Method for spraying enamel coating on titanium alloy surface through plasma technique and hot rolling treatment

A surface plasma and plasma technology, applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems that cannot be directly used as spraying materials, poor fluidity, small powder particle size, etc., to achieve tight combination and reduce Pores and cracks, less porosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

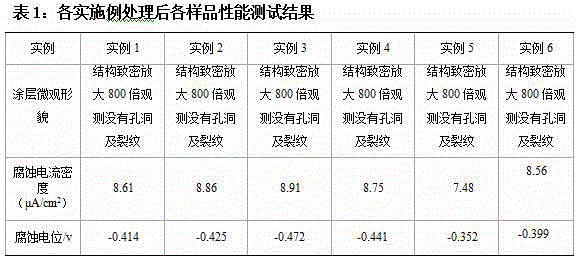

Examples

Embodiment 1

[0017] Add 10% water and 3.5% polyacrylic acid dispersant to the prepared enamel powder to make it into a jelly. The volume fraction of solid matter in the jelly is 25%. The jelly is stirred for 10 minutes by mechanical stirring method. After stirring, use a hot air blower to dry the jelly. The efficiency of the hot air drying water is 7 kg / h. The particle size obtained after air drying is sprayed on the Ti-6Al-4V titanium alloy as a plasma spraying material. During the plasma spraying process, argon and a small amount of hydrogen are used as the main plasma spraying gas, and helium is used as a protective gas. After spraying, the sample was subjected to hot rolling treatment. The starting temperature was 300°C. After the sample was kept at 300°C for 30 minutes, it was rolled. There were 3 passes in total, and the total rolling ratio was 10%. The sample was placed in a tube furnace for annealing treatment under a hydrogen atmosphere at an annealing temperature of 500°C, and th...

Embodiment 2

[0019] Add 10% water and 3.5% polyacrylic acid dispersant to the prepared enamel powder to make it into a jelly. The volume fraction of solid matter in the jelly is 30%. The jelly is stirred for 15 minutes by mechanical stirring method. After stirring, use a hot air blower to dry the jelly. The efficiency of the hot air drying water is 7 kg / h. The particle size obtained after air drying is sprayed on the Ti-6Al-4V titanium alloy as a plasma spraying material. During the plasma spraying process, argon and a small amount of hydrogen are used as the main plasma spraying gas, and helium is used as a protective gas. After spraying, the sample was hot-rolled. The rolling temperature was 450°C. After the sample was kept at 450°C for 30 minutes, it was rolled. There were 4 passes in total, and the total rolling ratio was 15%. The sample was placed in a tube furnace for annealing treatment under a hydrogen atmosphere at an annealing temperature of 600°C, and the sample was cooled with ...

Embodiment 3

[0021] Add 10% water and 3.5% polyacrylic acid dispersant to the prepared enamel powder to make it into a jelly. The volume fraction of solid matter in the jelly is 35%. The jelly is stirred for 20 minutes by mechanical stirring method. After stirring, use a hot air blower to dry the jelly. The efficiency of the hot air drying water is 7 kg / h. The particle size obtained after air drying is sprayed on the Ti-6Al-4V titanium alloy as a plasma spraying material. During the plasma spraying process, argon and a small amount of hydrogen are used as the main plasma spraying gas, and helium is used as a protective gas. After spraying, the sample was hot-rolled. The rolling temperature was 550°C. After the sample was kept at 550°C for 30 minutes, it was rolled. There were 4 passes in total, and the total rolling ratio was 20%. The sample was placed in a tube furnace for annealing treatment under a hydrogen atmosphere, the annealing temperature was 650°C, and the sample was cooled with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com