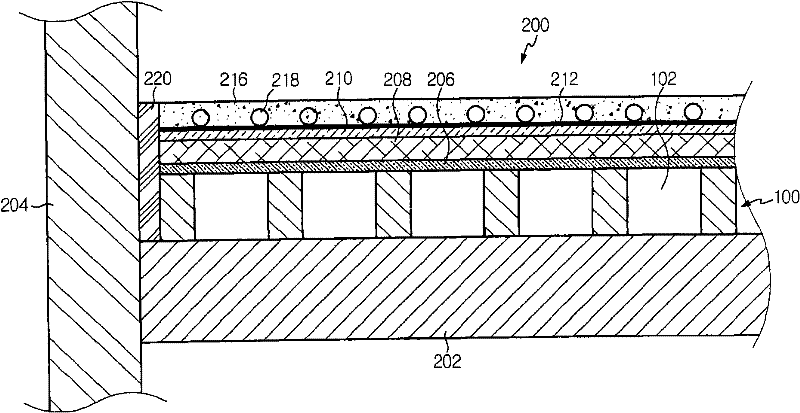

[0030] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. figure 2 is a partial perspective view showing a styrofoam member for a sound-absorbing panel installed in a floor according to an embodiment of the present invention, and image 3 is shown with figure 2 A partial cross-sectional view of an acoustic panel with styrofoam components.

[0031] The styrofoam member 100 for a sound-absorbing panel at a floor according to the present invention has a plurality of holes 102 with a space ratio of 60% to 90% and a dynamic modulus of elasticity of 25MN / m 3 up to 45MN / m 3 . exist figure 2 In the figure, the hole 102 is illustrated as a rectangular shape, but the hole 102 may also be in other shapes, such as a circle, an ellipse, or a polygon other than a rectangle. If the styrofoam member 100 having the above-mentioned space ratio has a dynamic elastic modulus smaller than the lower limit, peo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com