Austenite-bainite alloy steel and preparation method thereof

A technology of alloy steel and austenite, which is applied in the field of Austenitic alloy steel and its preparation, can solve the problems of limited toughness improvement ability, and achieve the effect of high strength, good plasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

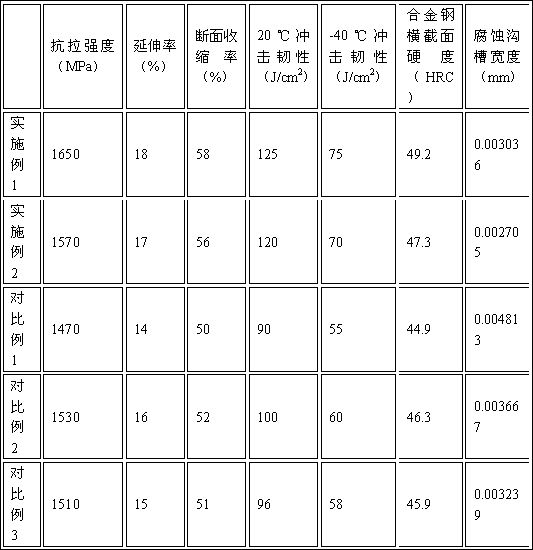

Examples

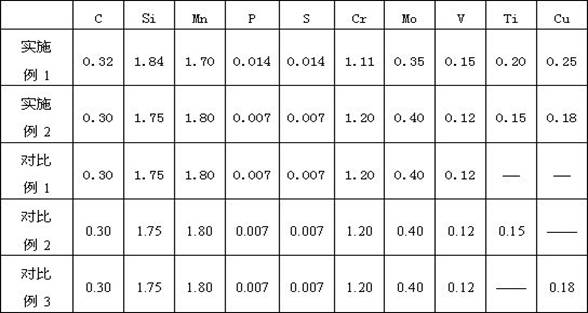

Embodiment 1

[0029] An austenite alloy steel, the alloy steel comprising austenite and bainite, the composition of the alloy steel is calculated according to mass percentage, including: C: 0.32; Si: 1.84; Mn: 1.70; P: 0.014 ; S: 0.014; Cr: 1.11; Mo: 0.35; V: 0.15; Ti: 0.10~0.20; Cu: 0.10~0.25; the balance is Fe and inevitable gas impurity elements.

[0030] The inevitable gas impurity elements need to be strictly controlled: [O] ≤ 10ppm, [H] ≤ 1.0ppm, [N] ≤ 70ppm.

[0031] The content of Ti and Cu in the alloy steel is calculated by mass percentage, and is preferably 0.2 and 0.25, respectively.

[0032] A preparation process of austenitic alloy steel, the specific steps are as follows:

[0033] (1) Material preparation: Weigh the corresponding materials according to the alloy steel composition in Example 1. The total weight of the materials is calculated according to 500Kg. After weighing, they are placed in an electric furnace or a converter for smelting;

[0034] (2) Electric furnace or converter...

Embodiment 2

[0042] The difference from embodiment 1 is that an austenitic alloy steel, the structure of the alloy steel includes austenite and bainite, and the composition of the alloy steel is calculated according to mass percentage, including: C: 0.30; Si : 1.75; Mn: 1.80; P: 0.007; S: 0.007; Cr: 1.2; Mo: 0.40; V: 0.12; Ti: 0.10~0.20; Cu: 0.10~0.25; the balance is Fe and inevitable gas impurity elements . In addition, the content of Ti and Cu in the alloy steel is calculated by mass percentage, and is preferably 0.15 and 0.18, respectively.

[0043] The role of each component of alloy steel is as follows:

[0044] The role of C, C is a strong interstitial solid solution strengthening element, which is very important to the strength, hardness and toughness of steel. As the carbon content increases, the strength and hardness of the steel increase, and the toughness and weldability decrease. Carbon is an element that stabilizes austenite, because it has a large solubility in austenite and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com