Solder resist composition and printed circuit board having cured product thereof

A printed circuit board, solder resist technology, applied in the directions of printed circuit, printed circuit manufacturing, printed circuit secondary treatment, etc., can solve the problems of expansion and peeling, solder resist voids or cracks, and solder resist composition flow out, etc., and achieve cavitation. Good resistance, less voids and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

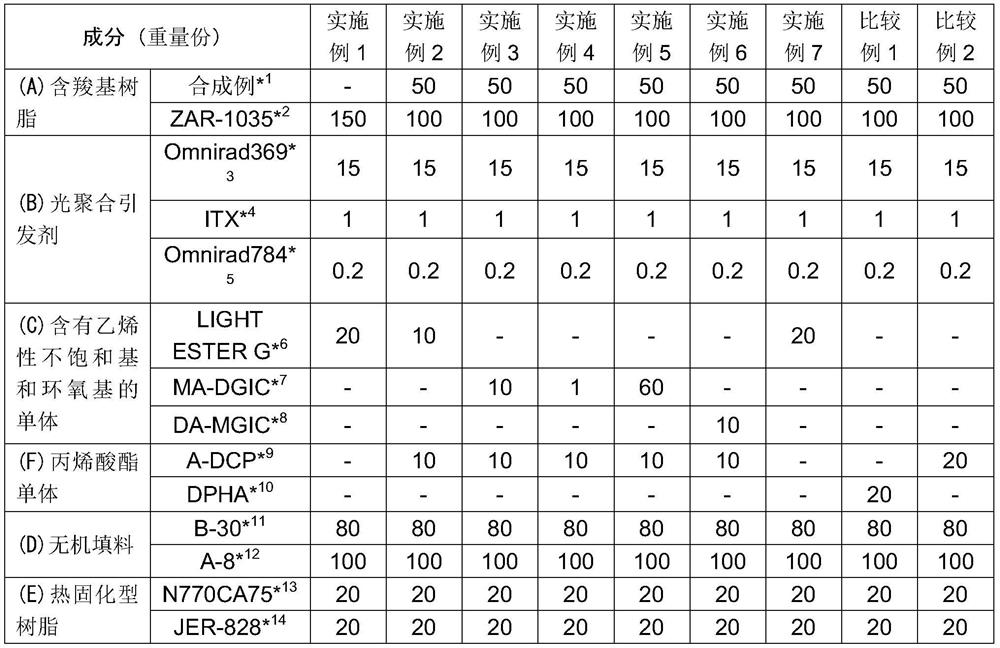

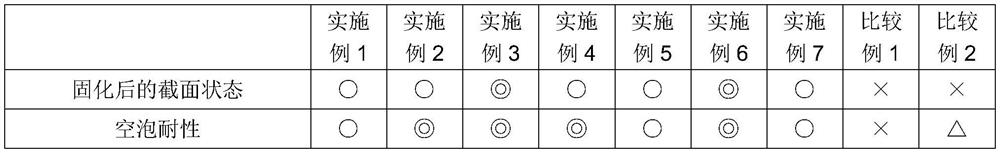

Embodiment 1~6 and comparative example 1~2

[0123] Each component was blended in the compounding composition shown in Table 1 (values are parts by mass), and kneaded with a 3-roll mill to prepare an alkali-soluble photocurable resin composition. In addition, (A) carboxyl group-containing resin in Table 1 is 100 weight part in conversion of solid content.

