Device for microwave plating of nano-diamond film

A nano-diamond and microwave technology, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of simple structure, etc., and achieve the effect of less porosity, excellent coating quality and good adaptability of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

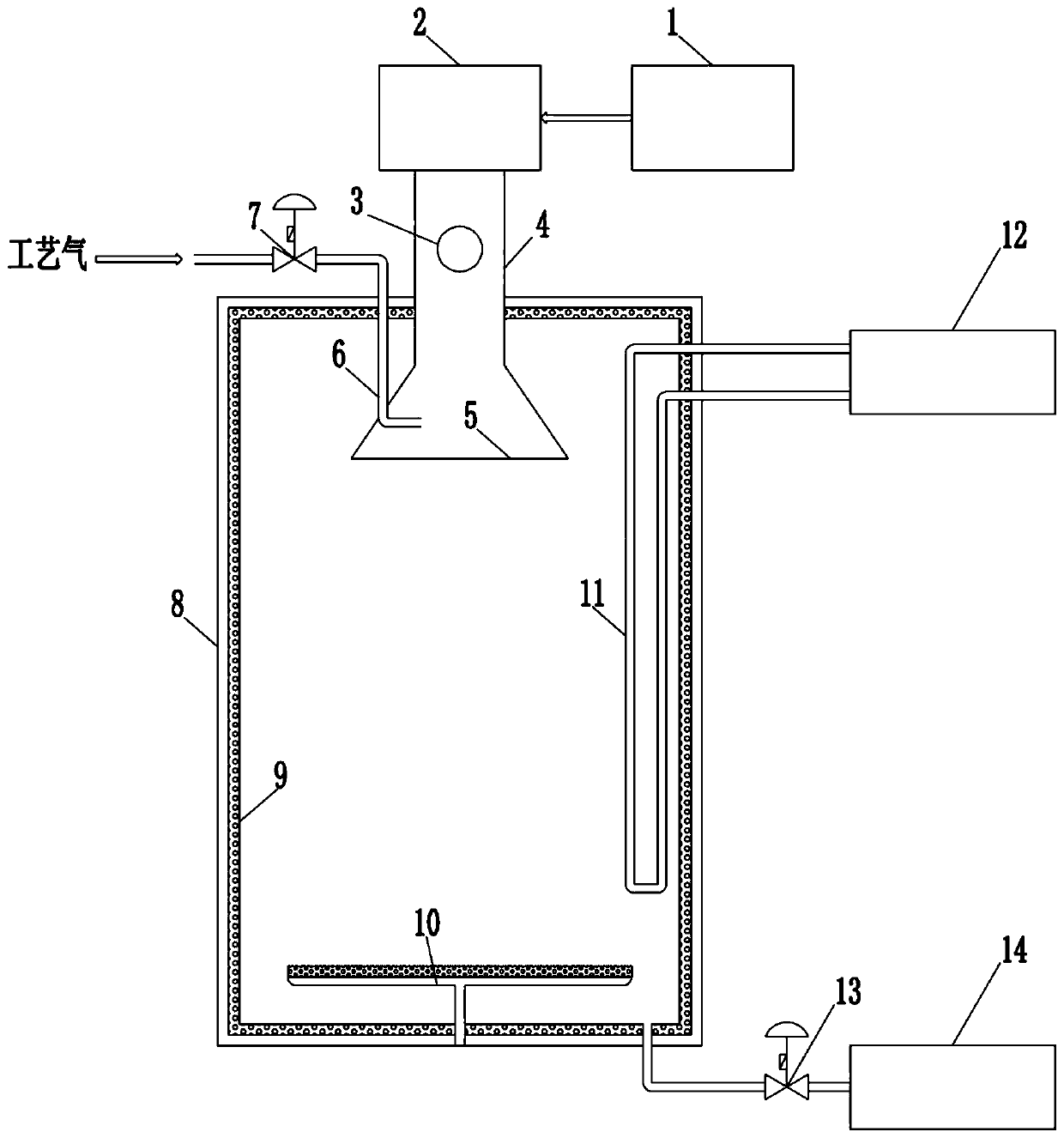

[0032] Such as figure 1 Shown: a microwave nano-diamond film coating equipment, which mainly consists of a microwave generator 100, a microwave transmitting horn 5, a process inlet pipe 6, a process control valve 7, a microwave shielding layer 9, a rotating tray 10, a cooling coil 11, The water cooling system 12, the exhaust valve 13, the vacuum system 14 and the coating housing 8 are composed, wherein the coating housing 8 is a cavity with sealing performance. Vacuum system 14 is conventional system equipment in this field, and is generally a complete set of vacuum system composed of vacuum pump, PLC program control system, gas storage tank, vacuum pipeline, vacuum valve, external filter assembly, etc. The water cooling system 12 is also conventional equipment in the field, such as water tank / water tank and water pump, so that the circulating water cooling system is composed of water tank / water tank, water pump and cooling coil.

[0033] The microwave generator 100 described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com