Treatment method for improving acid corrosion resistance of chemical pump shaft

A treatment method and corrosive technology, which is applied in the treatment field of improving the acid corrosion resistance of chemical pump shafts, can solve the problems that the acid corrosion resistance of chemical pump shafts cannot meet the requirements, and the performance of chemical pump shafts affects the efficiency of chemical pumps. Achieve the effects of strengthening acid corrosion resistance, improving surface quality, and uniformly refining grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

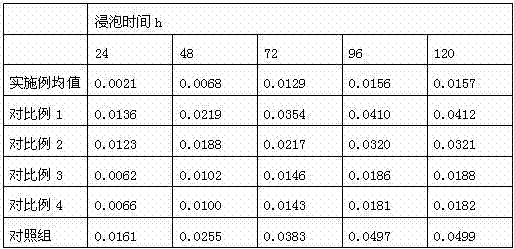

Examples

Embodiment 1

[0014] A treatment method for improving the acid corrosion resistance of a pump shaft of a chemical pump, comprising the following steps:

[0015] (1) First, the pump shaft is subjected to solid solution treatment in an electric furnace. The specific conditions of the solid solution treatment are to preheat at a heating rate of 200 °C / h to 400 °C for 36 minutes, and then at a heating rate of 80 °C / h The heating rate is heated to the treatment temperature of 1040°C, the treatment time is 72 minutes, and high-purity nitrogen gas is introduced at the 40th minute of treatment. A high-current pulsed ion beam composed of a mixed ion beam of 78 ns is used to irradiate the surface of the treated pump shaft. The number of irradiations is 2 times, the first irradiation time is 15s, the second irradiation time is 12s, and then Then cool the pump shaft at a cooling rate of 1.5 °C / s to 150 °C quickly, keep it warm for 56 minutes, then air cool to room temperature, and then heat the pump sh...

Embodiment 2

[0022] A treatment method for improving the acid corrosion resistance of a pump shaft of a chemical pump, comprising the following steps:

[0023] (1) First, the pump shaft is subjected to solid solution treatment in an electric furnace. The specific conditions of the solid solution treatment are to preheat at a heating rate of 200 °C / h to 420 °C for 36 minutes, and then at a heating rate of 80 °C / h The heating rate is heated to the treatment temperature of 1080°C, the treatment time is 72 minutes, and high-purity nitrogen gas is introduced at the 40th minute of treatment. A high-current pulsed ion beam composed of a mixed ion beam of 78 ns is used to irradiate the surface of the treated pump shaft. The number of irradiations is 2 times, the first irradiation time is 15s, the second irradiation time is 12s, and then Then cool the pump shaft at a cooling rate of 1.5 °C / s to 150 °C quickly, keep it warm for 56 minutes, then air cool to room temperature, and then heat the pump sh...

Embodiment 3

[0030] A treatment method for improving the acid corrosion resistance of a pump shaft of a chemical pump, comprising the following steps:

[0031] (1) First, the pump shaft is subjected to solid solution treatment in an electric furnace. The specific conditions of the solid solution treatment are to preheat at a heating rate of 200 °C / h to 410 °C for 36 minutes, and then at a heating rate of 80 °C / h The heating rate is heated to the treatment temperature of 1060 ° C, the treatment time is 72 minutes, and high-purity nitrogen gas is introduced at the 40th minute of treatment, and the pressure of nitrogen gas is 21 MPa. A high-current pulsed ion beam composed of a 78ns mixed ion beam is used to irradiate the surface of the treated pump shaft. The number of irradiations is 2 times, the first irradiation time is 15s, the second irradiation time is 12s, and then Then cool the pump shaft at a cooling rate of 1.5 °C / s to 150 °C quickly, keep it warm for 56 minutes, then air cool to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com