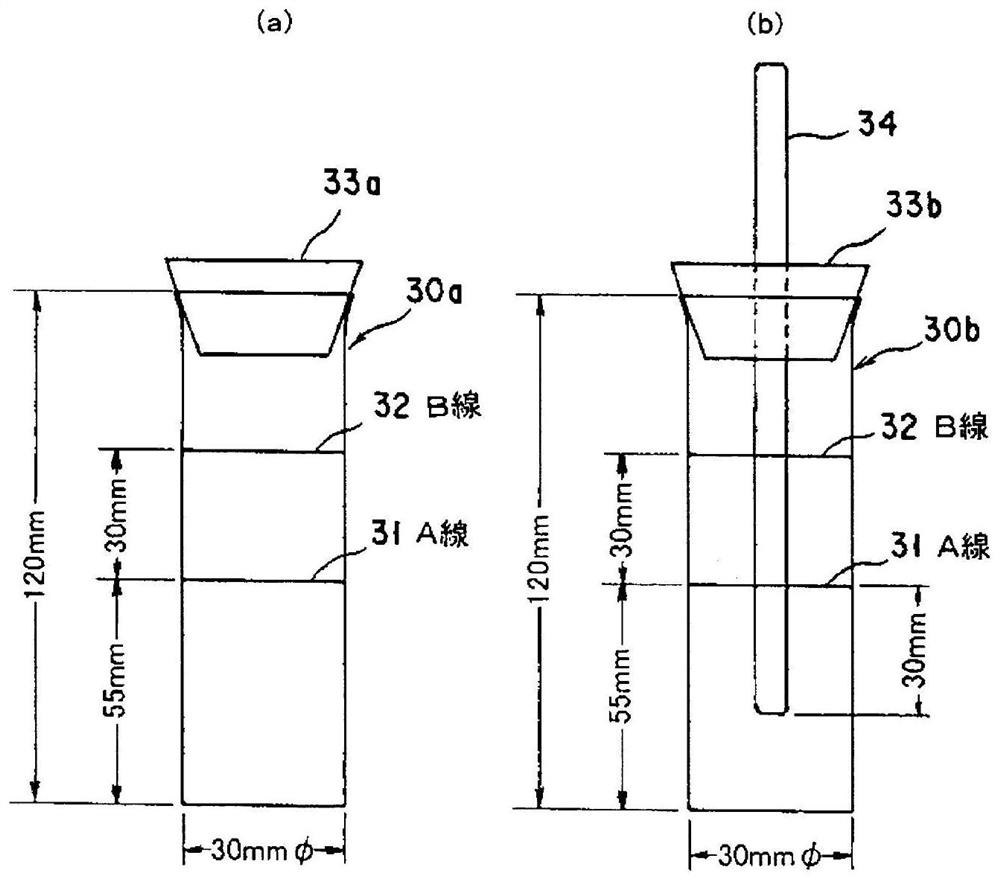

[0124] A photocurable resin composition was printed on a through-hole substrate having a plate thickness of 1.6 mm and a hole diameter of 0.25 mm by a screen printing method using a 90-mesh polyester screen formed with a pattern capable of filling through holes. Furthermore, both surfaces were coated over the entire surface with a 90-mesh polyester screen, and dried for 30 minutes with a 75° C. hot air drier.

[0125] Then, using HMW-680GW of ORC Co., Ltd., at 500J / cm 2 The exposure amount is exposed to UV curing of the coating film. Then, heat curing was performed at 80° C. for 30 minutes, 110° C. for 30 minutes, and 150° C. for 40 minutes with a hot air circulat...

Synthetic example 1

[0127] In a 2-liter separable flask equipped with a stirrer, thermometer, reflux condenser, dropping funnel, and nitrogen line, add 900 parts of diglyme as a solvent, 21.4 parts of peroxide 2 - Tert-butyl ethylhexanoate (PERBUTYL O manufactured by NOF Corporation) was heated to 90°C. After heating, 309.9 parts of methacrylic acid, 116.4 parts of methyl methacrylate, 109.8 parts of lactone-modified 2-hydroxyethyl methacrylate (PLACCEL FM1 manufactured by DAICEL CHEMICAL INDUSTRIES, LTD.) and 21.4 parts were used as polymerization initiators. Bis(4-tert-butylcyclohexyl)peroxydicarbonate (PEROYL TCP manufactured by NOF Co., Ltd.) was added dropwise thereto over a total of 3 hours, followed by aging for 6 hours to obtain a carboxyl group-containing copolymer resin. It should be noted that this reaction was carried out under a nitrogen atmosphere.

[0128] Then, 363.9 parts of 3,4-epoxycyclohexylmethyl acrylate (CYCLOMER A200 manufactured by DAICEL CHEMICAL INDUSTRIES, LTD.), 3.6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com