Method and device for controlling austenite grain size of continuous casting slab, and product

A technology of austenite grain and control method, applied in the field of metallurgical continuous casting, can solve problems such as affecting the surface quality of the casting billet, and achieve the effects of preventing narrow-face crack defects, reducing temperature gradients, and reducing shrinkage stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

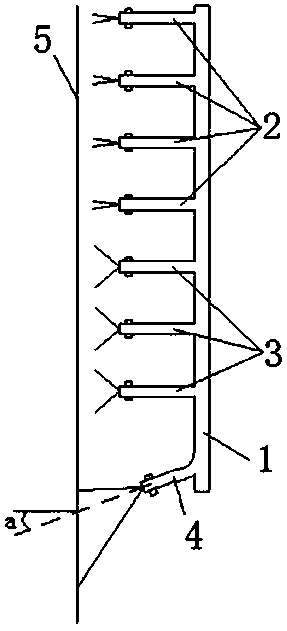

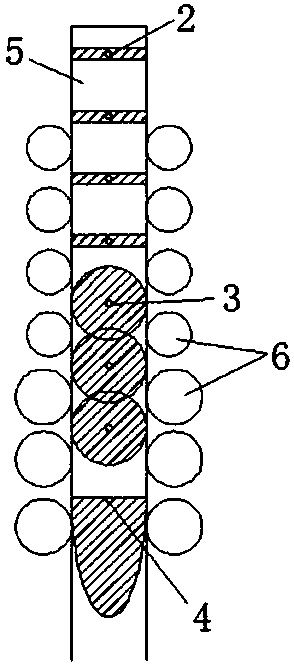

[0028] The continuous casting machine used in the specific embodiment is a straight arc conventional slab continuous casting machine, the metallurgical length is 33.2m, the arc radius is 10.9m, and it is composed of 15 sector sections, of which 2 sections are curved sections and 9 sections are straightening Straight section, casting machine annual production capacity is 2.8 million tons / year.

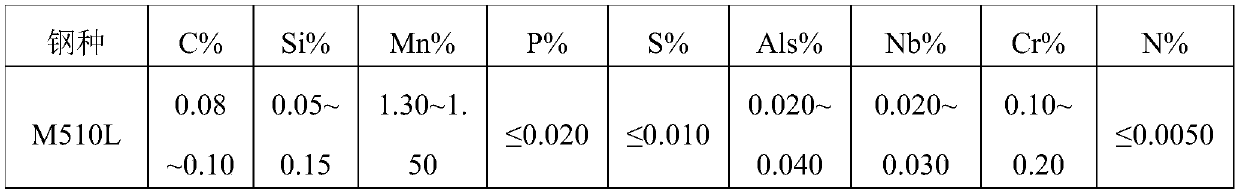

[0029] Select the steel type M510L, its target composition is shown in the table below, and the section of the continuous casting slab is 230×1600mm.

[0030]

[0031] Steelmaking - molten steel with qualified refining composition and cleanliness is continuously passed through the crystallizer and the secondary cooling section through the protection casting of "large ladle + long nozzle" and "tandem ladle + submerged nozzle". According to the steel type, the crystallizer taper is set to 1.10%, the casting speed is controlled at 1.30m / min, the crystallizer adopts fast cooling, the wat...

Embodiment 2

[0036] A control method, device and product for continuous casting slab austenite grains. Except following technical parameter, all the other are with embodiment 1.

[0037] Select the steel type M590L, its target composition is shown in the table below, and the section of the continuous casting slab is 230×1800mm.

[0038]

[0039]The water flow velocity of the wide surface and narrow surface tanks is 6.9m / s and 7.2m / s respectively, and the water temperature at the entrance is controlled at 26-28°C;

[0040] Vertical section wide surface water is 433L / m 2 , the water volume of narrow face foot roll is 448L / m 2 .

[0041] The third nozzle 4 faces downwards, its centerline is in a vertical plane and the included angle a with the horizontal plane is 20°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com