A method for improving the comprehensive performance of ultra-high-strength aluminum alloys by combining two-pass ecap processing

A comprehensive performance, aluminum alloy technology, applied in the field of combining two-pass ECAP processing to improve the comprehensive performance of ultra-high strength aluminum alloys Corrosion performance improvement and strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

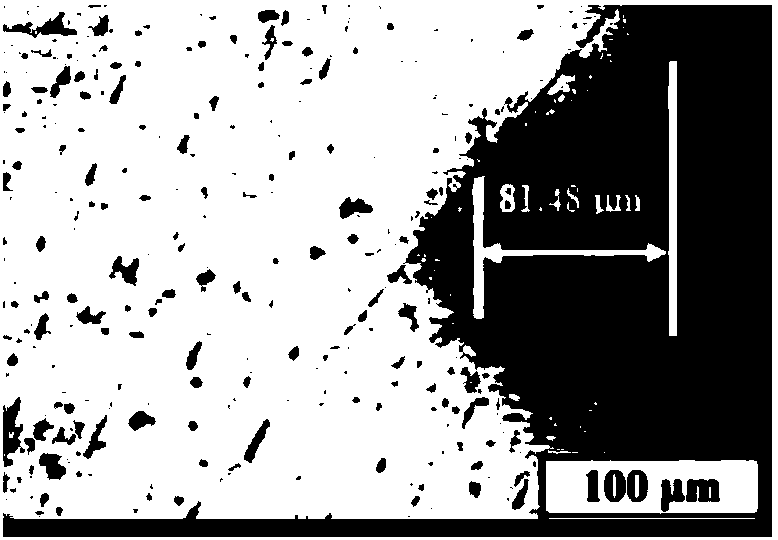

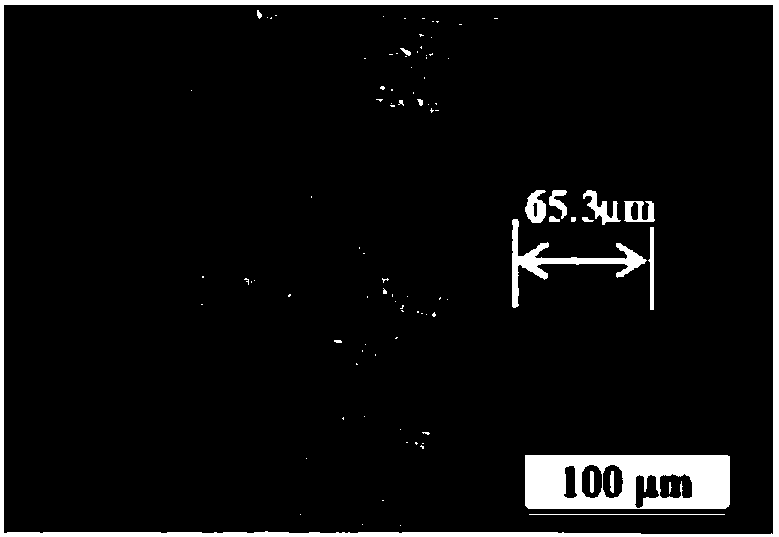

Image

Examples

Embodiment 1

[0025] A method for improving the comprehensive properties of an ultra-high-strength aluminum alloy (Al-12.18Zn-3.31Mg-1.43Cu-0.20Zr-0.0435Sr), comprising the following steps:

[0026] First, cut and sample the workpiece, and then perform overaging treatment. The overaging process is (400±10)°C×(48±1)h, and then heat the sample to 420±10°C (preheating the mold To be realized), and after 2±0.5h of heat preservation, put it into the ECAP mold for two passes of C-mode ECAP processing. After one ECAP process, the sample needs to be rotated 180° around the axis, and then the sample is heated to 420±10°C (which can be achieved by preheating the mold), and after 2±0.5h of heat preservation, the second Pass ECAP processing. In order to prevent the sample from cracking during the extrusion process, a layer of copper sleeve can be wrapped around the sample to protect the sample. After the ECAP processing is completed, the sample needs to be heated to 420±10°C and held for 2±0.5h, and ...

Embodiment 2

[0032]A method for improving the comprehensive performance of an ultra-high-strength aluminum alloy (Al-12.18-12.51Zn-2.85-3.31Mg-1.43-2.83Cu-0.18-0.20Zr-0.0435-0.0598Sr), comprising the following steps:

[0033] Cut and sample the ultra-high-strength aluminum alloy with a mass fraction of , and then perform overaging treatment. The overaging process is 400±10℃×48±1h, and then put the sample into the ECAP mold for two passes B C Mode ECAP processing. After one ECAP process, the sample needs to be rotated 90° around the axis, and then the second ECAP process is performed. Before the second pass of ECAP processing, the sample needs to be heat-preserved at 420±10℃×2±0.5 h, and the mold should be preheated. In order to prevent the sample from cracking during the extrusion process, a layer of copper sleeve should be wrapped around the sample to protect the sample. After the ECAP processing is completed, the sample needs to be heated to 420±10°C and kept for 2±0.5h, and then subje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com